Production Method of Material Film and Production Apparatus of Material Film

a production method and film technology, applied in the field of material film production method and production apparatus of material film, can solve the problems of inability to control collision energy, and inability to achieve the effects of improving controllability of material film production process, good efficiency, and accurately measuring ions density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first concrete example

Ion Implantation Scheme

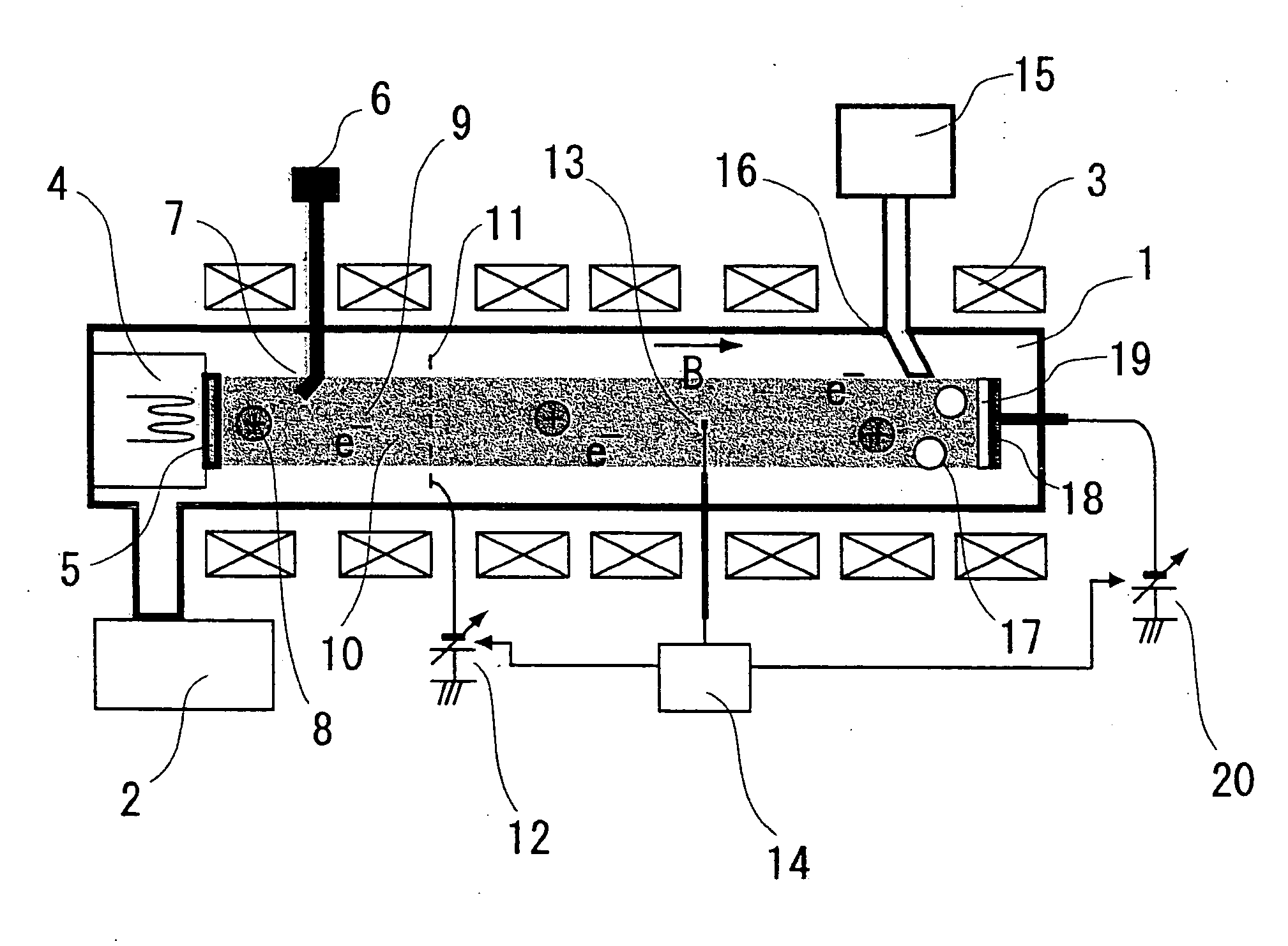

[0163]FIG. 1 is a cross-sectional view of a material film production apparatus according to a first concrete example of the present invention. The first concrete example is a containing-fullerene production apparatus configured to implant alkali metal ions into fullerene to thereby produce alkali-metal-containing fullerene.

[0164]The production apparatus is constituted of a vacuum vessel 1, an electromagnetic coil 3, alkali metal plasma generation means, a grid electrode 11, a plasma prove 13, fullerene vapor deposition means, a deposition-assistance substrate 18, and a bias voltage control power supply 20.

[0165]The vacuum vessel 1 is evacuated to a degree of vacuum of about 10−4 Pa by a vacuum pump 2. The plasma generation means is constituted of a heating filament 4, a hot plate 5, an alkali metal sublimation oven 6, and an alkali metal gas introduction pipe 7. Alkali metal is heated by the sublimation oven 6, and the generated alkali metal gas is shot from t...

second concrete example

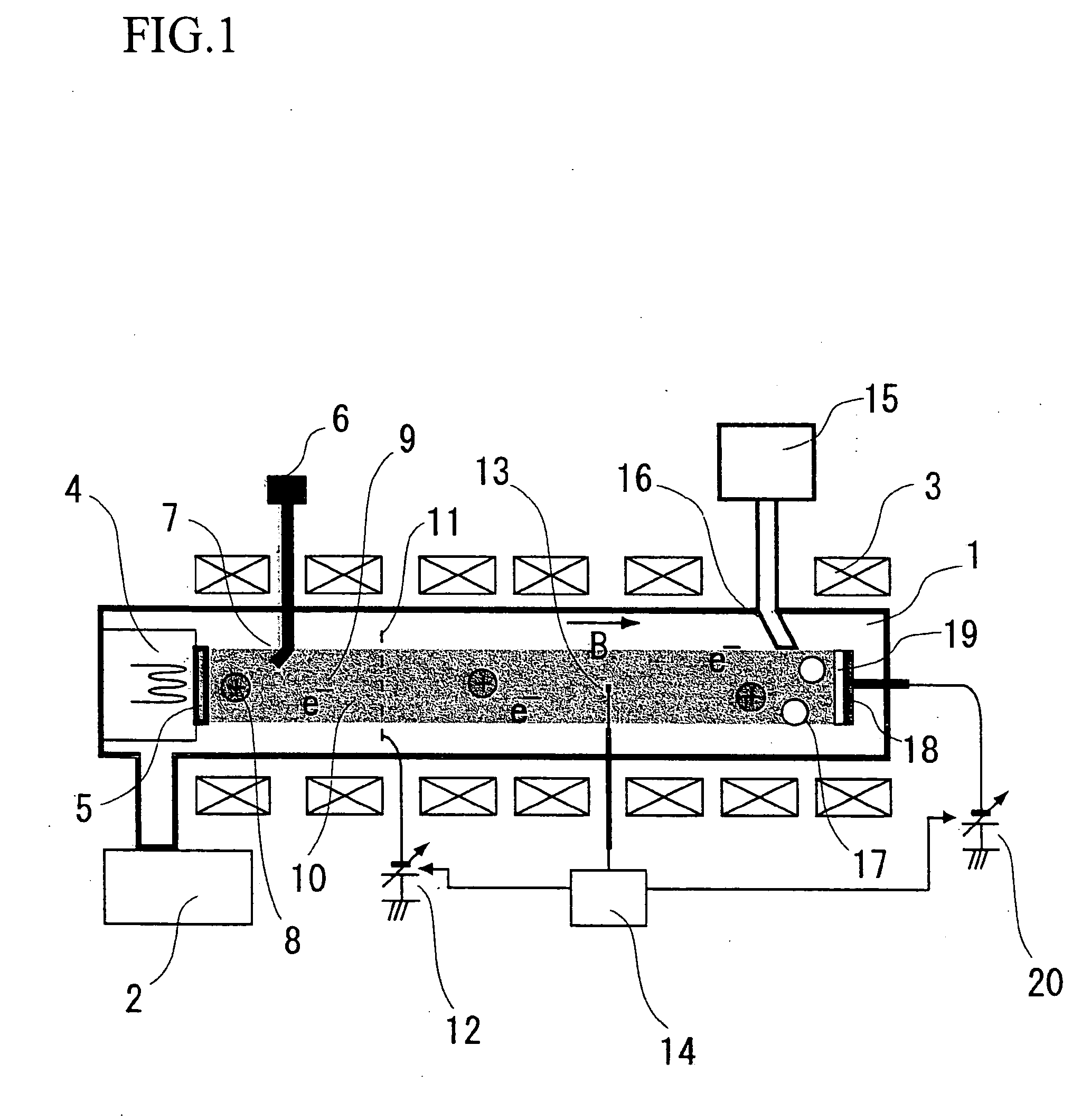

[0191]FIG. 2 is a cross-sectional view of a material film production apparatus according to a second concrete example of the present invention. The second concrete example is a containing-fullerene production apparatus configured to irradiate alkali metal ions and collision ions to fullerene to thereby produce alkali-metal-containing fullerene. Usable as alkali metal is Li, Na, K, or the like. Usable as collision ion is that of Cs, Fr, or the like.

[0192]The production apparatus is constituted of a vacuum vessel 51, an electromagnetic coil 53, alkali metal plasma-generation means, a plasma prove 64, fullerene vapor deposition means, a deposition-assistance substrate 69, and a bias voltage control power supply 71.

[0193]The vacuum vessel 51 is evacuated to a degree of vacuum of about 10−4 Pa by a vacuum pump 52. The plasma generation means is constituted of a heating filament 54, a hot plate 55, an alkali metal sublimation oven 56, an alkali metal gas introduction pipe 57, a collision ...

third concrete example

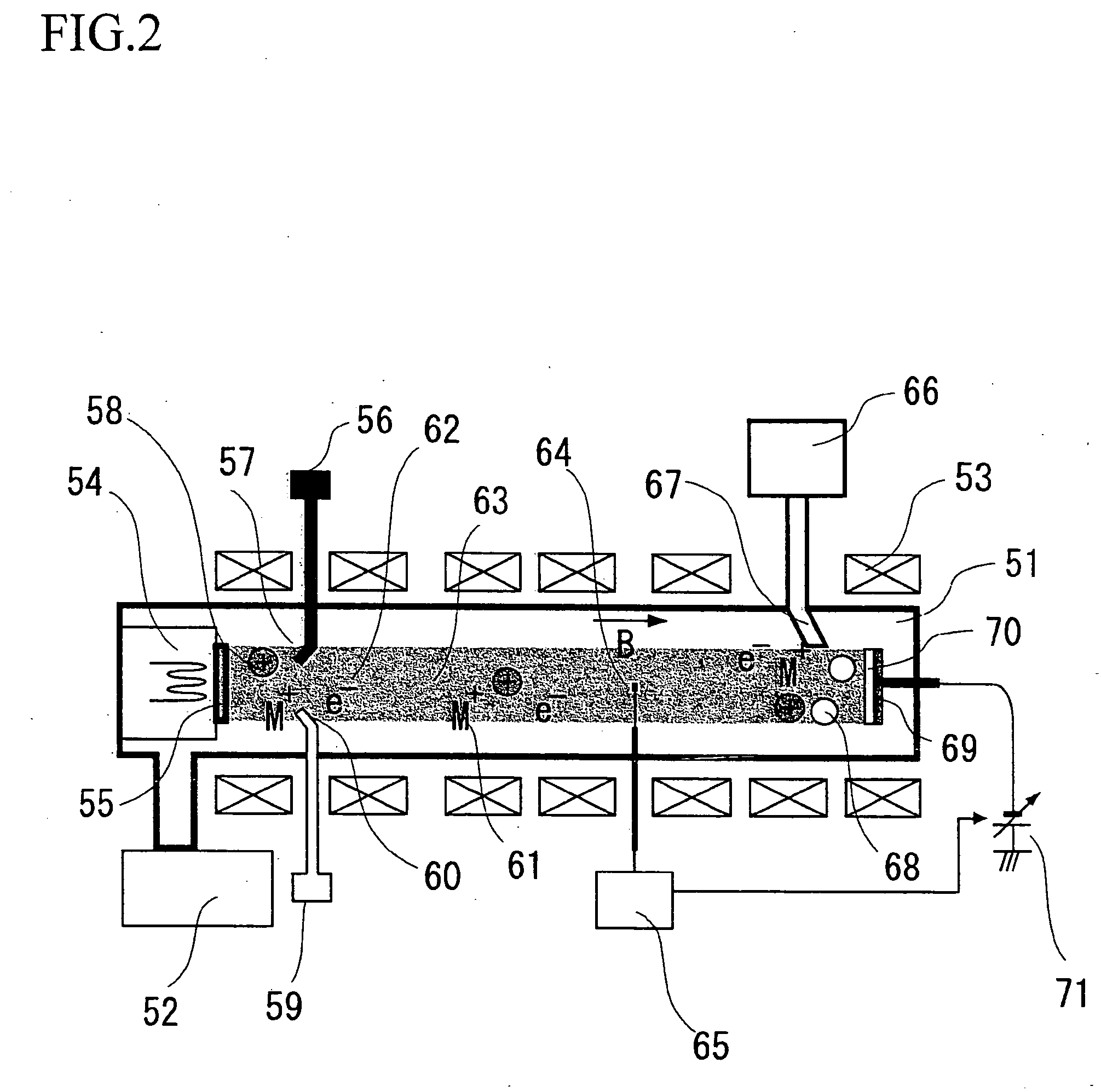

[0196]FIG. 3 is a cross-sectional view of a material film production apparatus according to a third concrete example of the present invention. The third concrete example is a containing-fullerene production apparatus configured to irradiate collision ions including alkali metal ions and C60+ to fullerene to thereby produce alkali-metal-containing fullerene. Usable as alkali metal ion is Li+, Na+, K+, or the like.

[0197]The production apparatus is constituted of a vacuum vessel 81, an electromagnetic coil 83, alkali metal plasma generation means, a grid electrode 91, fullerene ion generation means, a plasma prove 98, fullerene vapor deposition means, a deposition-assistance substrate 100, and a bias voltage control power supply 102.

[0198]The vacuum vessel 81 is evacuated to a degree of vacuum of about 10−4 Pa by a vacuum pump 82. The plasma generation means is constituted of a heating filament 84, a hot plate 85, an alkali metal sublimation oven 86, and an alkali metal gas introductio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| bias voltage | aaaaa | aaaaa |

| acceleration energies | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com