Laboratory plate thermal vault

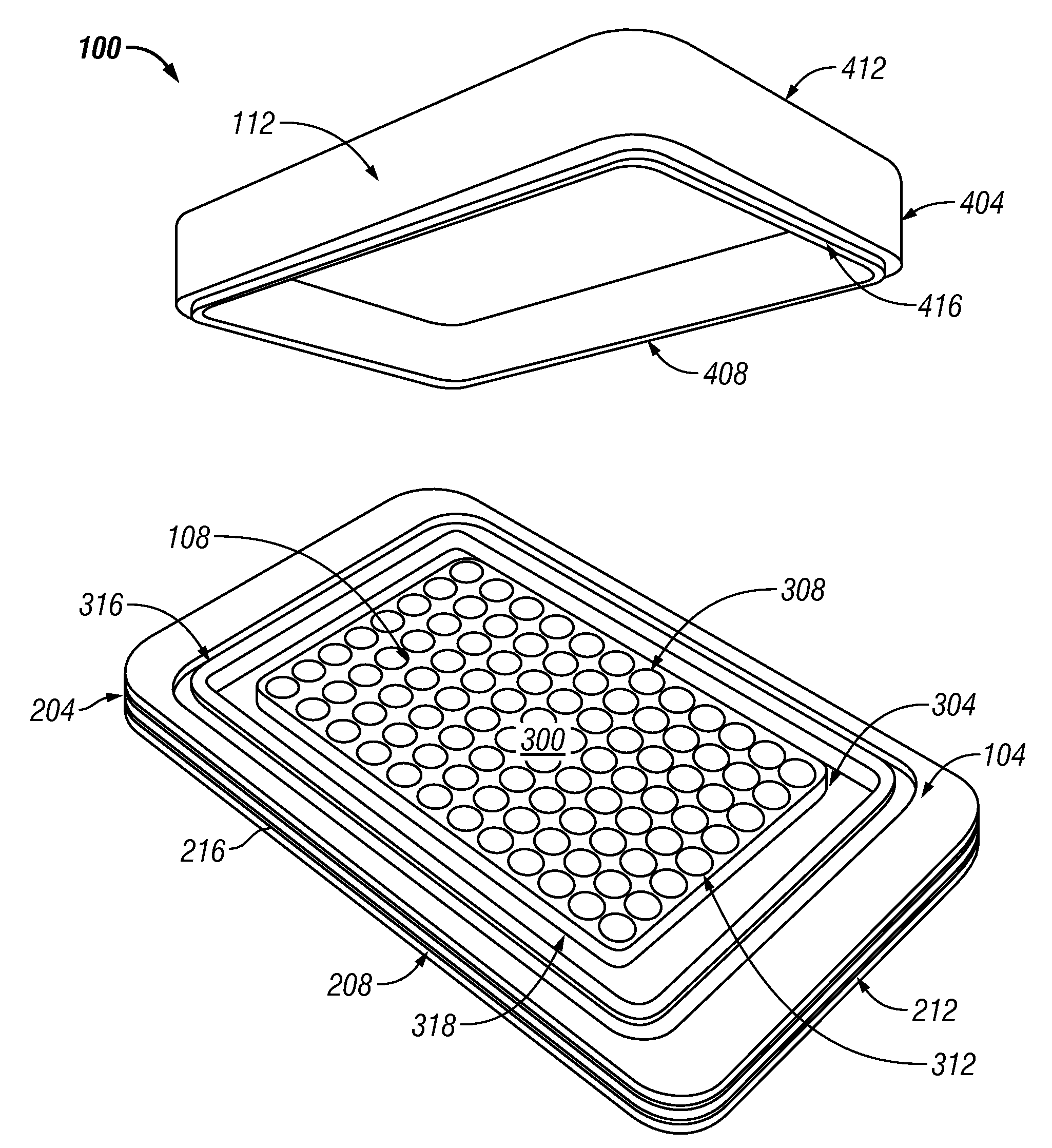

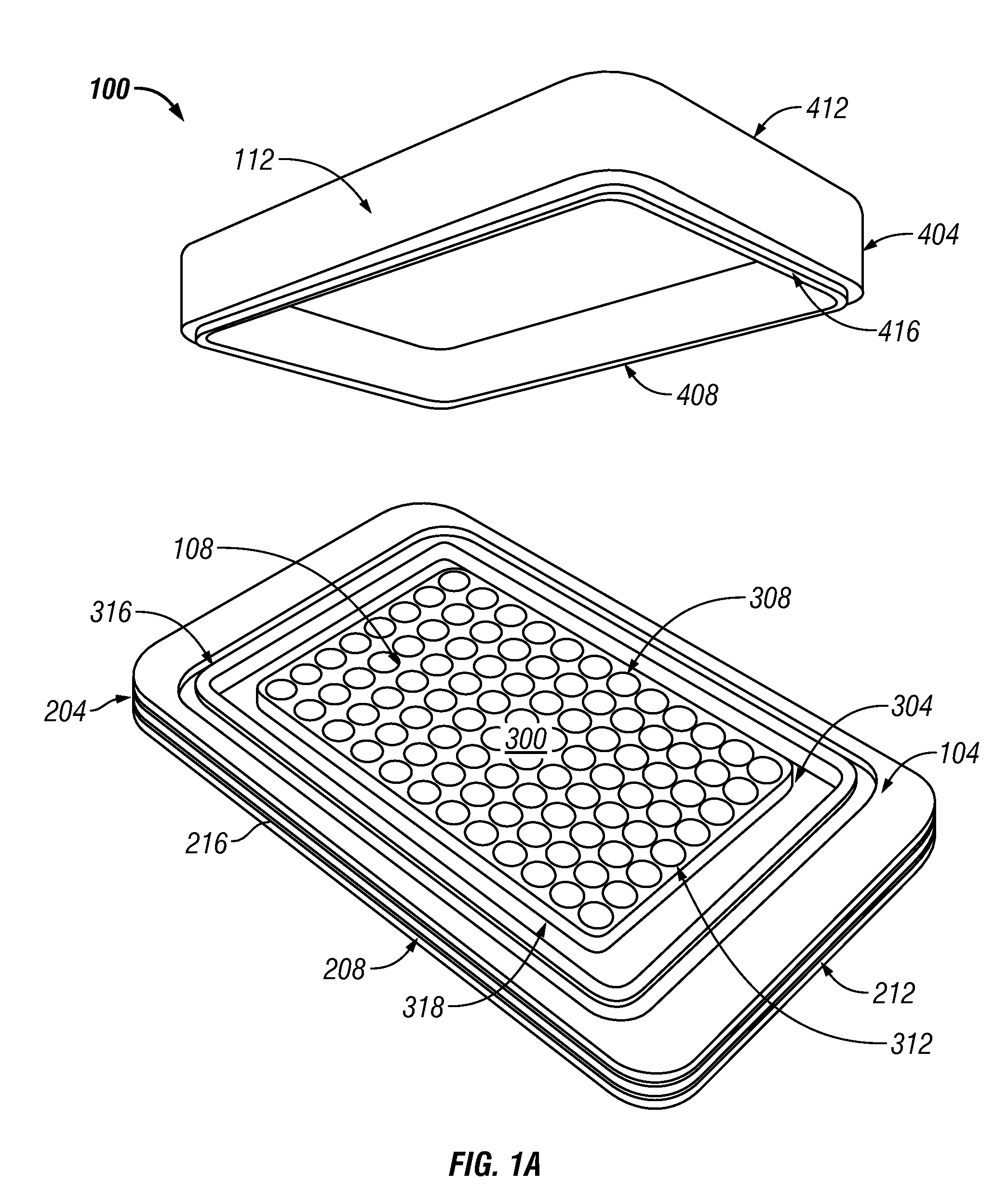

a laboratory plate and thermal vault technology, applied in the field of temperature transfer devices, can solve the problems of difficult temperature control, inability to work, and large apparatus requirements of conventional methods for controlling the temperature of laboratory plates, and achieve the effects of convenient portability and amenability to work, increased productivity, and greater consistency in the established physical sta

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0067]As an example, mammalian cell agar assays depend on rapid cooling of a cell suspension in molten agar so that the agar solidifies before the cells have a time to settle. In this particular application, the temperature transfer device is cooled to a desired temperature and the laboratory plate is placed on top of the stage such that the top surface of the stage comes in direct contact with the bottom of individual wells of the laboratory plate. This allows the contents of the individual wells to be cooled such that the agar solidifies before the cells have a time to settle.

[0068]Typically, the temperature transfer device of the invention is placed on ice, dry ice, liquid nitrogen or any heating or cooling device until the temperature of the temperature transfer device has reached the approximate temperature of the cooling or heating medium. The temperature transfer device can be left in contact with the cooling or heating medium or placed on a thermally insulating surface such ...

example 2

[0069]Reduction of Edge Effects in Cell Culture

[0070]A thermal vault with the sterile culture plate and plate cover seated in place would be placed into an incubator and allowed to equilibrate with the interior temperature. During this interval, cultured cells would be removed from their primary culture vessel by use of trypsin solution, transferred to a centrifuge tube, concentrated by centrifugation, and re-suspended in warm growth medium. The thermal vault with culture plate would be retrieved from the incubator and the cells to be cultured would be quickly dispensed to the appropriate wells. The plate cover would be replaced and the thermal vault encasement be placed into position. The assembly would be returned to the incubator and allowed to remain undisturbed until the cells have attached or until any other experimental way point. Due to the thermally conductive property of the stage, this method / procedure allows the culture plate to maintain a uniform well temperature across...

example 3

[0071]Reduction of Edge Effects in ELISA Assays

[0072]For reduction of edge effects in an ELISA assay, a 96-well flat bottom plate would be placed onto a thermal vault base either in a stand-alone configuration or in thermal contact with a temperature-regulation device. A standard ELISA assay would be assembled into the wells of the 96-well plate, and the plate cover replaced or the plate sealed using commonly available adhesive closure seals. The thermal vault encasement would be placed over the 96-well plate and seated into the base groove. A standard reaction time would be allowed to pass while the plate is either allowed to remain still or agitated by a common shaking device. The ELISA assay would then be completed by application of the appropriate wash steps and colorimetric reaction while the plate remains in contact with the vault base. Due to the thermally conductive property of the stage, a uniform well temperature would be maintained across the plate thereby reducing or eli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com