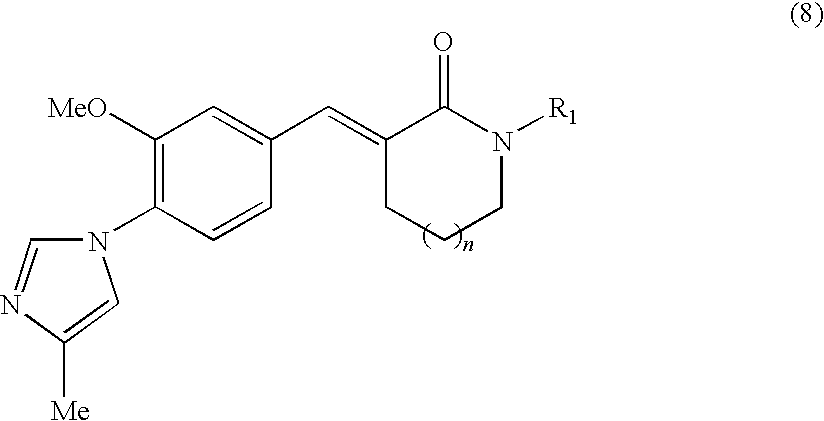

Process for production of cinnamide derivative

a technology of cinnamide and derivative, which is applied in the direction of group 5/15 element organic compounds, organic chemistry, drug compositions, etc., can solve the problem that the process of producing such compounds has not been known

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

reference example 1

Synthesis of 3-methoxy-4-(4-methyl-1H-imidazol-1-yl)benzaldehyde

[0288]

1) Synthesis of 3-methoxy-4-nitrobenzoic Acid Methyl Ester

[0289]Methyl iodide (463 g) was added dropwise to a mixture of 3-hydroxy-4-nitrobenzoic acid (199 g) and potassium carbonate (450 g) in DMF (1 L) at room temperature. The reaction solution was stirred at room temperature overnight and then methyl iodide (230 g) was added to the reaction solution. The reaction solution was further stirred at room temperature for six hours. The reaction solution was added to ice water and the precipitated solid was collected by filtration. The resulting solid was dried at 50° C. overnight to provide 178 g of the title compound. The property values corresponded to the reported values (CAS #5081-37-8).

2) Synthesis of 4-amino-3-methoxybenzoic Acid Methyl Ester

[0290]10% palladium-carbon (containing 50% water, 15 g) was added to a solution of 3-methoxy-4-nitrobenzoic acid methyl ester (150 g) in methanol (600 mL) and THF (300 mL) ...

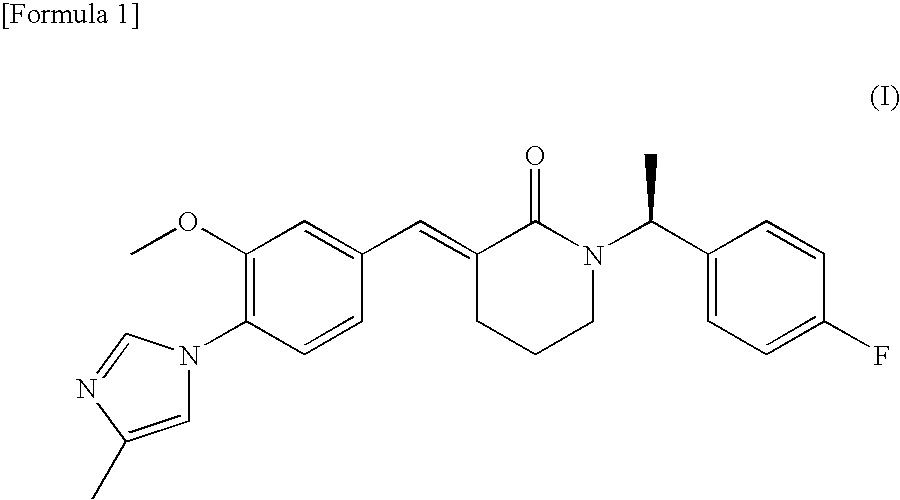

example 1

Synthesis of 1-[1-(4-fluorophenyl)ethyl]-3-{hydroxy[3-methoxy-4-(4-methylimidazol-1-yl)phenyl]methyl}piperidin-2-one

[0299]

[0300]A mixed solution of toluene (86 mL) and tetrahydrofuran (5.8 mL) containing diisopropylamine (10.1 mL, 71 mol, 1.58 equivalents) was cooled in a dry ice bath in a nitrogen atmosphere. n-Butyllithium (2.67 M solution in cyclohexane, 25.4 mL, 68 mmol, 1.5 equivalents) was added dropwise to the diisopropylamine solution at −20° C. After completion of the dropwise addition, the reaction solution was cooled to −70° C. or less and stirred for 30 minutes. Then, a solution of 1-[1-(4-fluorophenyl)ethyl]piperidin-2-one (10 g, 45.2 mol) in toluene (50 mL) was added dropwise to the reaction mixture over 30 minutes. A solution of 3-methoxy-4-(4-methylimidazol-1-yl)benzaldehyde (9.75 g, 45.1 mmol, 1.0 equivalents) in tetrahydrofuran (120 mL) was added dropwise to the reaction mixture over 30 minutes. After completion of the dropwise addition, the temperature of the cool...

example 2

Synthesis of 3-{chloro-[3-methoxy-4-(4-methylimidazol-1-yl)phenyl]methyl}-1-(4-fluorobenzyl)piperidin-2-one

[0306]

[0307]A solution of 1-[1-(4-fluorophenyl)ethyl]-3-{hydroxy[3-methoxy-4-(4-methylimidazol-1-yl)phenyl]methyl}piperidin-2-one (19.1 g) in dimethoxyethane (70 mL) was added dropwise to a solution of thionyl chloride (4.58 mL, 62.7 mol, 2 equivalents) in dimethoxyethane (70 mL) in a nitrogen atmosphere at 10° C. to 23° C. over 10 minutes. The reaction solution was stirred at 20° C. for two hours and then cooled in an ice water bath and toluene (140 mL) was added to the reaction mixture. Subsequently, a 2 N sodium hydroxide solution (140 mL) was added to the reaction mixture. The reaction solution was transferred to a separating funnel and the aqueous layer was discarded. The organic layer was sequentially washed with 5% saline (66 mL×2) and water (5 mL) and dried over anhydrous magnesium sulfate. The solvent was concentrated under reduced pressure to provide 22.1 g of a crude...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com