Electroactivated film with immobilized peroxide activating catalyst

a technology of activating catalyst and electroactivation film, which is applied in the direction of physical/chemical process catalyst, organic compound/hydride/coordination complex catalyst, non-metal conductor, etc., can solve the problems of mass contamination and danger to living subjects, and achieve the effect of facilitating the production of peroxid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0116]This example illustrates the formation of a carbon electrode on a substrate.

[0117]Carbon layers that can serve as an electrode for the present films can be applied by screen printing of conductive carbon ink. Examples of suitable inks include XM-740 flexible carbon ink available from Conductive Compounds, Londonderry, N.H., or Electrodag®PF407C carbon ink from Acheson Colloids Company, Port Huron, Mich.

[0118]The ink is screen printed either directly onto the surface of a substrate, or onto a pre-coating that has been applied to the substrate, or onto the surface of a cured gel layer. The ink is screen printed through a 196-mesh screen and then dried in a 100° C. oven for 10-30 minutes.

[0119]An electrode lead can then be attached to the carbon layer for connection to a source of electrical potential.

Carbon Cloth and Carbon Paper:

[0120]Carbon cloth “A” and “D” available from E-Tek Division, BASF Fuel Cell, Inc., Somerset, N.J., and carbon paper TGP-H-060 available...

example 2

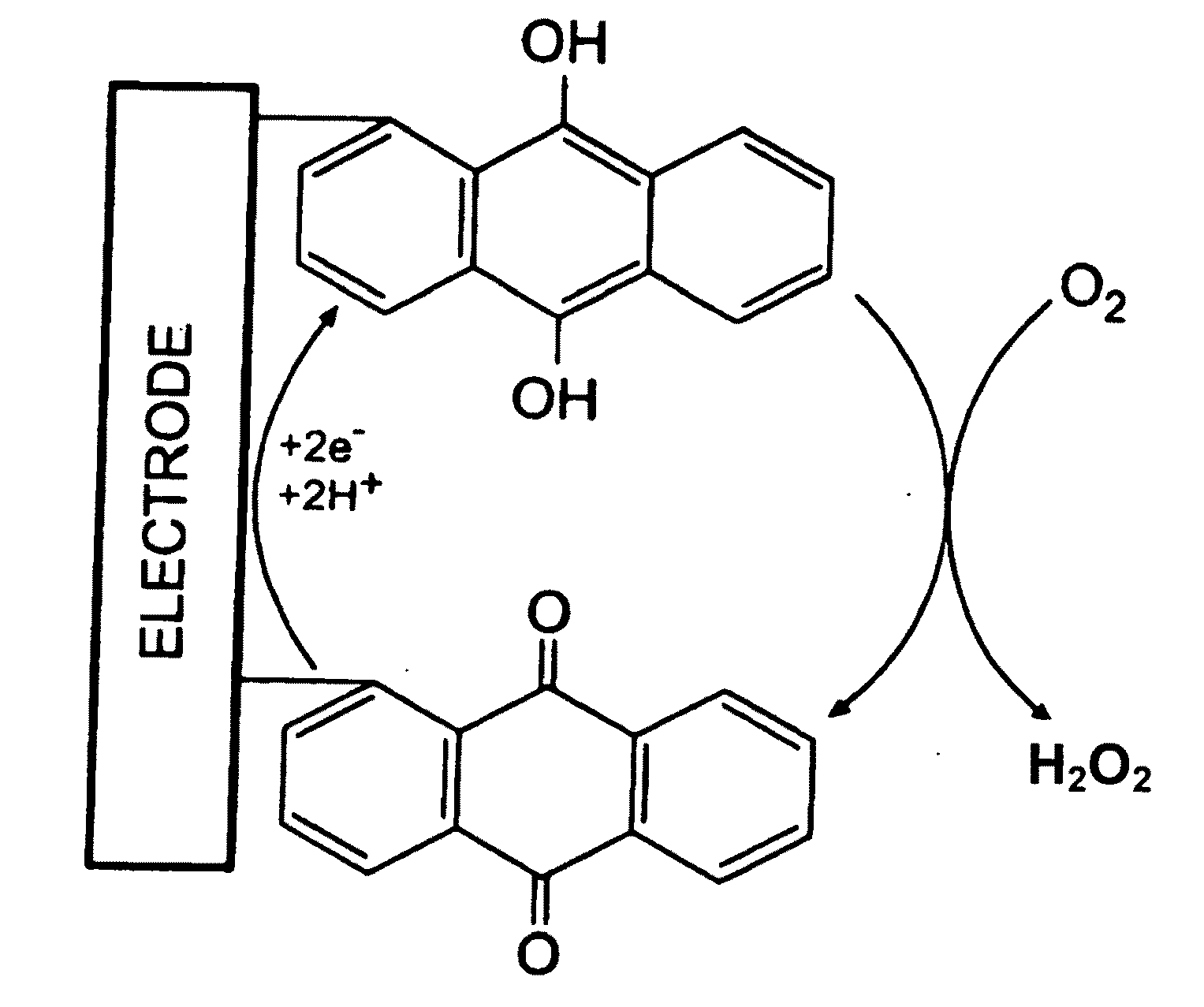

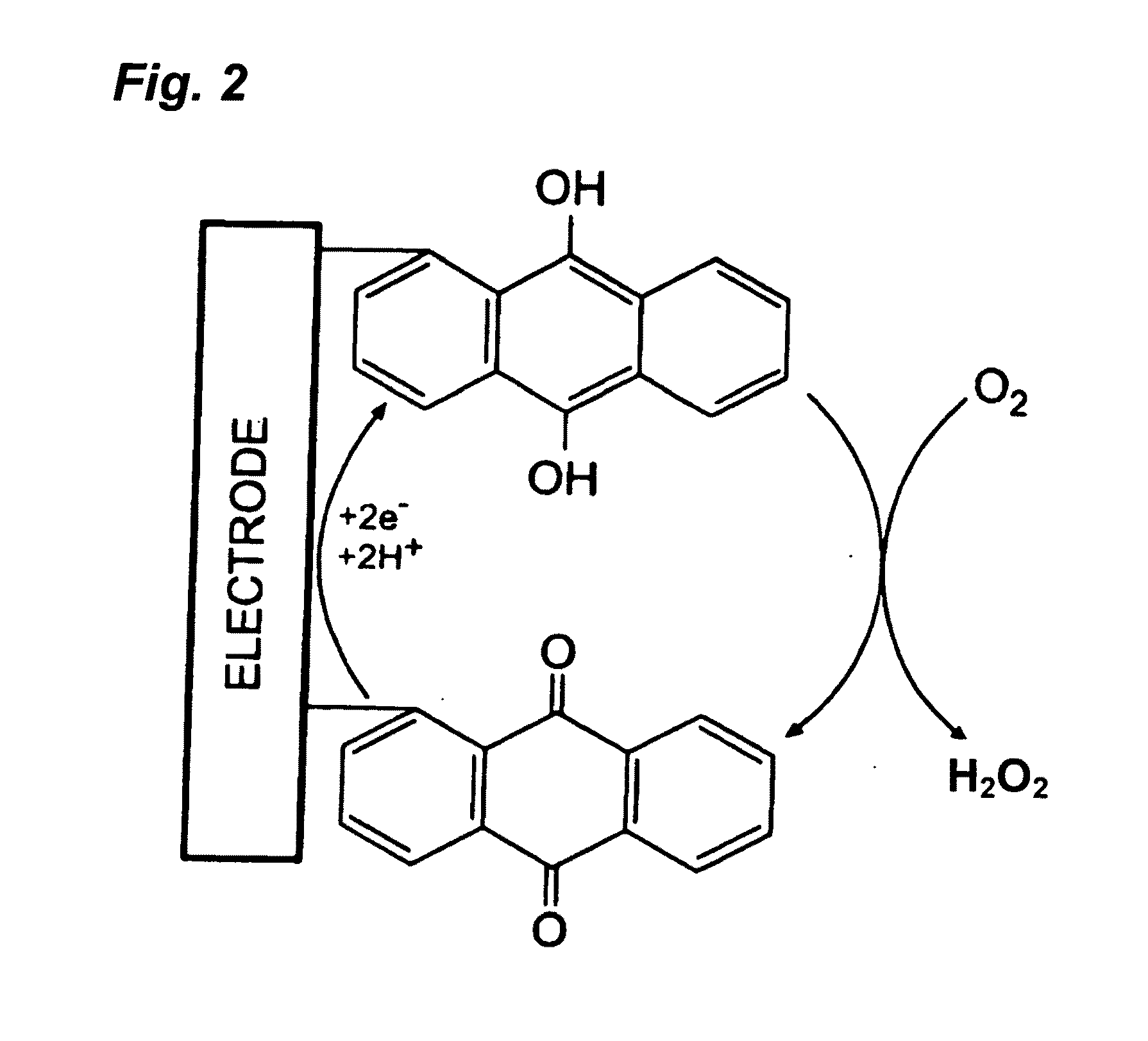

[0122]This example illustrates the deposition of a quinone coating onto a carbon electrode to form a (non-covalently bound) coated electrode.

Ethanol Solution Method:

[0123]Carbon electrode material was contacted at room temperature with 10% Nitric acid for 2 to 4 hours, then washed with water, dried and contacted at room temperature with 1M NaOH for another 2 to 4 hours, then washed with water and dried.

[0124]A solution was prepared that contained the desired quinone in ethanol. By way of example, although different concentrations of the quinone could be used, solutions of about 0.01M-1M, or about 0.01-0.05M quinone in ethanol, or from about 0.1% to about 10% by weight of the quinone, were found to be useful.

[0125]The treated carbon materials were placed in the quinone solution for about 6 to 12 hours, taken out, dried in air and then washed three times with DI water, and immersed in DI water for 12 hours, then taken out and dried. The carbon materials coated with quinone were then r...

example 3

[0128]This example illustrates the electrochemical modification of carbon fiber electrodes by covalently-grafted anthraquinone

[0129]Carbon fiber electrodes were used as substrates (working electrodes) in the 3-electrode configuration (Reference Electrode RE: SCE; Counter Electrode CE: Carbon Fiber Electrode). These electrodes are made as a bunch of 5 strands taped together at one end using Aluminum tape and immersed in solution to 3 cm depth at the other end (single strands are pulled out of a twill weave fabric obtained from Aerospace Composites, ACP Composites, Livermore, Calif.).

[0130]The electrolytic solution consists of 0.01M (10 mM) Anthraquinone Diazonium chloride (Fast red AL salt) and 0.1M Tetrabutyl Ammonium Tetrafluoroborate in Acetonitrile medium. Carbon Fiber electrodes were used as substrates (Working Electrode—WE) in a 3-electrode configuration with RE: SCE and CE: C Fiber electrodes. A schematic representation of the procedure is shown in FIG. 3.

[0131]Quinone was dep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pH | aaaaa | aaaaa |

| pH | aaaaa | aaaaa |

| voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com