Fatty acid metal salt for forming ultrafine metal particles

a metal salt and fatty acid technology, applied in the field of fatty acid metal salts, can solve problems such as difficulty in perfectly executing reactions, and achieve the effects of excellent performance, excellent deodorizing performance or voc-adsorption performance, and effective adsorption of smelling components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

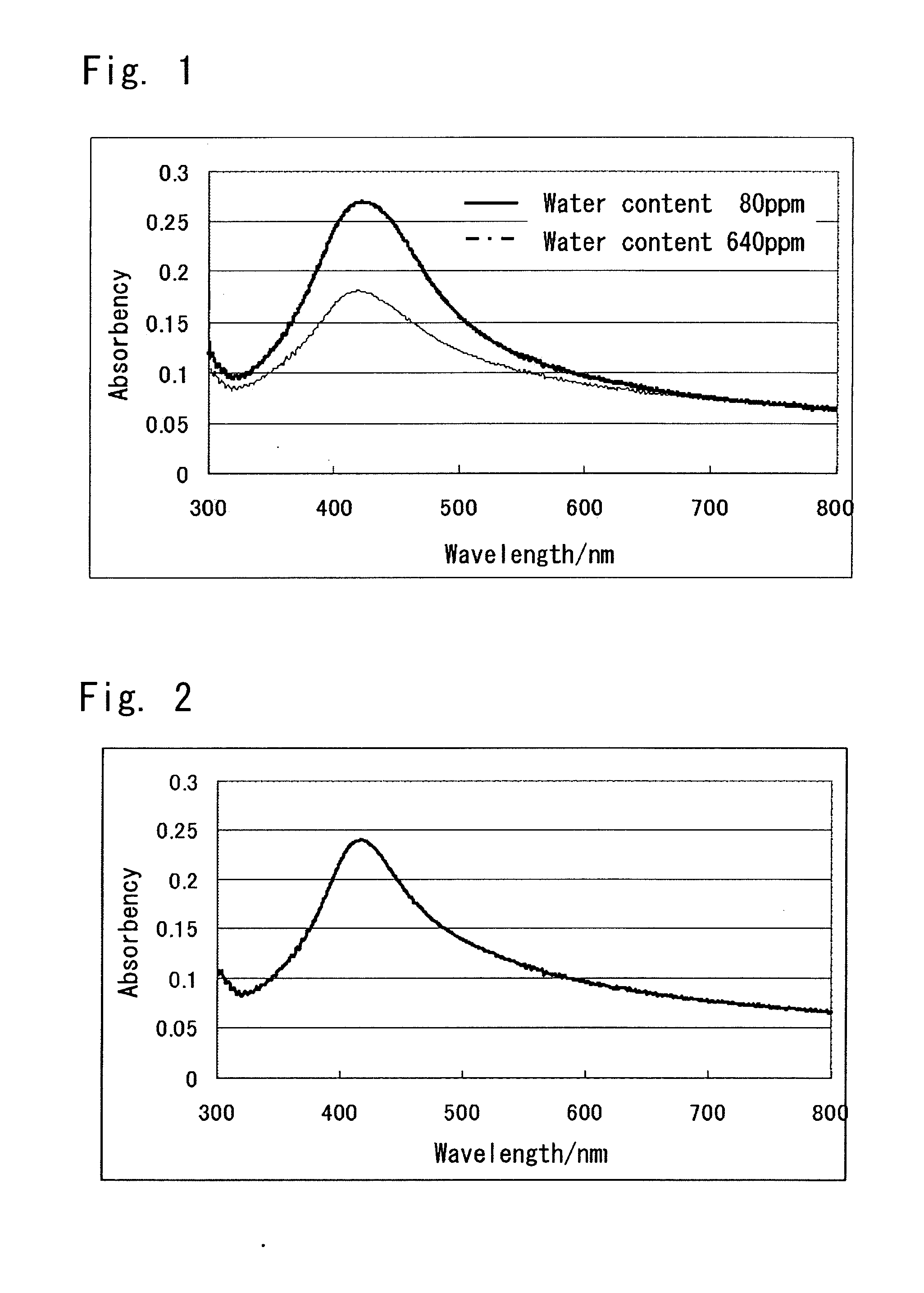

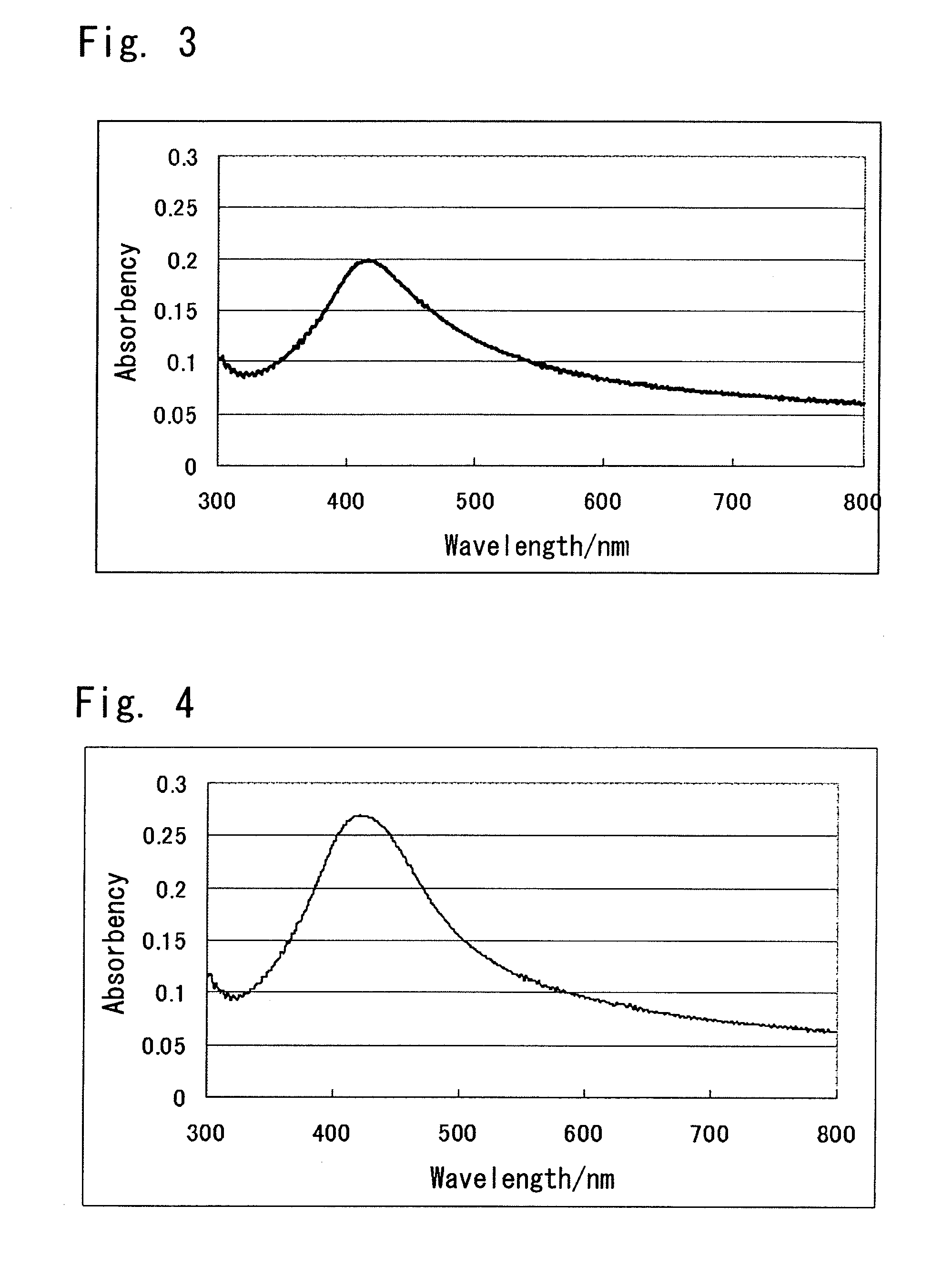

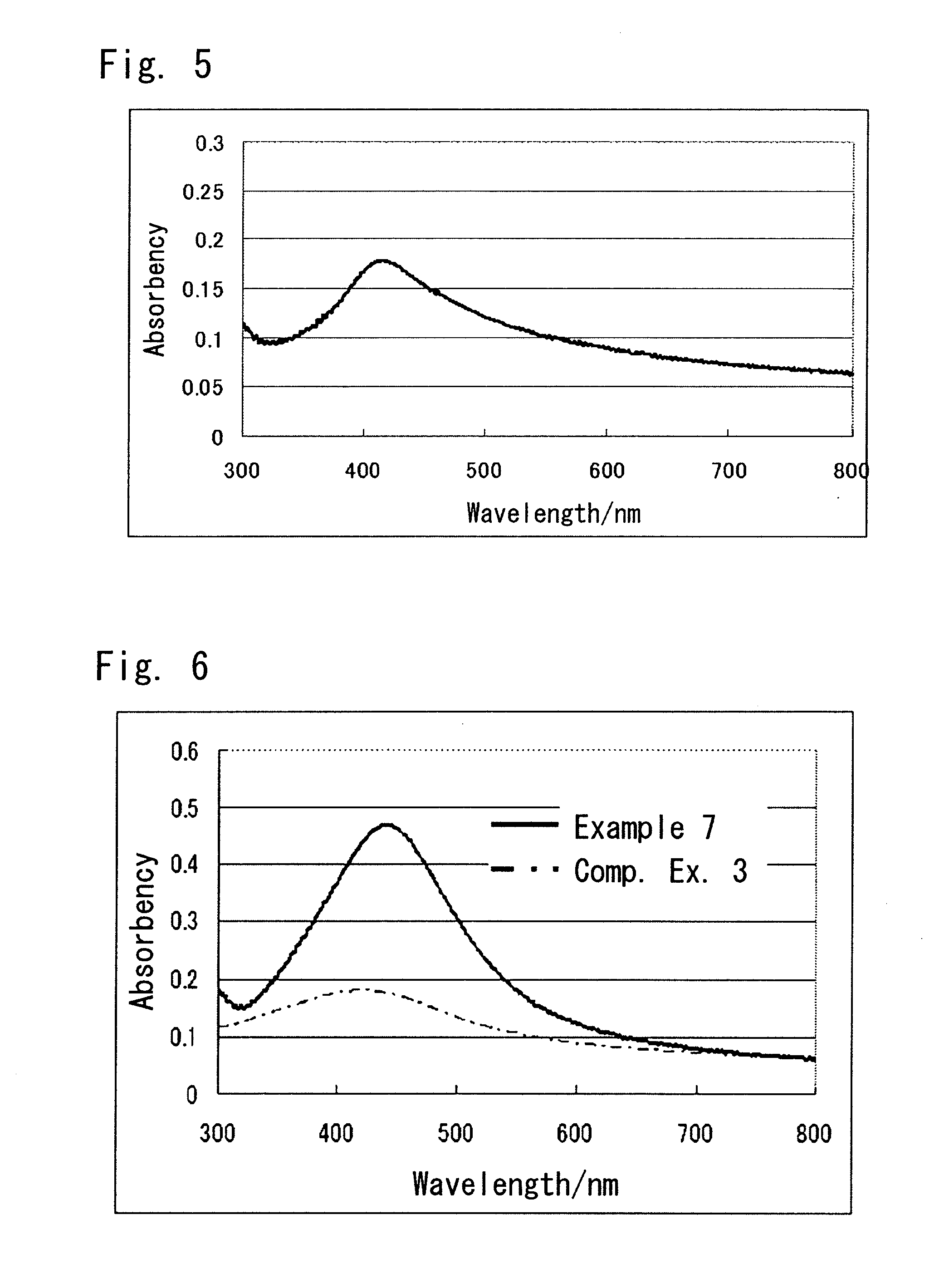

example 1

[0110]There were prepared a solution (a) by dissolving 76.6 g of sodium stearate in 3000 g of water maintained at 90° C. and a solution (b) by dissolving 40.3 g of silver nitrate in 600 g of water. Next, the solution (b) was thrown into the solution (a) while stirring the solution (a). After having stirred for 15 minutes from the throwing, washing was conducted to a sufficient degree by using deionized water while effecting the solid-liquid separation by filtration by means of suction. By using a hot-air drier (SPH-101 manufactured by Tabai-Espec Co.), the obtained solid was dried at 100° C. for 24 hours to obtain a silver stearate having a water content of 80 ppm. Next, by using the silver stearate, a film was prepared containing the ultrafine metal particles. The obtained film was subjected to the above deodorizing test to calculate the deodorizing ratio.

example 2

[0111]A silver stearate was prepared in the same manner as in Example 1 but conducting the hot-air drying at 100° C. for 20 hours so that the water content was 125 ppm. A film containing ultrafine metal particles was prepared and was subjected to the deodorizing test to calculate the deodorizing ratio.

example 3

[0112]A silver stearate was prepared in the same manner as in Example 1 but conducting the hot-air drying at 100° C. for 18 hours so that the water content was 184 ppm. A film containing ultrafine metal particles was prepared and was subjected to the deodorizing test to calculate the deodorizing ratio.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Water content | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com