Method for making a thin film having a metallic pattern layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

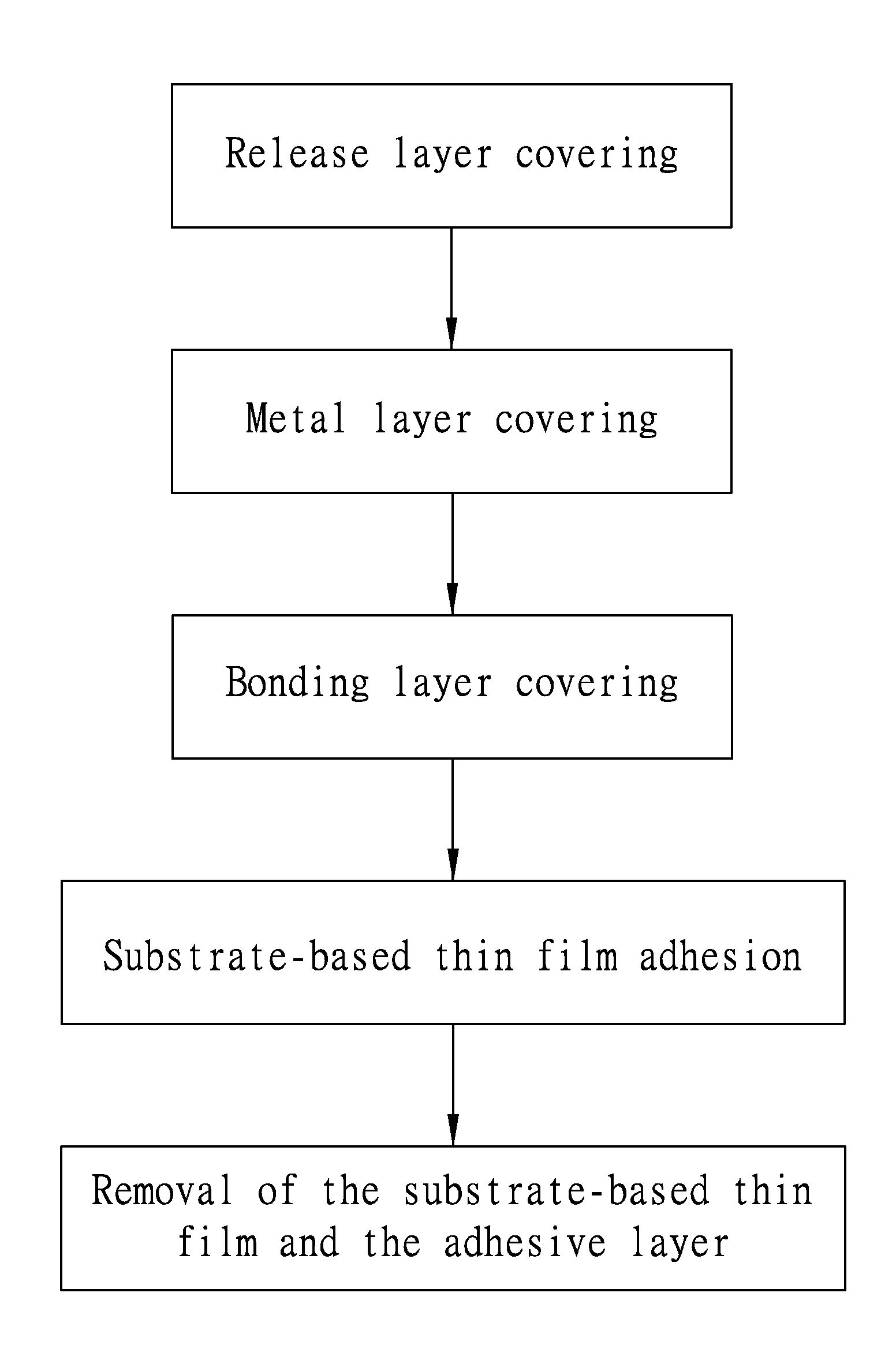

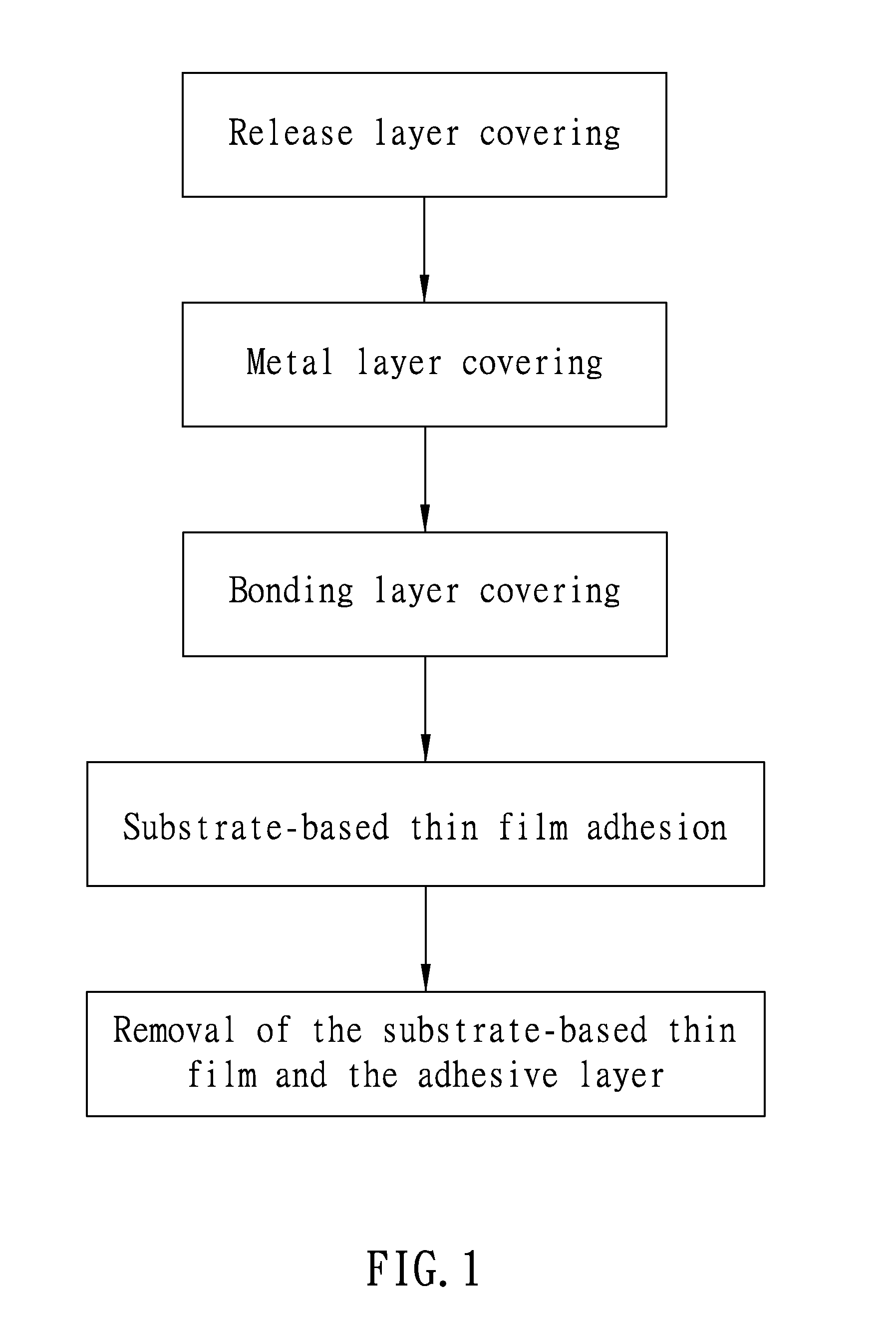

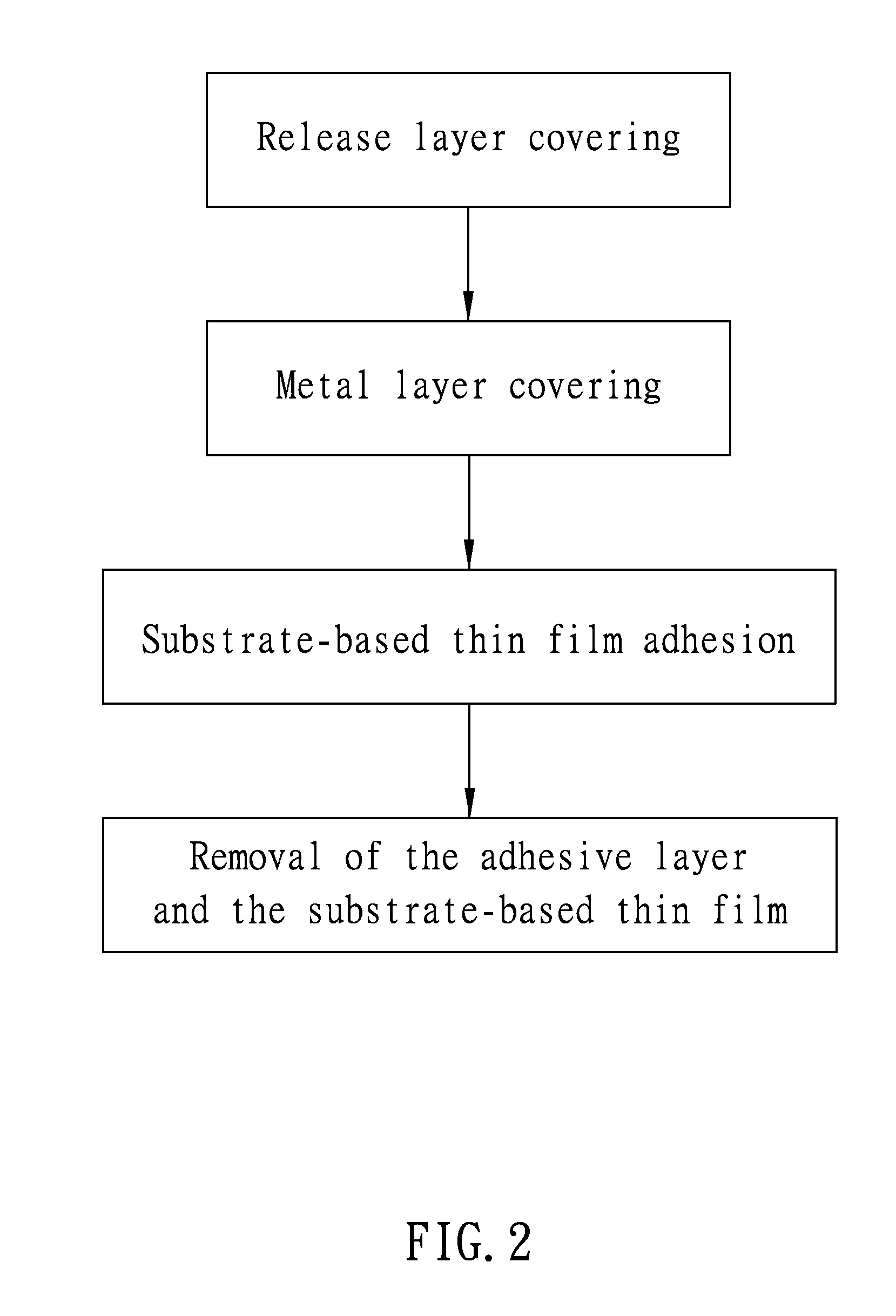

[0022]Referring to FIGS. 1 and 2, a method for making a thin film having a metallic pattern layer in accordance with the present invention includes the following steps:[0023](1) Release layer covering: As shown in FIGS. 3 and 4, cover the surface of a thin film substrate 1 with a release layer 2 by means of spray-painting, coating or printing technique, leaving a blank area 21 of a predetermined pattern (such as lines, letters, symbols, numerals, and so on) in the release layer 2. The thin film substrate 1 can be a paper film, a plastic film or an induction plastic film made from a high molecular chemical reaction engineering material of thermosetting resin and / or thermoplastic resin, such as PU (polyurethane), UP (unsaturated polyester), PS (polystyrene) and other high molecular polymers. The release layer 2 is a transparent or a colored layer prepared from a hydrophilic or lipophilic resin material such as polyvinyl alcohol or polyvinyl acetate, etc.[0024](2) Metal layer covering:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Metallic bond | aaaaa | aaaaa |

| Transparency | aaaaa | aaaaa |

| Hydrophilicity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com