Recovery of Hydrocarbon From Aqueous Streams

a hydrocarbon and aqueous technology, applied in the field of hydrocarbon extraction, can solve the problems of high energy intensity required for solvent recovery, difficult solvent recovery from the solids produced in the previously described process, and inability to be adopted in a commercial application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

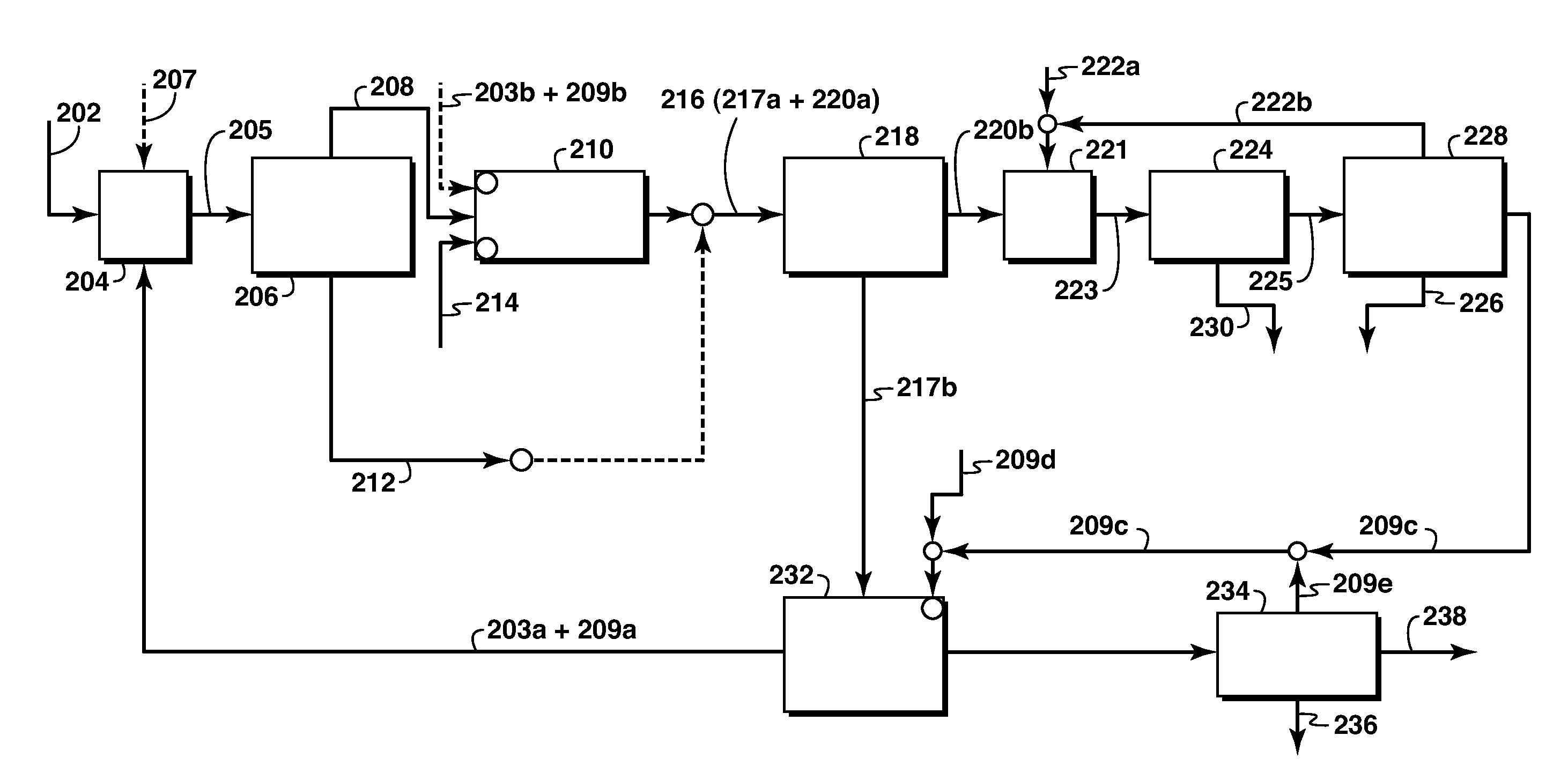

Image

Examples

example 1

[0201]Approximately 500 g of low grade oil sands (comprising 22 wt % fines) was mixed with 300 g cyclohexane as a first solvent (loaded with bitumen up to 40 wt %) using an impeller in a mixing vessel at 30° C. Sand grains greater than 1 mm were removed by screening. The remaining slurry was passed into an agglomerator where 30 ml of water was added. Agglomerates of sizes ranging from 0.1 mm to 1 cm were formed. The agglomerated slurry was allowed to settle for 30 minutes and a first supernatant was collected for water and solids content analysis. Solids content determined by ashing ranged between 5,000-20,000 ppm on a dry bitumen basis for this first supernatant while water content by Karl Fischer analysis was generally less than 1000 ppm. Portions of the first supernatant were mixed with normal pentane as a second solvent above the critical solvent to bitumen ratio to effect precipitation of asphaltene at 30° C. After settling for 30 minutes, a second supernatant was collected and...

example 2

[0202]In another experiment similar to the one described in Example 1, a mixture of 30% cyclohexane and 70% heptane, by volume, was used in agglomeration as the first solvent. For the first supernatant, solids content determined by ashing range between 5,000-10,000 ppm on a dry bitumen basis while water content by Karl Fischer analysis was generally less than 1,000 ppm. Portions of the first supernatant were mixed with normal pentane as a second solvent above the critical solvent to bitumen ratio to effect precipitation of asphaltene at room temperature. The solids and water content of the resulting second supernatant was determined to be less than 400 ppm and 200 ppm on a dry bitumen basis after 30 minutes of settling.

example 3

[0203]In another experiment similar to the one described in Example 1, normal heptane loaded with 40% bitumen was used as extraction solvent (the first solvent). Solids content of the first supernatant was determined to be less than 400 ppm on a dry bitumen basis after 30 minutes of settling. Water content was less than 200 ppm. The resulting product, having less than 400 ppm of filterable solids was a high grade bitumen product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ratio | aaaaa | aaaaa |

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com