Asparaginase from basidiomycetes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

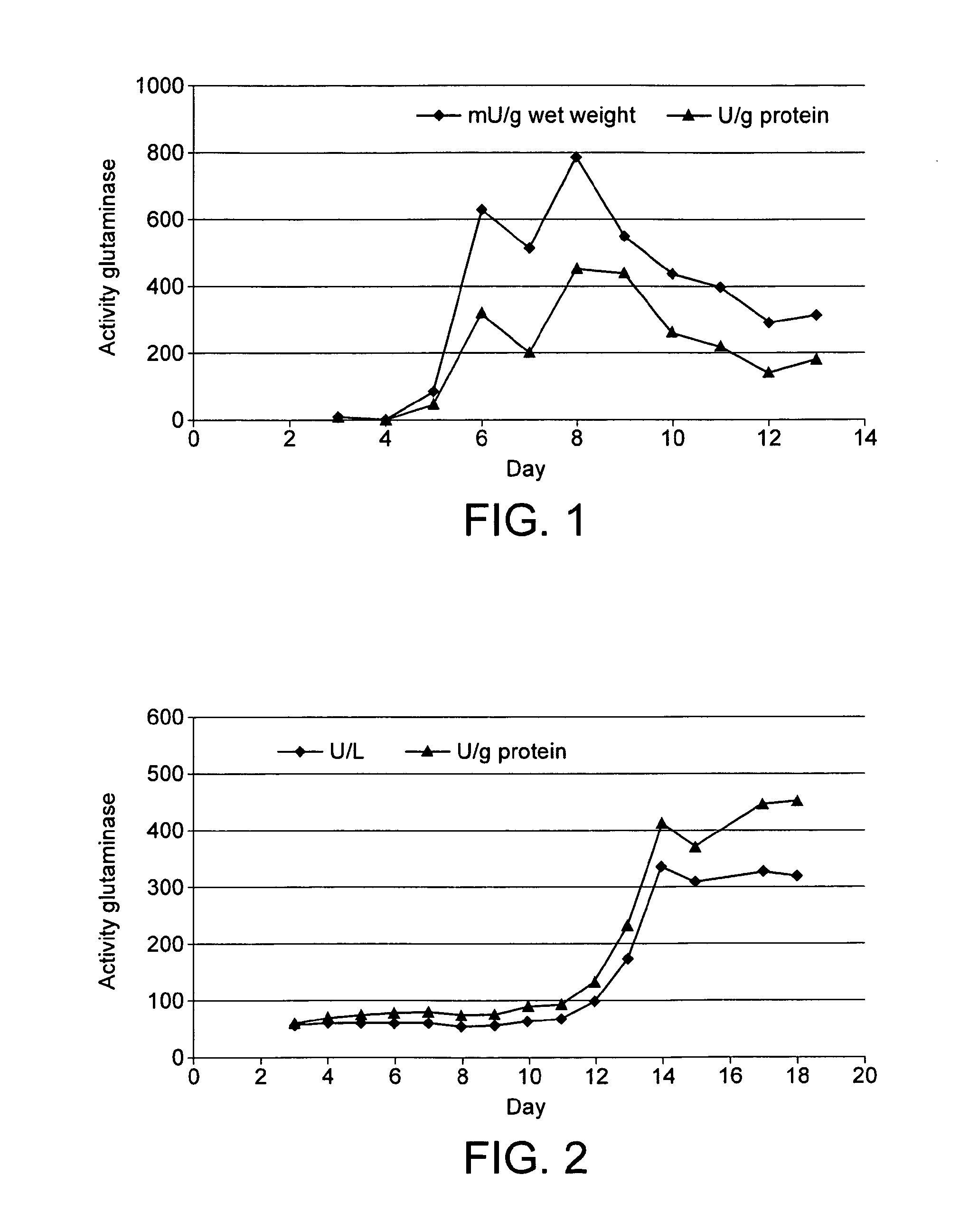

Cultivation of Flammulina velutipes

[0119]All media and equipment were autoclaved prior to use and standard sterile techniques were applied throughout the procedure. Flammulina velutipes was maintained on standard agar plates (30.0 g L−1 glucose-monohydrate; 4.5 g L−1 asparagine-monohydrate; 1.5 g L−1 KH2PO4; 0.5 g L−1 MgSO4; 3.0 g L−1 yeast extract; 15.0 g L−1 agar agar; 1.0 mL L−1 trace metal solution containing 0.005 g L1 CuSO4.5H2O, 0.08 g L−1 FeCl3.6H2O, 0.09 g L−1 ZnSO4.7H2O, 0.03 g L−1 MnSO4H2O and 0.4 g L−1 EDTA. The pH of the medium was adjusted to pH 6 with 1 M NaOH prior to sterilisation. Precultures were prepared by homogenisation of a 10×10 mm agar plug with mycelium of Flammulina velutipes in 100 mL of sterile standard nutrition solution using an Ultra Turrax (Miccra D-9, Art, Müllheim, Germany). Submerged cultures were maintained at 24° C. and 150 rpm. After cultivation for 5 days, 50 ml preculture were transferred into 250 ml main culture medium consisting of minimal...

example 2

Enzyme Preparation from Flammulina velutipes

[0120]After 18 days of cultivation, the culture was filtrated and the extracellular enzyme-containing supernatant (200 mL) was reverse-foamed, the asparaginase and another protein being the only proteins left in the supernatant. The remaining liquid was concentrated using ultra-filtration (MWCO 10,000), and both proteins were separated via size exclusion chromatography at a Superose 6.

[0121]Most of the hydrolytic activity originally present was recovered indicating that this protocol yielded a useful enzyme concentrate through two steps only.

example 3

Hydrolysis of L-Asparagine Using Native Enzyme

[0122]100 μL of 10 mM asparagine in 0.1 M K2HPO4 / KH2PO4 buffer (pH 7.0) were preheated at 37° C. for 5 min. The reaction was started with the addition of 50 μL enzyme solution. After an incubation time of 20 min at 37° C. and 400 rpm in a thermoshaker, the assay was stopped by the addition of 20 μL TCA. A control experiment was carried out without substrate. The contents of aspartic acid were quantitatively measured with the HPLC after OPA-derivatisation, and the difference between sample and control was used to calculate then enzyme's activity.

[0123]The analytical evidence indicates a fast enzymatic hydrolysis of the substrate L-asparagine.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com