Olefin polymerization catalyst composition and olefin polymerization process using the same

a technology of olefin polymerization and composition, which is applied in the direction of catalyst activation/preparation, physical/chemical process, chemical/physical process, etc., can solve the problems of high production cost of conventional metallocene catalyst and difficulty in easily controlling the properties of olefin polymers, and achieves excellent commercial availability, simple process, and the effect of minimizing the time and process for producing catalys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

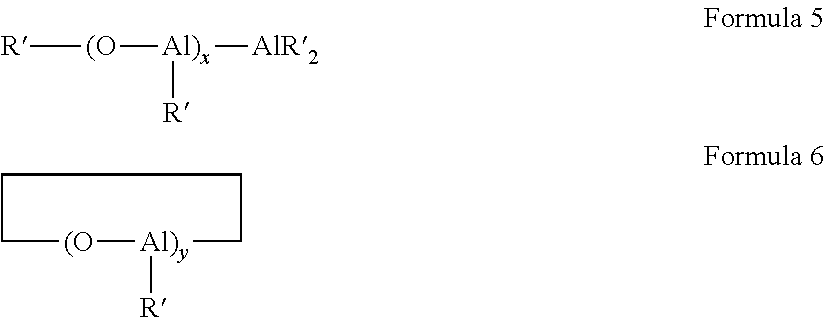

Method used

Image

Examples

example 1

Preparation of Catalyst and Solution Polymerization of Ethylene

[0034]In a 500 ml flask of nitrogen atmosphere, indenyl aluminium diethyl(Ind-AlEt2) 5.1 mg (0.018 mmol), bis(tetrahydroindenyl)zirconium dichloride 2.4 mg (Mw: 401, 0.006 mmol), zirconium chloride (ZrCl4) 1.4 mg (0.006 mmol) and methyl aluminoxane (MAO, Albemarle company, 10% toluene solution) 10 ml were mixed (Zr=6.0 μmol, Al / Zr mole ratio 2,500), and stirred at 60° C. for 30 minutes to obtain a catalyst solution.

[0035]A stainless autoclave reactor of 1 L having a jacket for supplying cooling water for controlling a polymerization temperature was purged with isobutane (one time) and ethylene (five times) at about 85° C. to remove impurities, and then cooled to room temperature. Dried hexane 300 ml and triisobutylaluminum (TIBA) as an impurity remover 1.0 mmol were added into the washed reactor at room temperature, and heated to a polymerization temperature of 70° C. The obtained catalyst solution was directly added int...

example 2

Preparation of Catalyst and Copolymerization of Ethylene / Hexene-1

[0036]In a 500 ml flask of nitrogen atmosphere, indenyl aluminium diethyl(Ind-AlEt2) 318 mg, bis(tetrahydroindenyl)zirconium dichloride 124 mg, zirconium chloride (ZrCl4) 69 mg and methyl aluminoxane (MAO, Albemarle company, 10% toluene solution) 50 ml were mixed, and stirred at 60° C. for 30 minutes to obtain a catalyst solution. 10 g of silica calcined at 220° C. was added to the produced catalyst solution, and ultrasonic wave was applied for 90 minutes, and the supernatant was discarded. The remaining solid particles were washed with hexane (1 time), and dried in vacuum to obtain a supported catalyst which was free-flowable solid powder.

[0037]A stainless autoclave reactor of 1 L having a jacket for supplying cooling water for controlling a polymerization temperature was purged with isobutane (one time) and ethylene (five times) at about 110° C. to remove impurities, and then cooled to 67° C. Isobutane 400 ml and tri...

example 3

Preparation of Catalyst and Copolymerization of Ethylene / Hexene-1

[0038]In a 500 ml flask of nitrogen atmosphere, indenyl lithium (Ind-Li) 75 mg, bis(tetrahydroindenyl)zirconium dichloride 124 mg, zirconium chloride (ZrCl4) 69 mg and methyl aluminoxane (MAO, Albemarle company, 10% toluene solution) 50 ml were mixed, and stirred at 60° C. for 90 minutes to obtain a catalyst solution. 10 g of silica calcined at 220° C. was added to the produced catalyst solution, and ultrasonic wave was applied for 90 minutes, and the supernatant was discarded. The remaining solid particles were washed with hexane (1 time), and dried in vacuum to obtain a supported catalyst of free-flowable solid powder. Except for using the catalyst 61 mg prepared in the above step, the polymerization was carried out for 3 hours in accordance with the polymerization method of Example 2 to obtain the polymer 327 g. The polymerization rate during 3 hours of the polymerization reaction was kept steady. The catalytic acti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| composition | aaaaa | aaaaa |

| valence | aaaaa | aaaaa |

| mole ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com