Cathodic protection system

a protection system and cathode technology, applied in the field of cathode protection system, can solve the problems of unfavorable application life expectancy, titanium has/had historical technical limitations on voltage, and platinised niobium was not cost competitive, etc., to achieve easy installation, increase the life expectancy of the system, and provide a level of flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

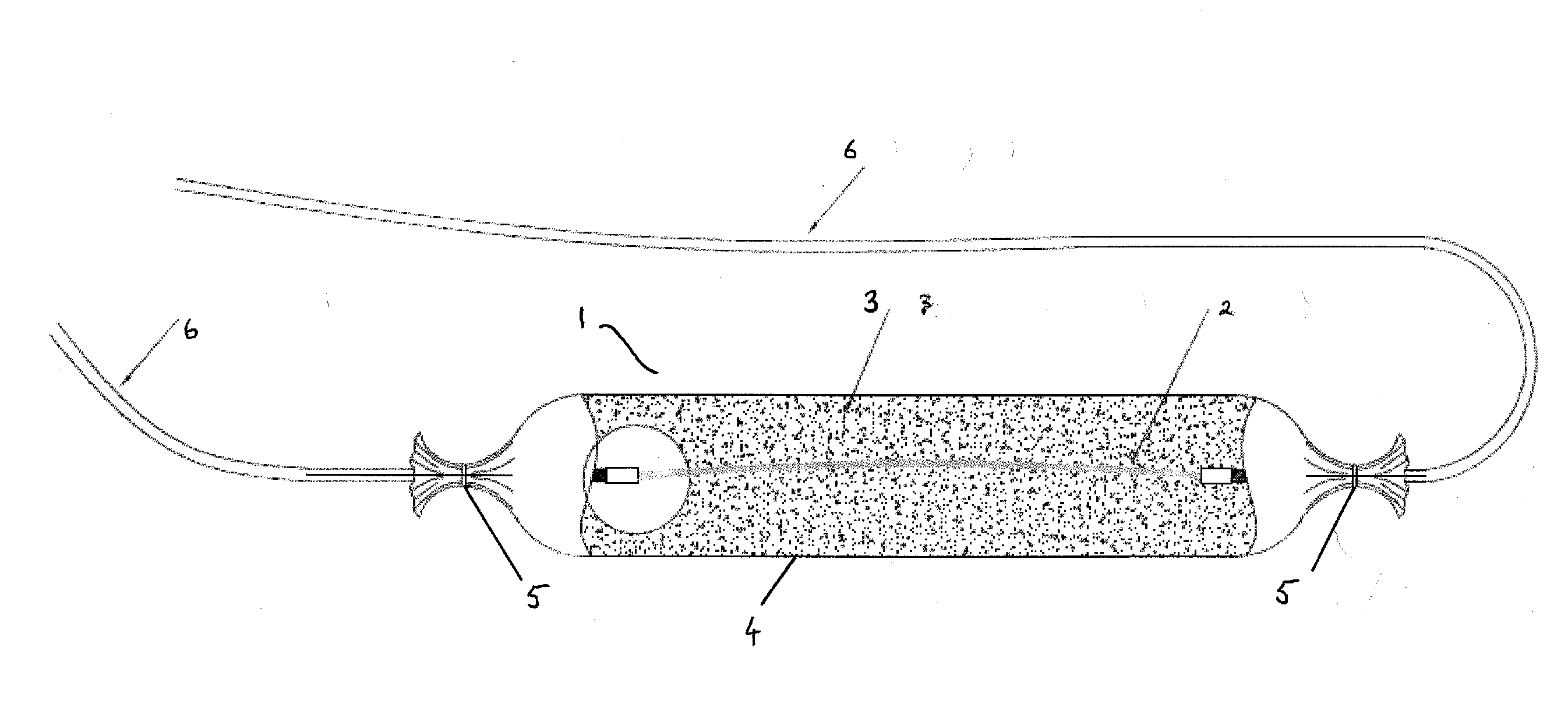

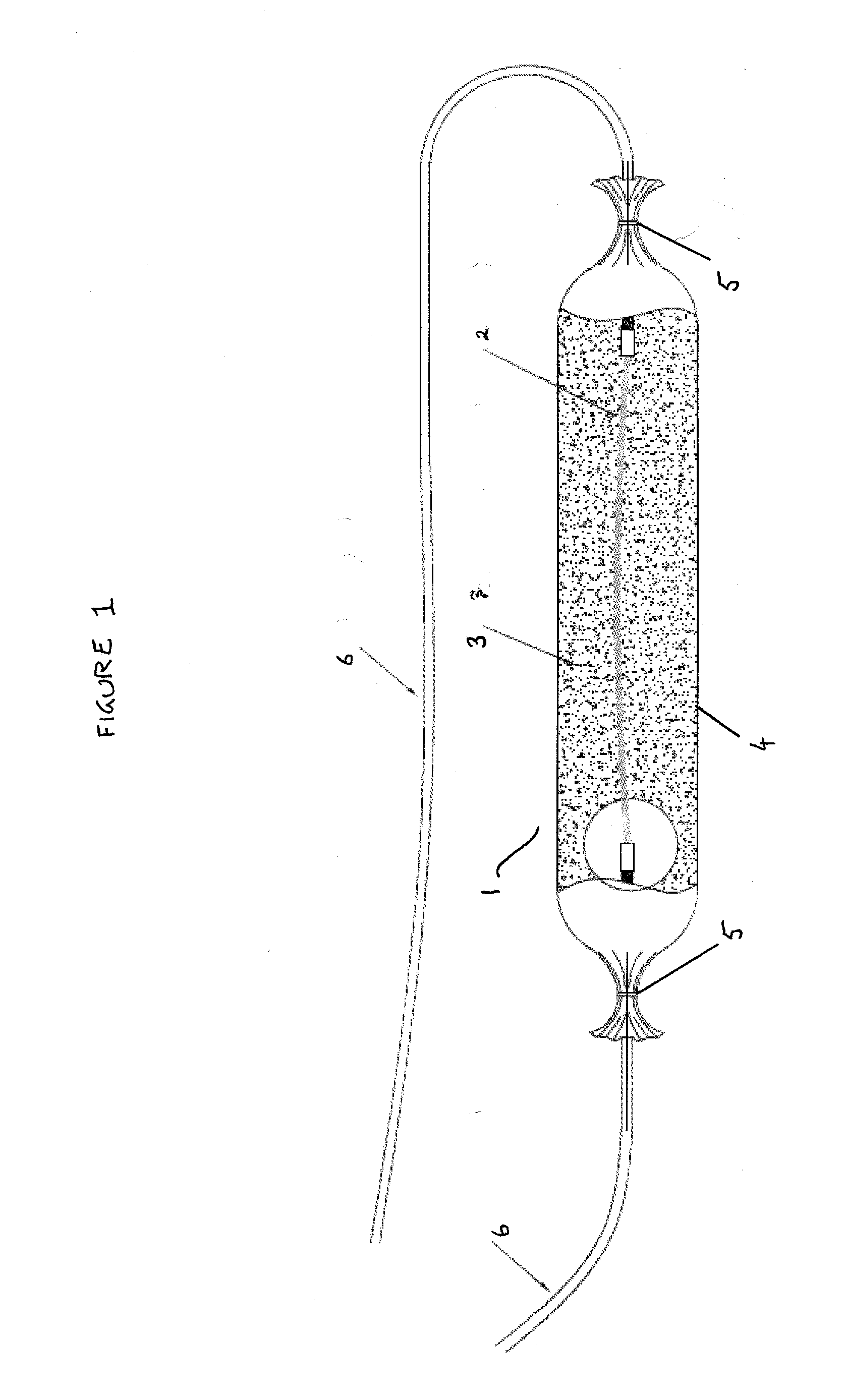

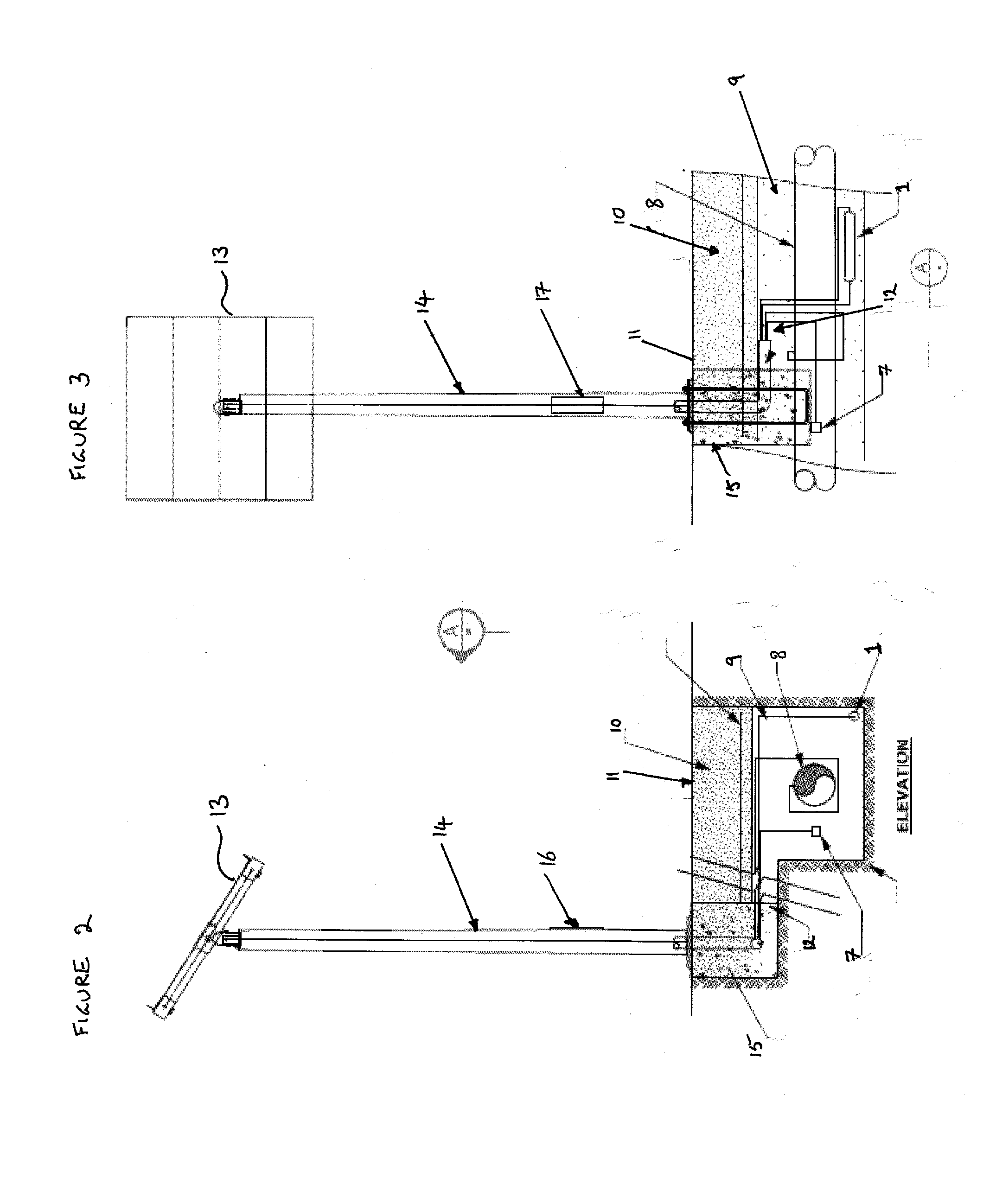

[0044]Referring to FIG. 1, there is shown an impressed current cathodic protection system for steel (& cast iron?) structures (1) which comprises an inert mixed metal oxide (MMO) anode wire (2) surrounded by a zone of calcined petroleum coke (3) contained within a tubular sleeve (4) sealed at both ends (5) and connected via a cable tail (6) to a power supply. Preferably, the system is driven by a DC power supply, which in this embodiment is a sealed battery cell (not shown).

[0045]The system also has an output regulator (not shown) to control the flow of current to the target structure.

In this preferred form of the invention, the specification for the calcined petroleum coke is as follows:

[0046]Fixed carbon: 99.35%

[0047]Ash: 0.6%

[0048]Moisture: 0.05%

[0049]Volatiles: Nil at 950° C.

[0050]Bulk Density: 74 lbs. per cubic foot.

[0051]Predominantly round particles.

[0052]All particles surface modified for maximum electrical conductivity.

[0053]Particle Sizing: Dust free with a maximum particl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com