Highly filled high thermal conductive material, method for manufacturing same, composition, coating liquid and molded article

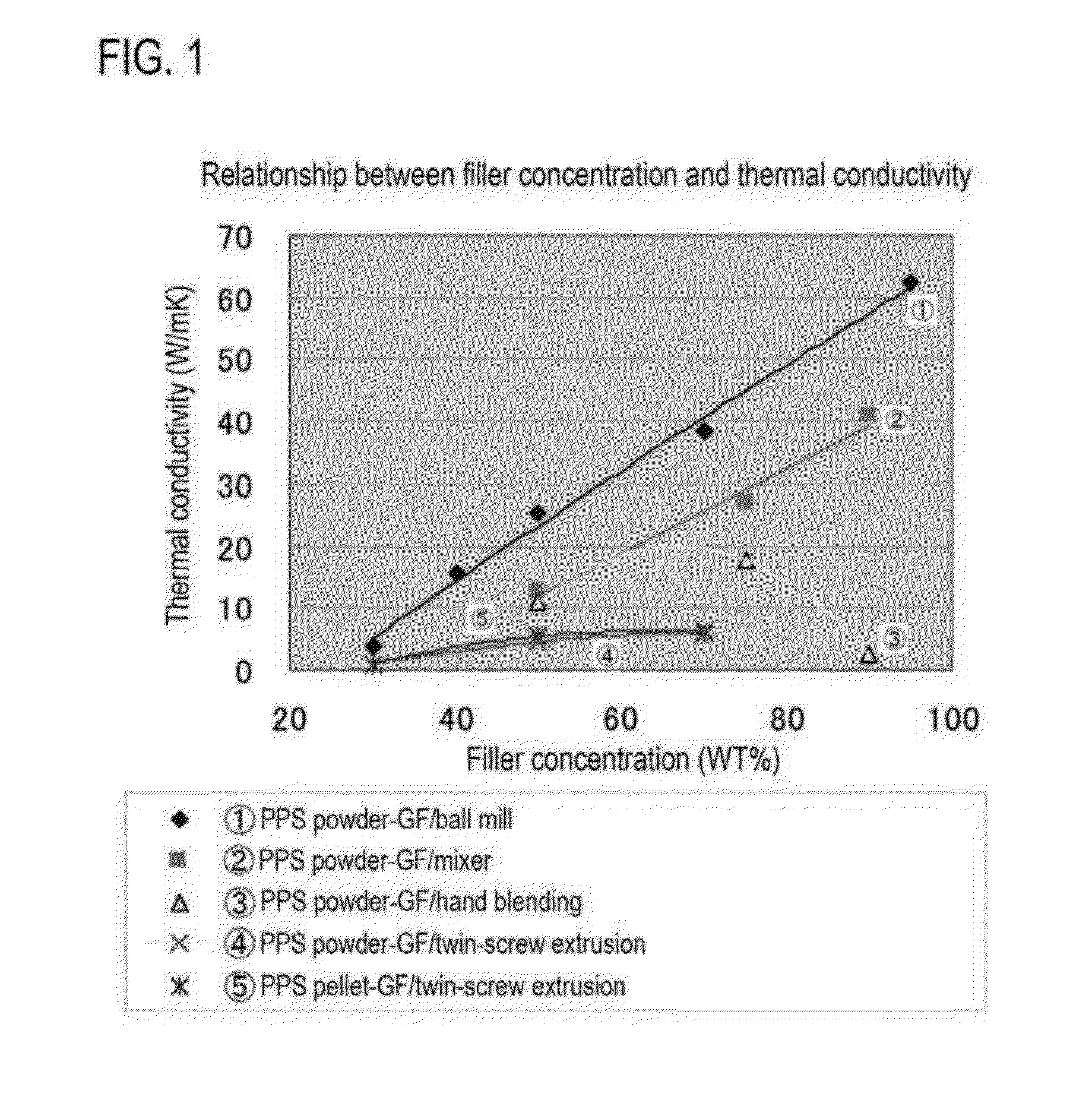

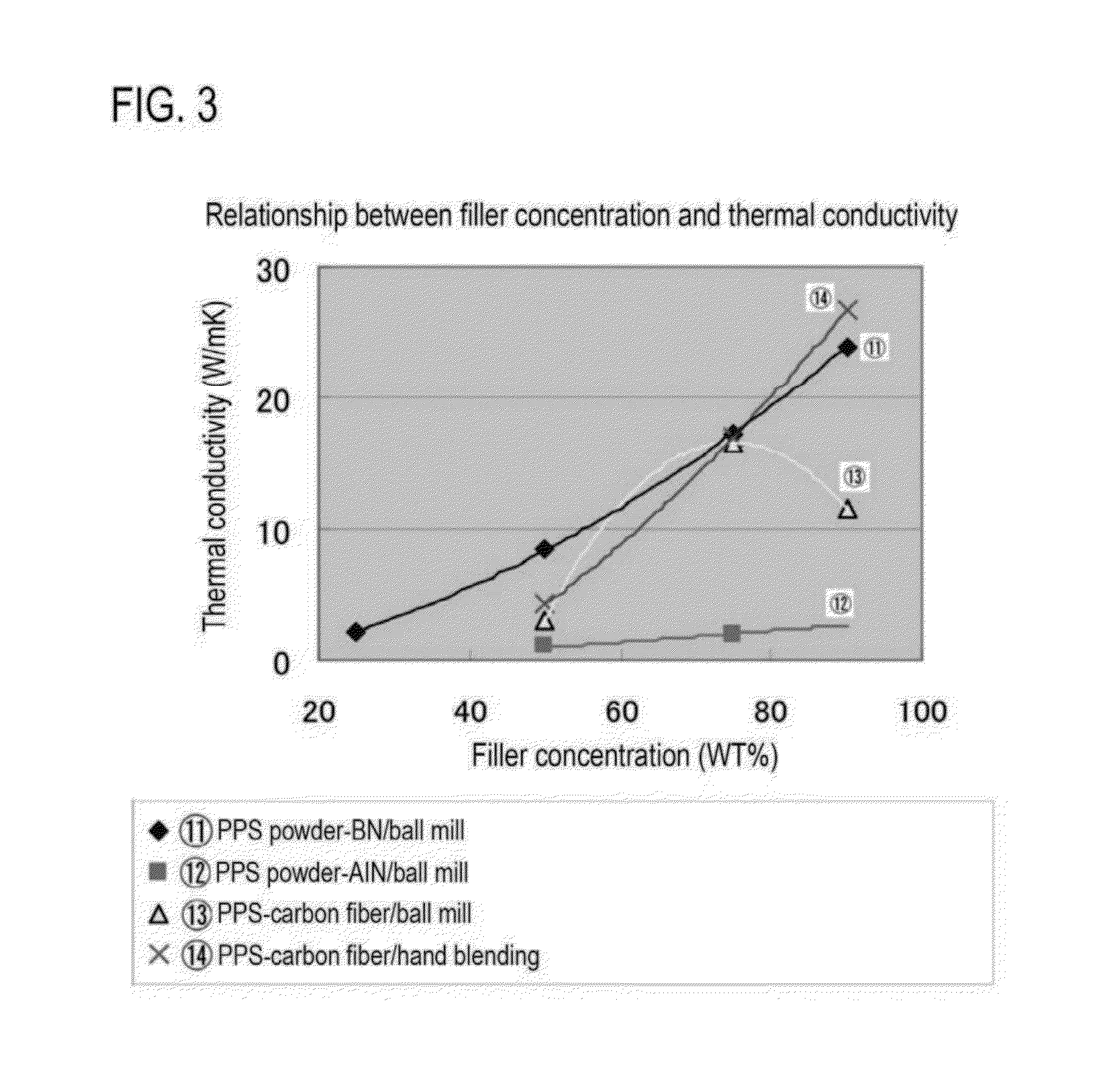

a high-temperature conductive material and high-temperature technology, applied in the field of high-temperature conductive materials, can solve the problems of insufficient manifestation of the advantages of organic polymers, insufficient intrinsic properties of thermally conductive materials, and marked degradation of mechanical properties such as strength of molded articles, etc., to achieve high thermal conductivity, low thermal expansion coefficient, and high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0165]Hereinafter, the present invention will be specifically explained by way of Examples, Comparative Examples and Reference Examples, but the scope of the present invention is not intended to be limited to these. Meanwhile, production and evaluation of raw materials and specimens were carried out as follows.

[0166](1) Raw Materials:

[0167][Organic Polymer Particles]

[0168]Polyphenylene sulfide (PPS) powder: W203A NATURAL manufactured by Kureha Corp., white powder, linear form, particle size 100 to 500 μm, melting point 296° C., heat of fusion 33 J / g, coefficient of thermal expansion 50×10−6° C.−1

[0169]Polyphenylene sulfide (PPS) pellet: FZ-2100BK manufactured by DIC Corp., black pellet, crosslinked type, shape: about 1.5 mm in inner diameter×about 2 mm in length, melting point 280° C., heat of fusion 28 J / g, coefficient of thermal expansion 40×10−6° C.−1

[0170]Polyethylene terephthalate (PET): waste PET bottle recycled product, white flakes, particle size 1 to 2 mm, melting point 2...

examples 8 to 13

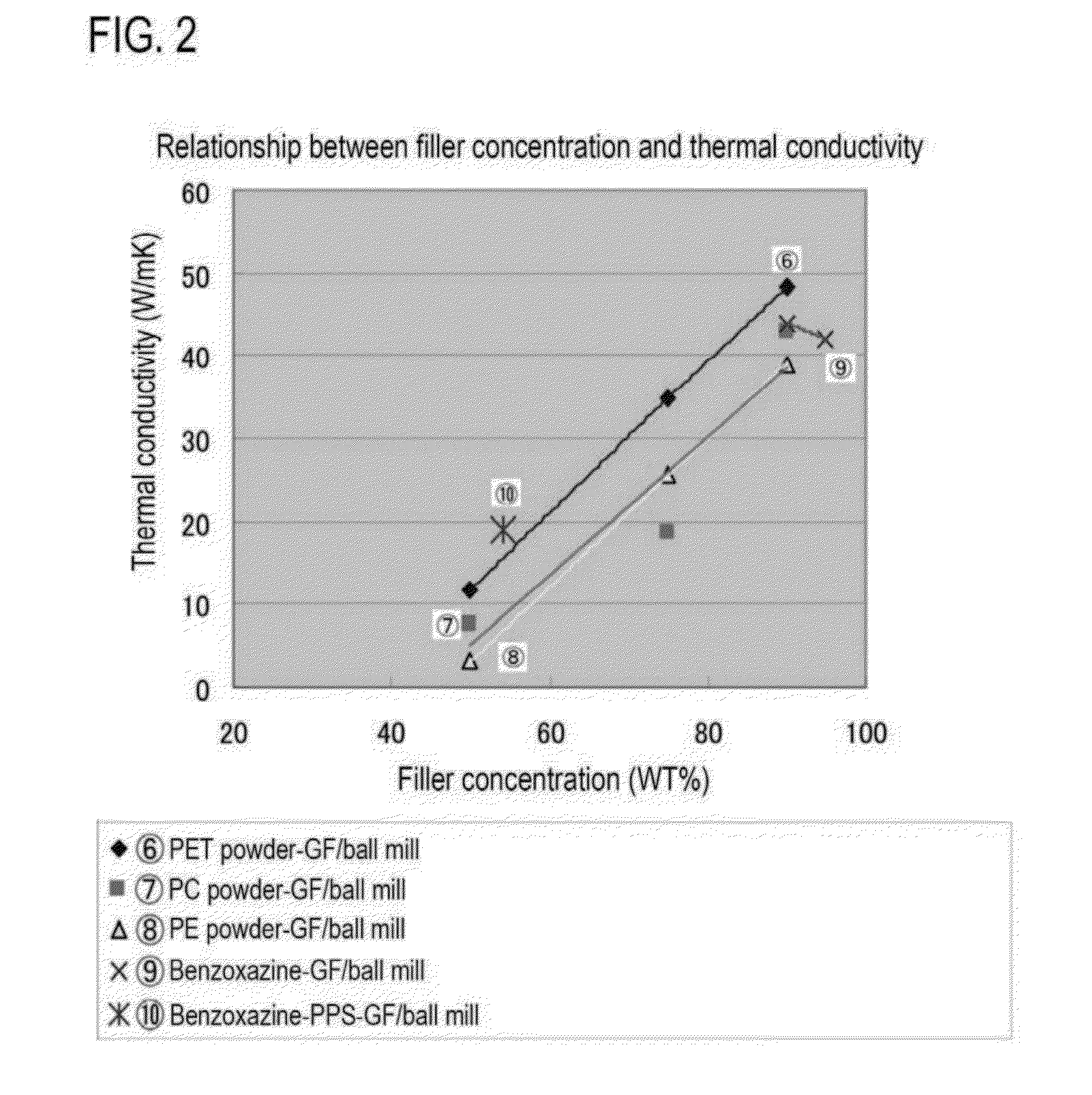

[0211]High filler-loaded high thermal conductive materials were obtained at the compositions of Table 4 by the same method as that used in Example 1, by newly providing a polyethylene terephthalate (PET) powder and a polycarbonate (PC) powder (Examples 8 to 13).

[0212]The density, thermal conductivity, electrical conductivity, coefficient of linear expansion, bending strength, flexural modulus of elasticity, heat of fusion per resin, and heat of fusion per filler of the specimens (molded articles) thus obtained were measured by the same methods as described above. The results thus obtained are presented in Table 4.

[0213]Meanwhile, in regard to PC which is a non-crystalline aromatic resin, the heat of fusion of the raw material powder exhibited a high value such as 26 J / g resin, but the molded article did not exhibit an endotherm peak that represents the melting point. Thus, the molded article was annealed for 2 hours at 180° C. to 240° C., and an endotherm peak corresponding to the m...

examples 14 to 19

[0215]A low molecular weight polyethylene (PE) powder and benzoxazine were newly provided, and high filler-loaded high thermal conductive materials were obtained at the compositions of Table 5 by the same method as that used in Example 1 (Examples 14 to 19).

[0216]The density, thermal conductivity, electrical conductivity, coefficient of linear expansion, bending strength, flexural modulus of elasticity, heat of fusion per resin, and heat of fusion per filler of each of the specimens (molded articles) thus obtained were measured by the same methods as described above. The results thus obtained are presented in Table 5.

[0217]Meanwhile, benzoxazine, which is a thermosetting resin, is a precursor (oligomer) of polybenzoxazine. The heat of fusion of the raw material was 25 J / g, but an endotherm peak corresponding to the heat of fusion of a molded article using this raw material was not observed. It is contemplated that except for the peripheries of the thermally conductive filler particl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com