Photodetector focal plane array systems and methods

a technology of focal plane array and photodetector, applied in the field of imaging systems and methods, to achieve the effects of reducing dark current, increasing speed, and improving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021]By way of enabling background, prior work has taken place in three main areas: i) developing the general concept of photonic nanojets; ii) developing techniques for the self-assembly of microspheres; and iii) developing micro-assembly technologies, such as vacuum or suction tweezers and grippers.

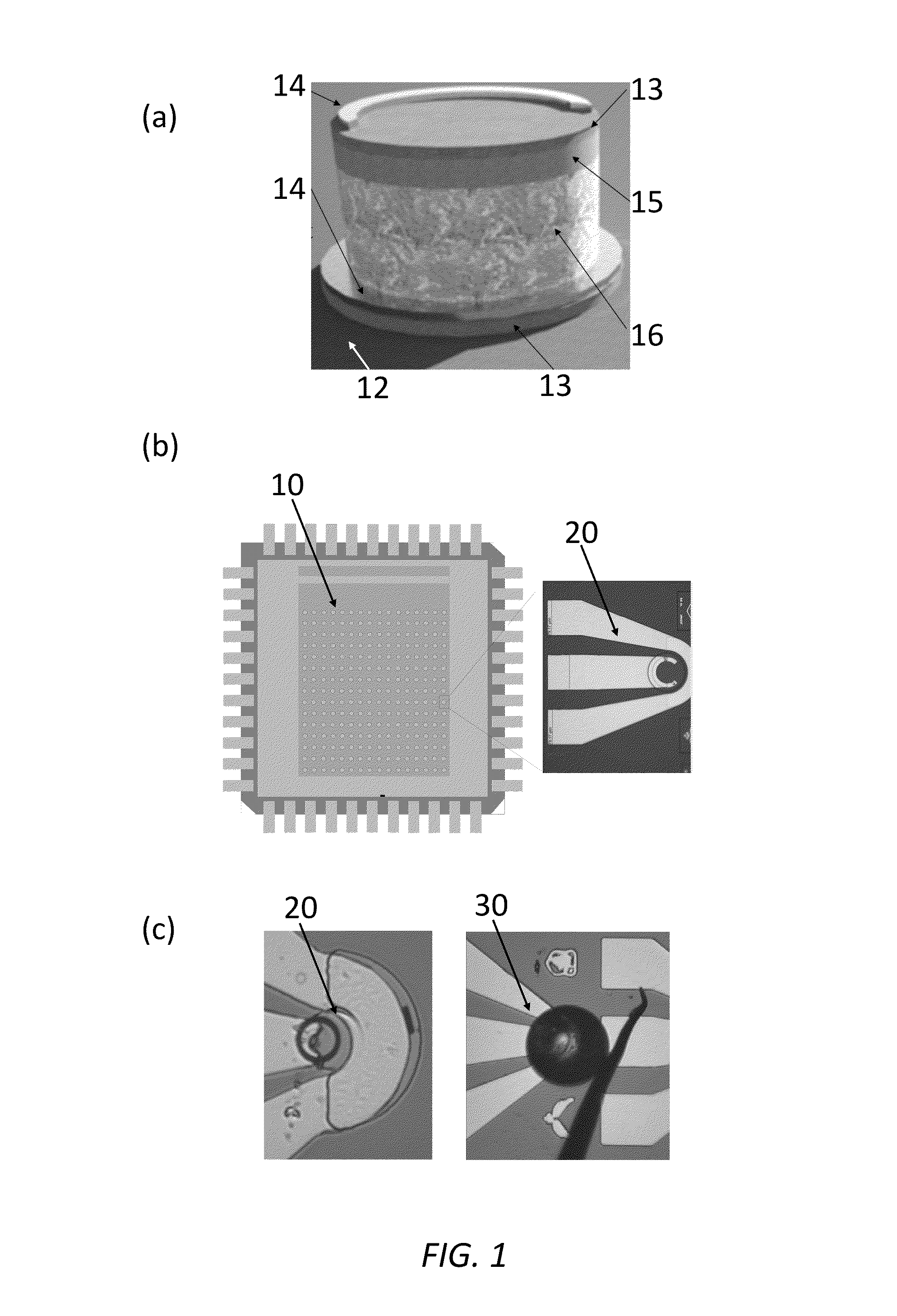

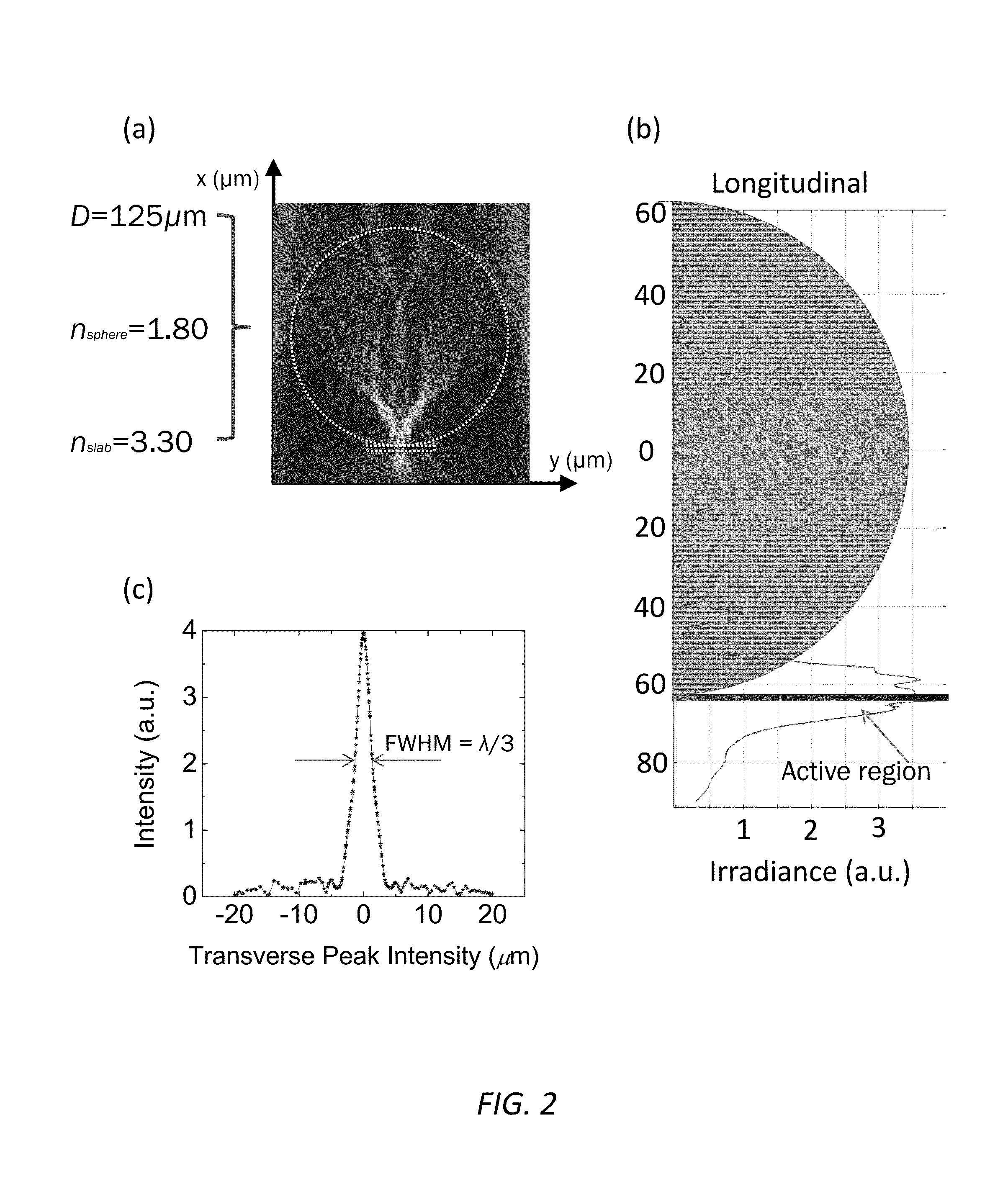

[0022]Photonic nanojets. It has been proposed that dielectric spheres can be used for obtaining tightly focused beams with lateral dimensions which can be smaller than the diffraction limit. Such tightly focused beams have been termed “photonic nanojets.” These photonic nanojets appear for a wide range of diameters of microspheres, typically in a 2λ<D<100λ range, with the refractive index contrast relative to the background typically in a 1.4<n<2.0 range. Many applications of photonic nanojets have been proposed, including polarization filters based on chains of spheres and focusing single-mode and multi-mode microprobes. More recently, an application of photonic nanojets for focusing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com