Method of manufacturing hexagonal boron nitride laminates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018]A method of manufacturing hexagonal boron nitride laminates according to a preferred embodiment of the present invention contains steps of:

[0019]a) Dissolving 10 to 80 wt % dielectric polymers in solvent.

[0020]Preferably, the dielectric polymer is at-least one of the following polymers, including polyethylene terephthalate (PETP), polyphenylene sulfide (PPS), polyetherimide (PEI), polyetherether ketone (PEEK), polyetherketone (PEK), polyimide (PI), Polyvinylidene fluoride (PVDF), phenol resin or acrylic resins.

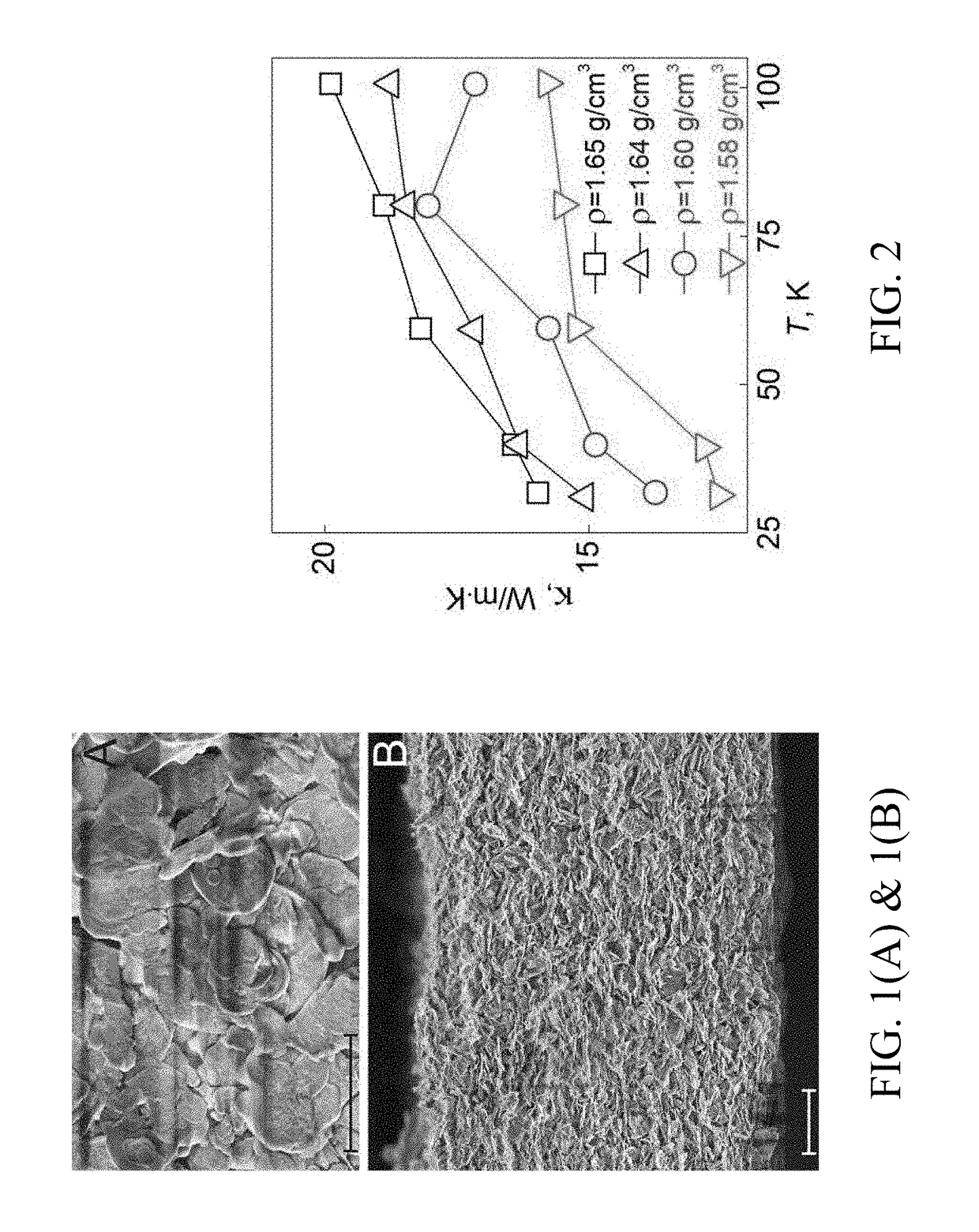

[0021]b) Mixing 20 to 90 wt % h-BN powder to form a well-mixed h-BN coating slurry.

[0022]Preferably, the thickness of h-BN powders ranges from 1 to 500 nm, and the size is from 0.1 to 100 μm.

[0023]c) Coating slurry on substrates and dried at 100 to 150° C. A layer of h-BN laminates was obtained after this process.

[0024]d-1) For free standing h-BN film, peel off h-BN dielectric polymer layer from substrate in water batch by roll to roll process.

[0025]d-2) For h-BN film on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com