High aspect ratio weld face design for dissimilar metal welding

a technology of high aspect ratio and welding face, which is applied in the direction of welding apparatus, manufacturing tools, transportation and packaging, etc., can solve the problems of difficult to effectively control and concentrate heat within the aluminum workpiece, difficult to spot welding an aluminum workpiece to a steel workpiece, and source of near-interface defects in the growing weld pool. , to achieve the effect of improving peel strength, improving overall structural integrity, and less prone to affect the mechanical properties of the weld join

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

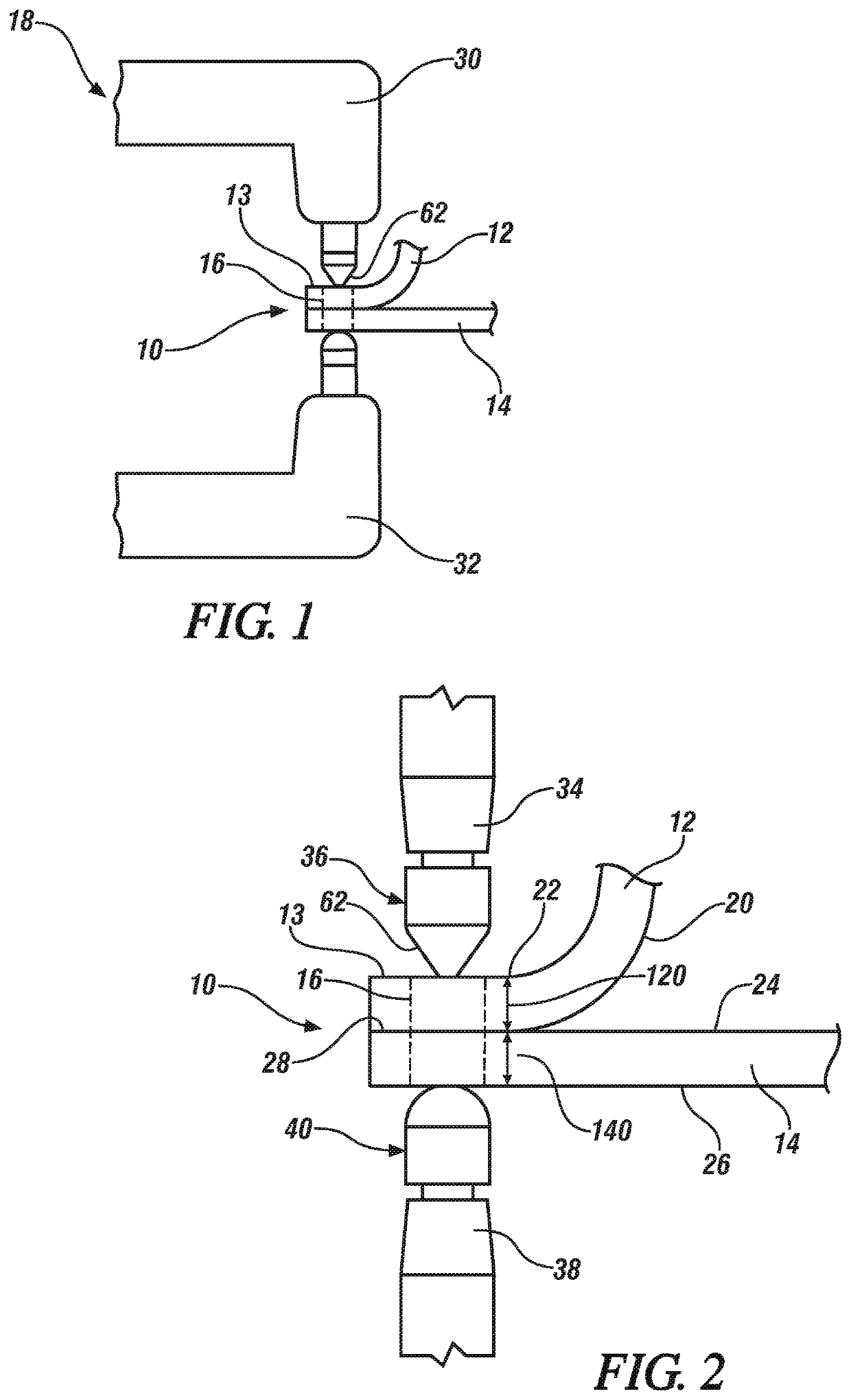

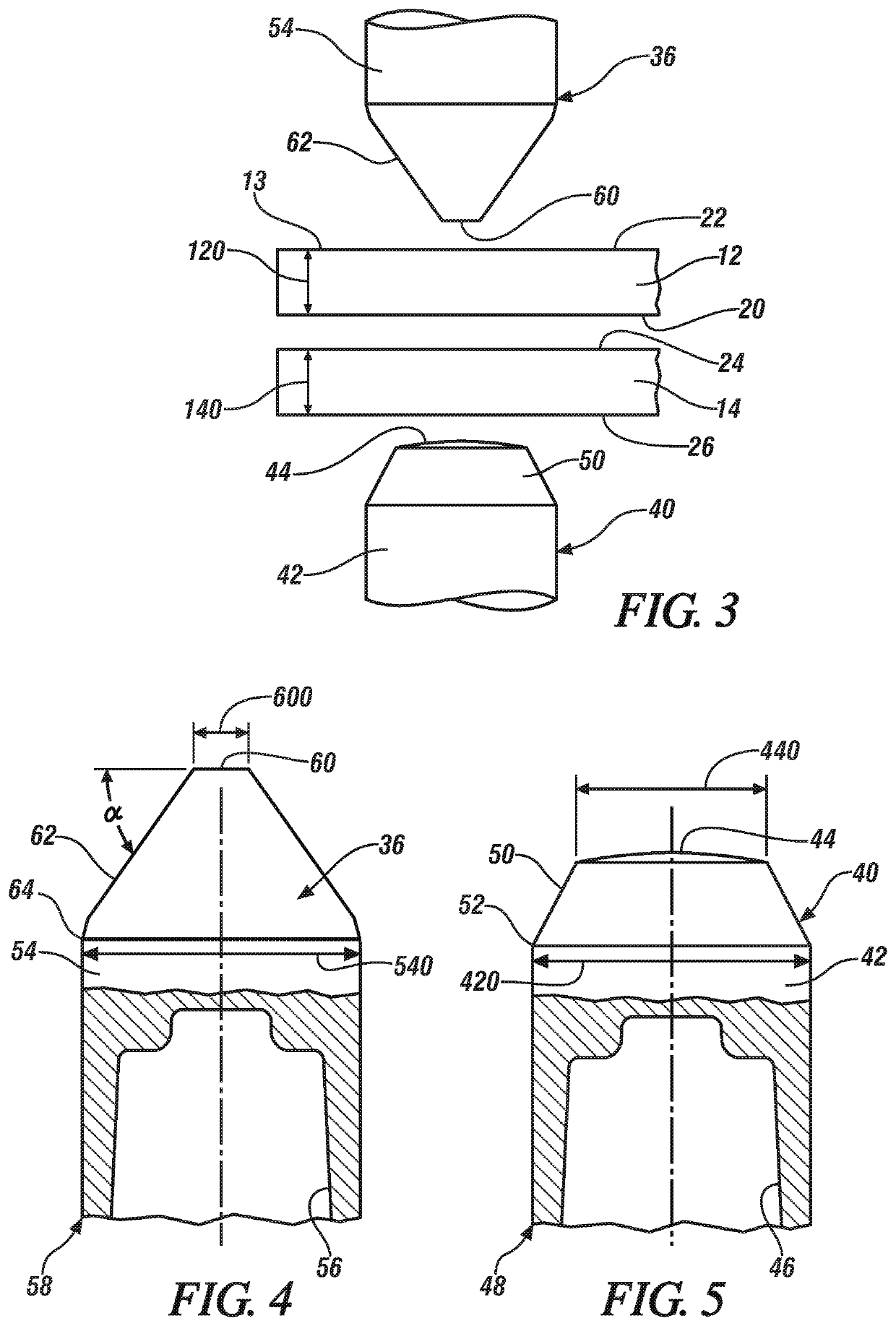

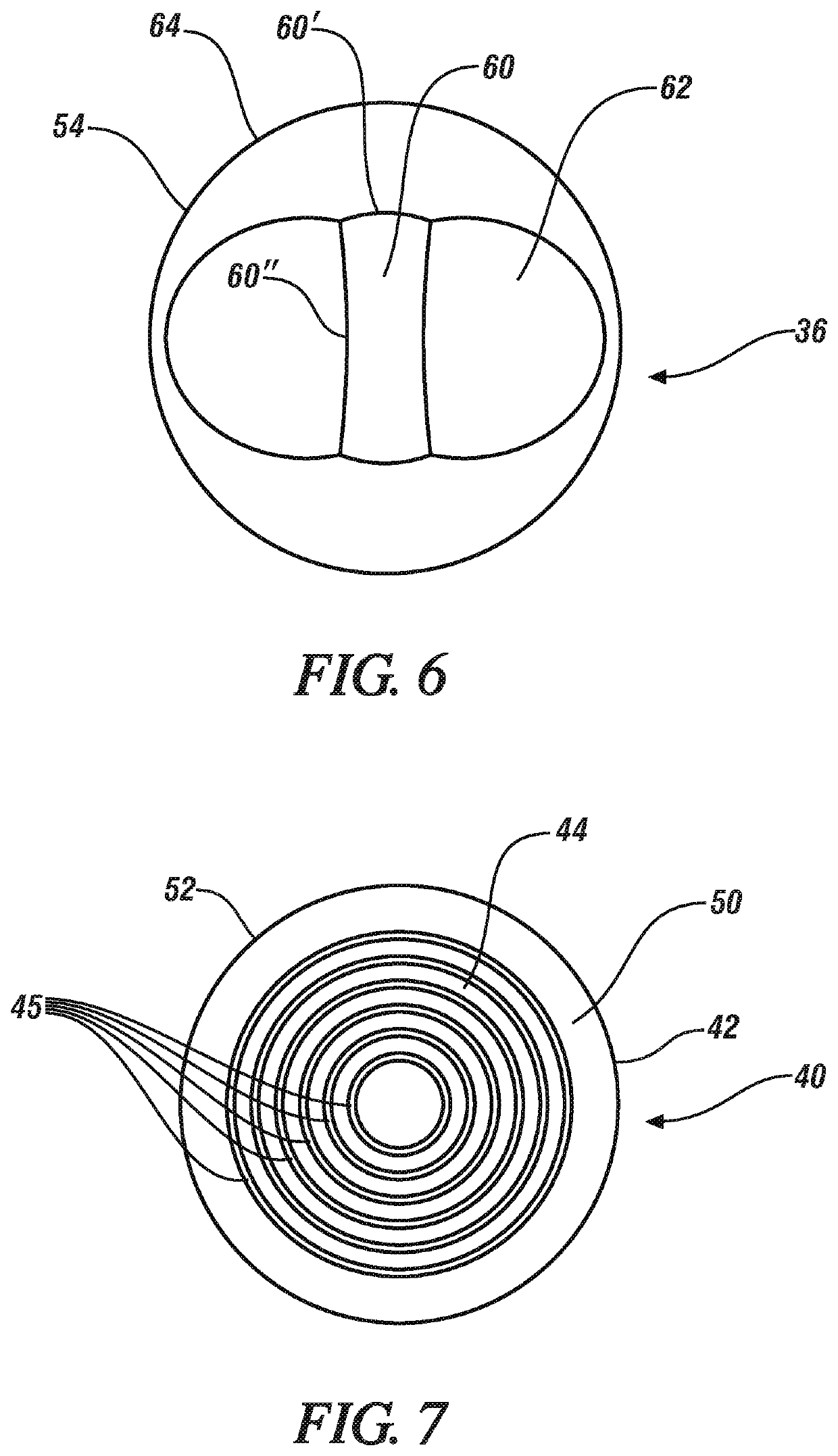

[0028]FIGS. 1-3 generally depict a workpiece stack-up 10 that includes a flanged steel workpiece 12 and an aluminum alloy workpiece 14 that are assembled in overlapping fashion for resistance spot welding at a predetermined weld site 16 by a welding gun 18. In this case, the steel workpiece 12 is characterized by a narrow flange portion 13 for contact with a weld electrode. The aluminum alloy workpiece 14 provides an ample surface area at the intended weld site. The practices of this disclosure may also be utilized when the stack-up includes a second aluminum alloy workpiece placed, side-to-side, against the outer surface 26 of the aluminum alloy workpiece 14, stacked against the narrow flange portion 13 of the steel workpiece 12. Also, the practices of this invention may be utilized when the stack-up includes a second steel alloy workpiece placed side-to-side against surface 20 of the steel workpiece 12. In this illustration, neither a second aluminum workpiece nor a second steel w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com