Thin film ferroelectric light modulators

a ferroelectric light and thin film technology, applied in the field of electro-optical modulators, can solve the problems of inconvenient production of large-scale hybrids, inconvenient manufacturing, and difficult production of hybrid integrated circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

##ic example # 1

PROPHETIC EXAMPLE #1

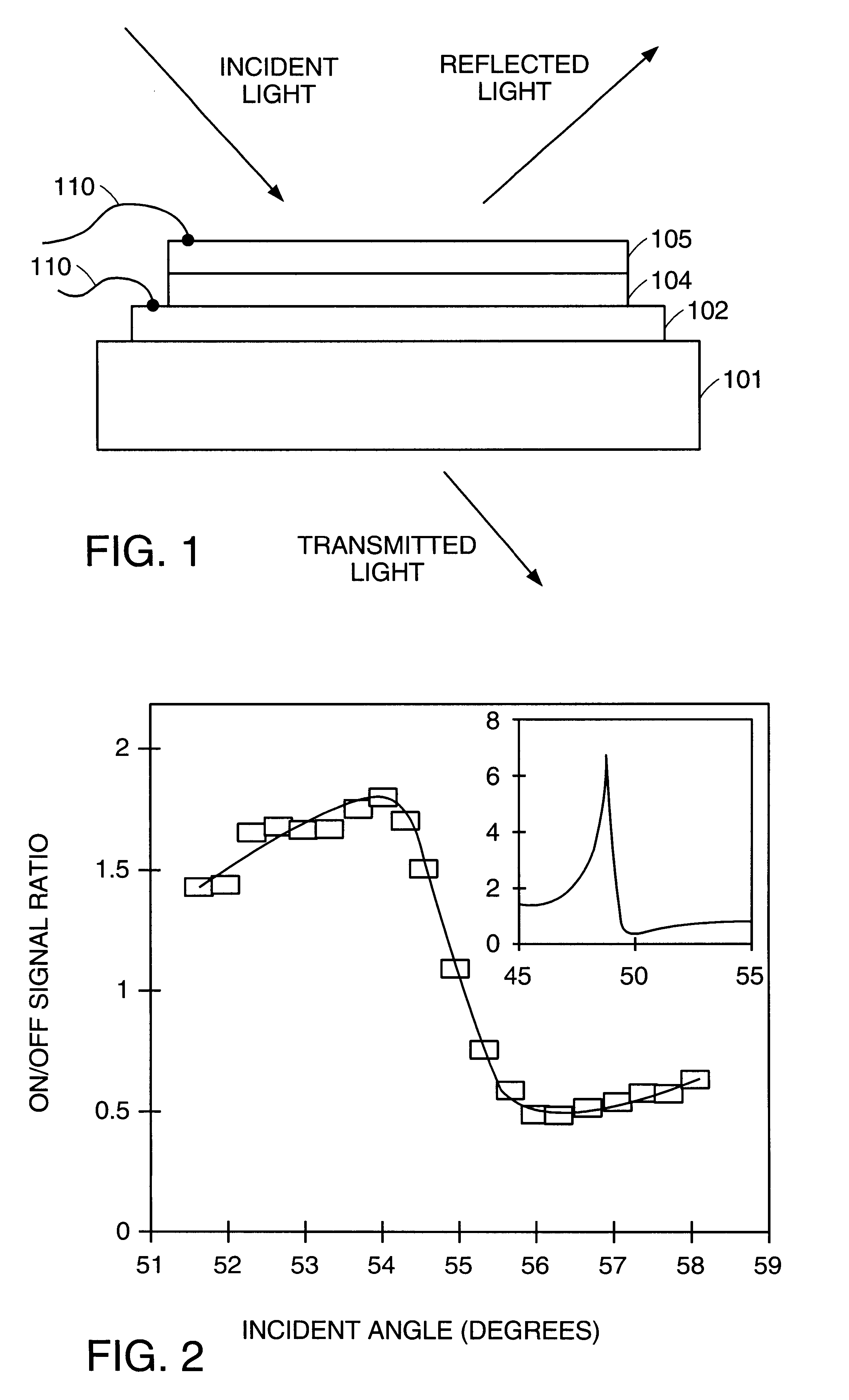

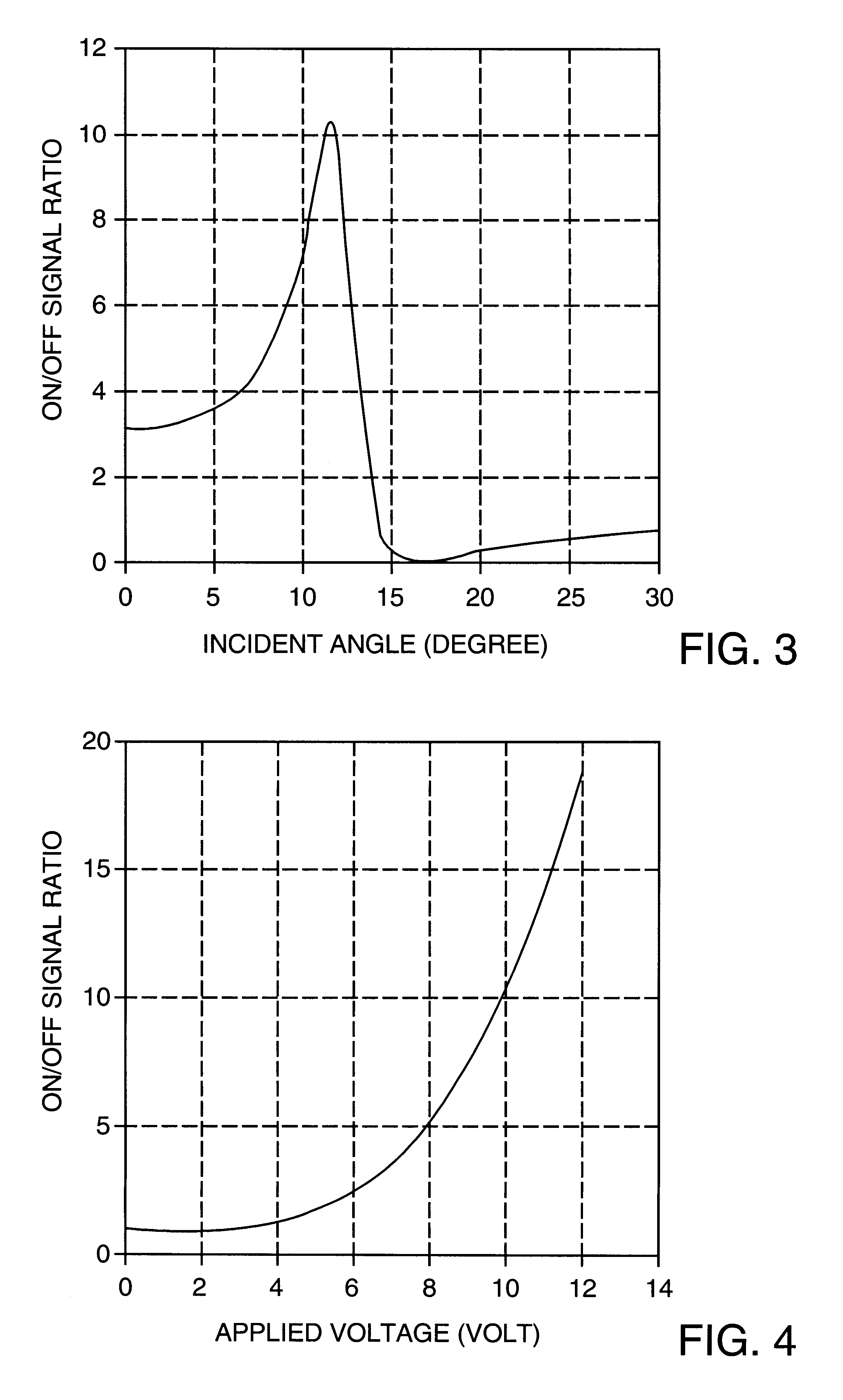

As the angle of the incident light approaches the normal to the structure, the difference between s and p-wave reflections approaches zero. In this case, one may use totally unpolarized light and still obtain a high ratio of on and off signals. FIG. 3 shows a theoretical calculation for small angles for unpolarized light with a 10 volt modulation voltage applied to the ferroelectric. This was for an ITO thickness of 0.25 wavelengths and a PLZT thickness of 1.278 wavelengths of the light. In general, using equation (1), an optimum thickness can be determined for the ITO and PLZT layers for any given incident angle and wavelength. The major limitation on the on / off ratio is the minimum off intensity which depends on how closely one can satisfy equation (3).

Even though the modulator is not bistable but produces continuous modulation with applied voltage, it is convenient to measure modulation as the ratio of reflectance when some fixed voltage is applied and none. F...

working example # 2

WORKING EXAMPLE #2

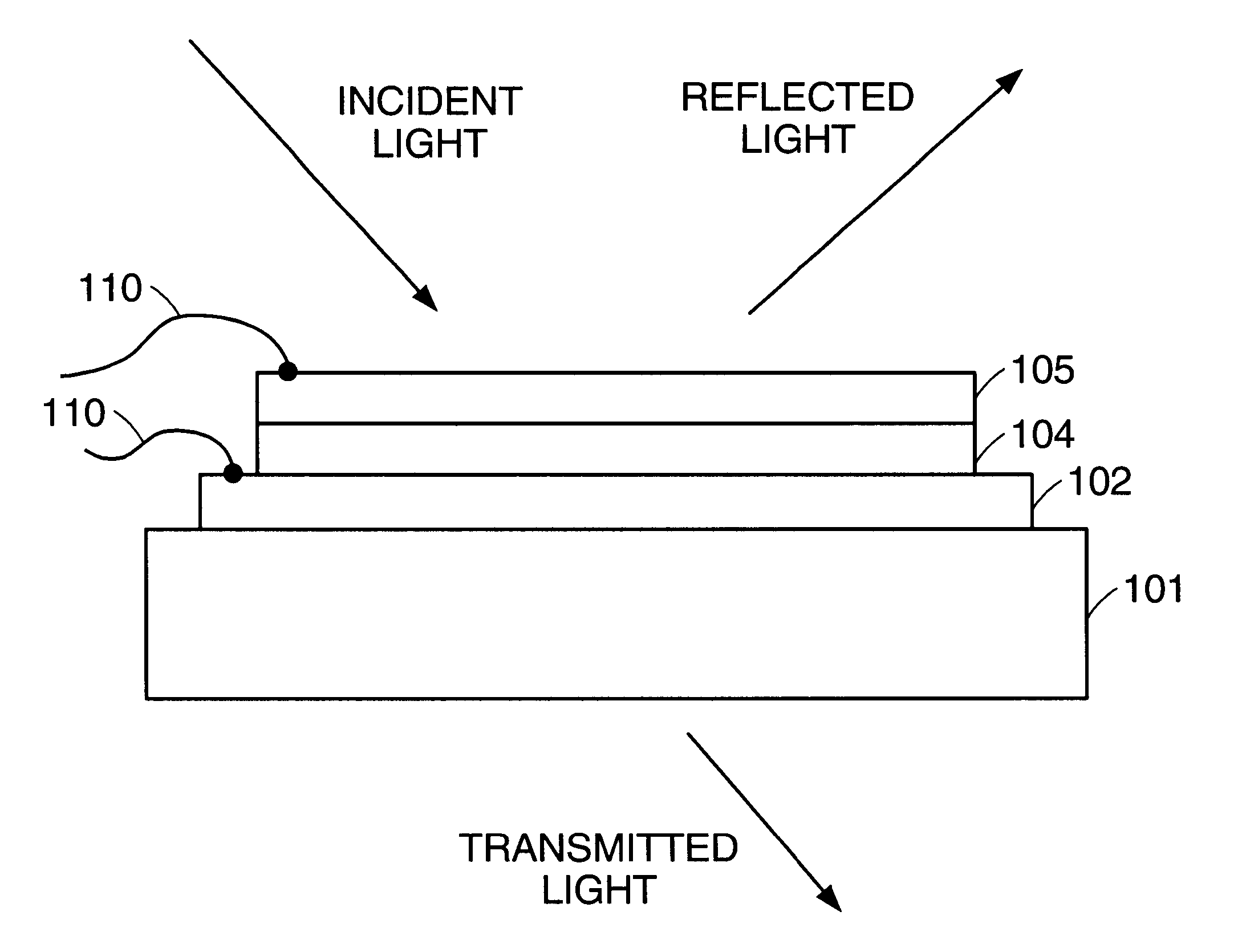

A device was constructed as illustrated in FIG. 5 wherein the bottom mirror / electrode 102 of FIG. 1 was comprised of a dielectric mirror 202 and conductive transparent layer of ITO 203. The use of a stack of layers of alternating index of refraction material to produce nearly perfect mirrors at selected wavelengths is well known, but producing crystalline thin film oxide ferroelectrics on such a dielectric mirror is believed to be unknown.

PLZT thin films can be made by a variety of methods. In this working example, one was made using the Metalorganic Chemical Liquid Deposition (MOCLD) process, K. K. Li, G. H. Haertling and W. -Y. Howng, "An Automatic Dip Coating Process for Dielectric Thin and Thick Films," Integrated Ferroelectrics, vol. 3, pp 81-91 (1993). Dip coating is an old art used for a variety of materials. As described in this reference for PLZT, a solution of acetate precursors of the constituents is prepared and a substrate is dipped, withdrawn, allowed...

##ic example # 2

PROPHETIC EXAMPLE #2

As noted above, using a dielectric stack for the top mirror function as well as the bottom one, as shown in FIG. 7, should result in a major improvement over using gold for the top mirror / electrode. The figure illustrates a substrate 101, a bottom dielectric stack 202, a bottom transparent electrode 203, a ferroelectric film 104, a top transparent electrode 305, and a top dielectric stack 306. Alternating SiO.sub.2 and Ta.sub.2 O.sub.5 layers could be used for the top dielectric stack 306 as well as the bottom 202, but, since the ferroelectric film 204 is formed first, high temperature materials are not required for the top stack 306 and others may be more convenient.

As is well known, the reflectivity of a dielectric stack increases with the number of layers in a predictable manner. In this calculation, enough were chosen so that, coupled with the ITO electrodes, the combination possessed a reflectivity of 98.9%. Using such a combination for both the top and bott...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectivity | aaaaa | aaaaa |

| thick | aaaaa | aaaaa |

| thick | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com