Laser wavelength control unit with piezoelectric driver

a technology of piezoelectric driver and laser, which is applied in the direction of instruments, photomechanical equipment, active medium materials, etc., can solve the problems of insufficient correction of large and sudden wavelength shifts, insufficient prior art wavelength correction techniques, and insufficient correction of small very rapidly occurring (high frequency) wavelength shifts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

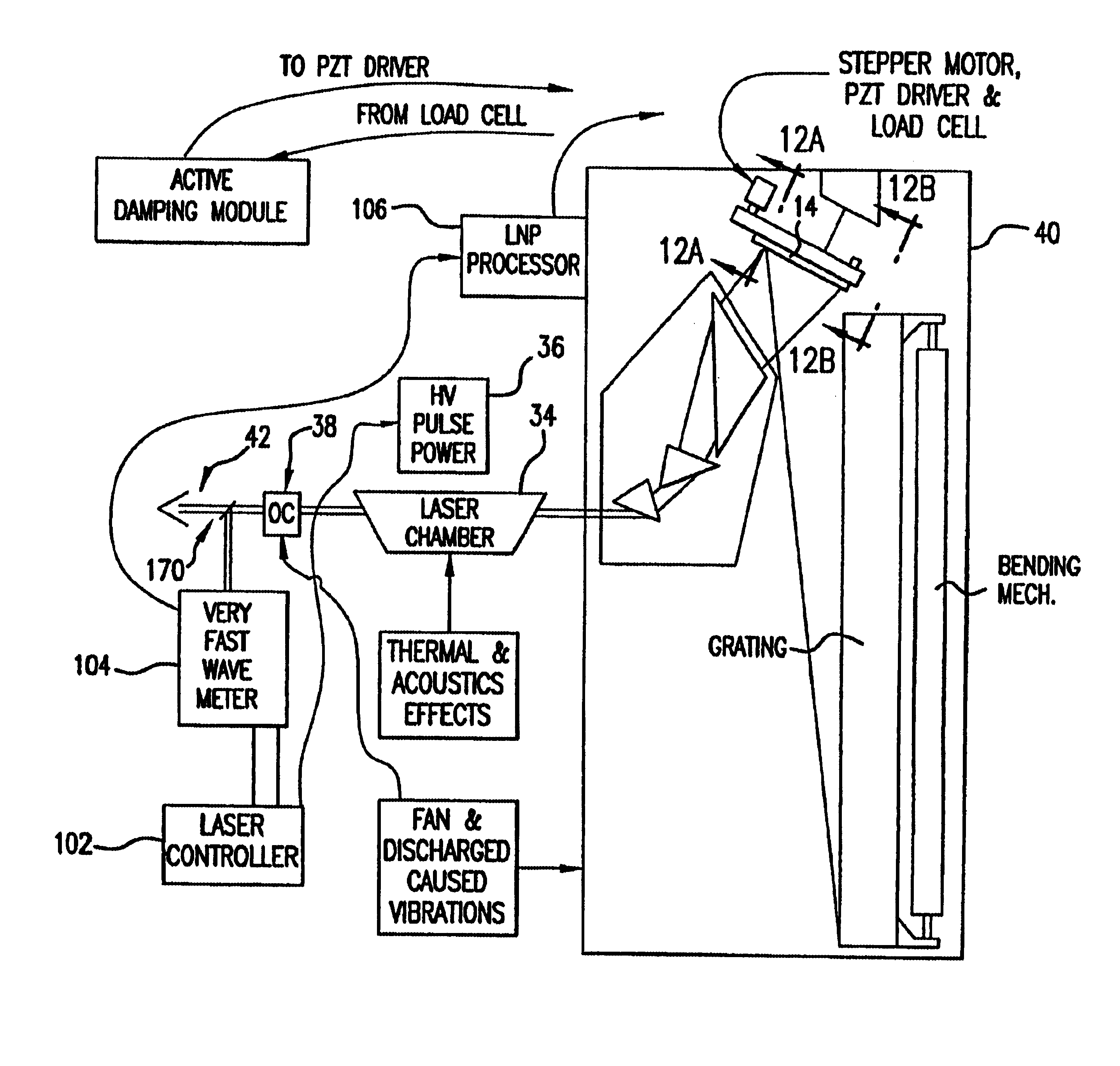

Important features of a first preferred embodiment of the present invention are shown in FIG. 4. This embodiment shows a KrF excimer laser system useful as a light source for integrated circuit fabrication. The system includes laser chamber 34 which contains a laser gas circulated with a motor driven fan (not shown) between two elongated electrodes (not shown) between which electric discharges are produced at rates of up to 4,000 Hz by a pulse power system 36 controlled by laser controller 102. A resonant cavity defined by output coupler 38 and LNP 40 produces laser beam 42. A portion of laser beam 42 is monitored by very fast wavemeter 104 which provides pulse energy measurements to laser controller 102 for feedback control of the pulse power unit 36 for maintaining pulse power within desired limits. Wavemeter 104 also measures the center-line wavelength of the laser beam and provides a feedback signal to LNP processor which uses the feedback signal to control a stepper motor 82 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com