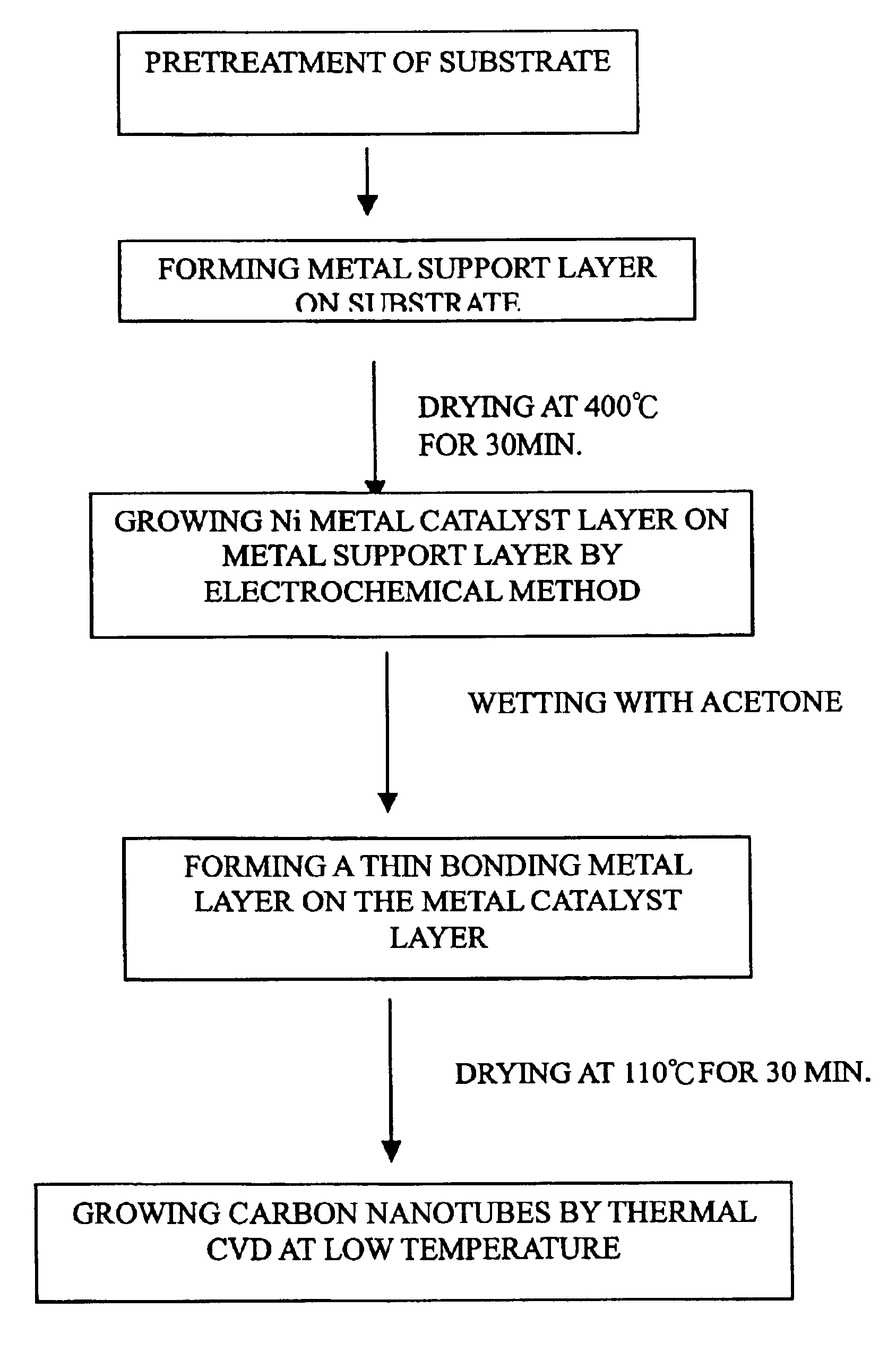

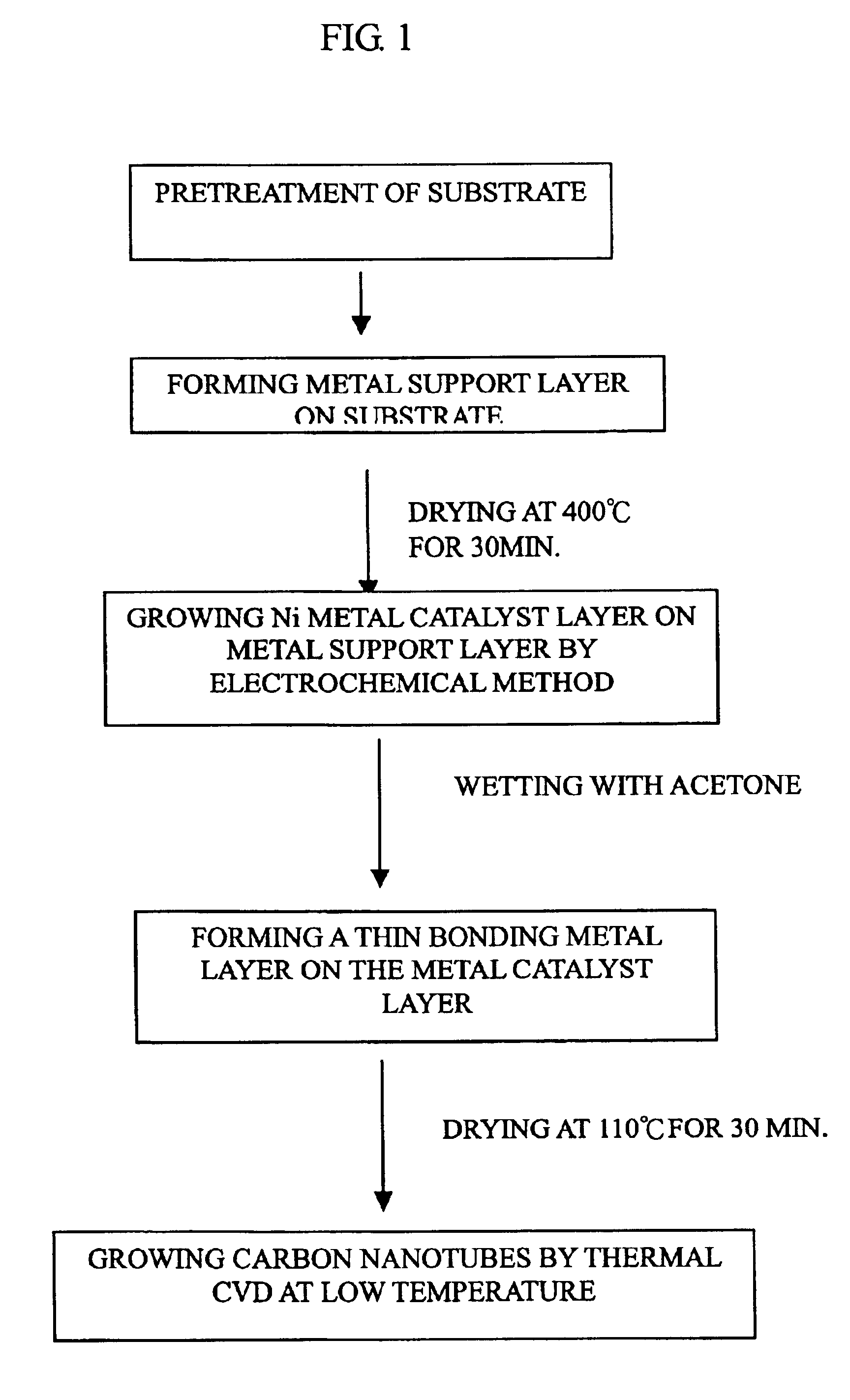

Process of direct growth of carbon nanotubes on a substrate at low temperature

a carbon nanotube and substrate technology, applied in the manufacture of electrode systems, superimposed coating processes, electric discharge tubes/lamps, etc., can solve the problems of difficult control, difficult uniform distribution of carbon nanotubes in said conductive paste, cumbersome technique, etc., and achieve easy preparation of catalyst systems. , the effect of easy composition adjustmen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

The invention of the present application discloses a process of direct low-temperature growth of carbon nanotubes on a substrate, which is different from a consuming-type growth of nano-grade catalytic metal particle disclosed in the abovementioned EP applications. The process of the present invention uses an addition method to prepare the catalyst. Firstly, the surface of a substrate is coated with a layer of a catalyst support, which does not need to be removed. That is the support will not affect the downstream process and the product thereof. Take the CNT-FED as an example. The silver particles in the silver paste can be used as the catalyst support. Since the silver paste is a necessary surface adhesive in the CNT-FED fabrication process, the catalyst support does not need to be removed from the substrate and can be directly used in the CNT-FED fabrication process. A layer of an active metal catalyst is then formed on the surface of the catalyst support; and a relatively thinne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| reaction temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com