Method of preparing solar cell front contacts

a solar cell and front contact technology, applied in the field of preparing can solve the problems of high power dissipation, low efficiency, and low efficiency of solar cell front contacts, and achieve the effects of reducing carrier recombination losses, good barrier, and high sheet resistan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

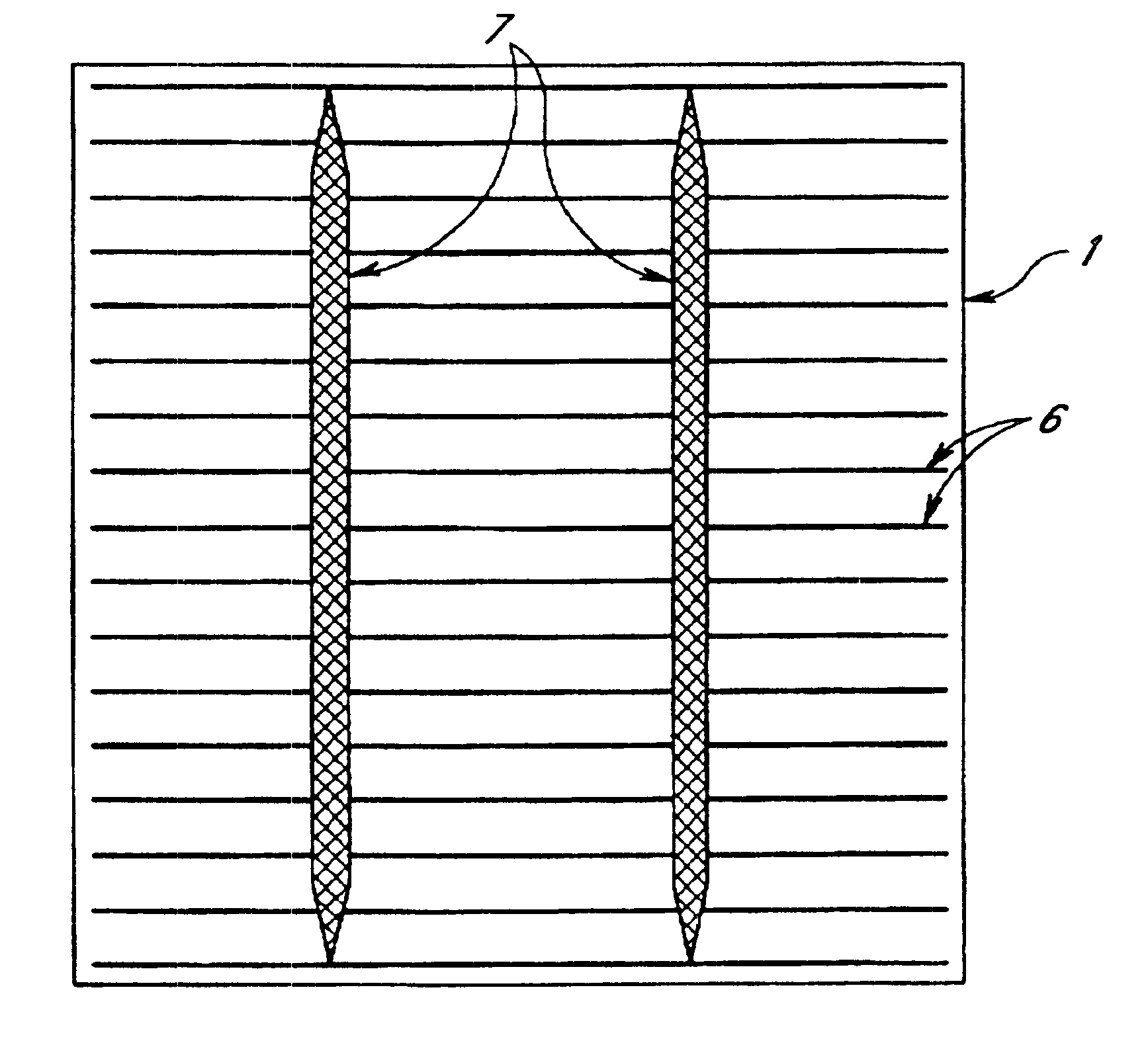

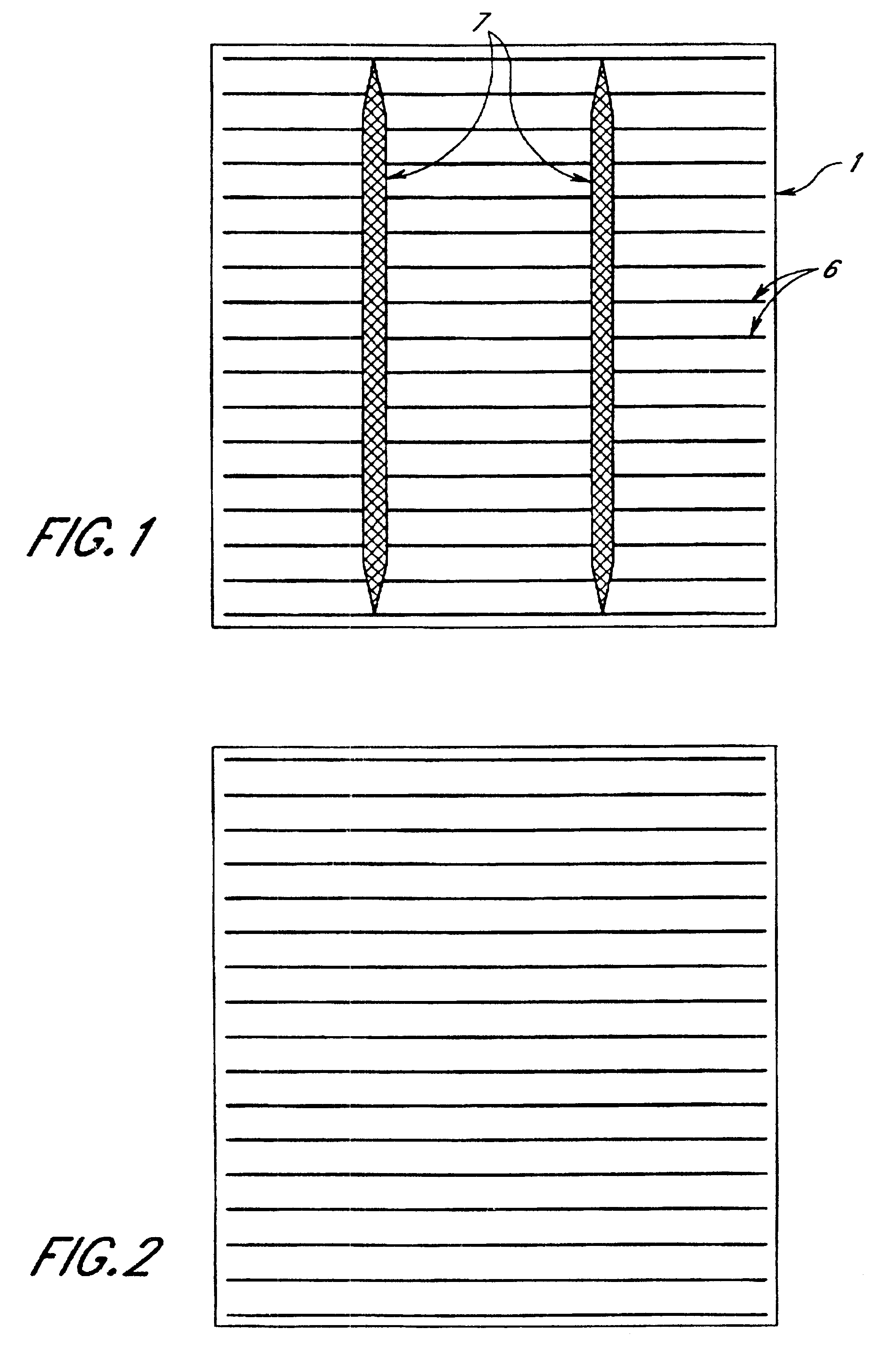

Image

Examples

Embodiment Construction

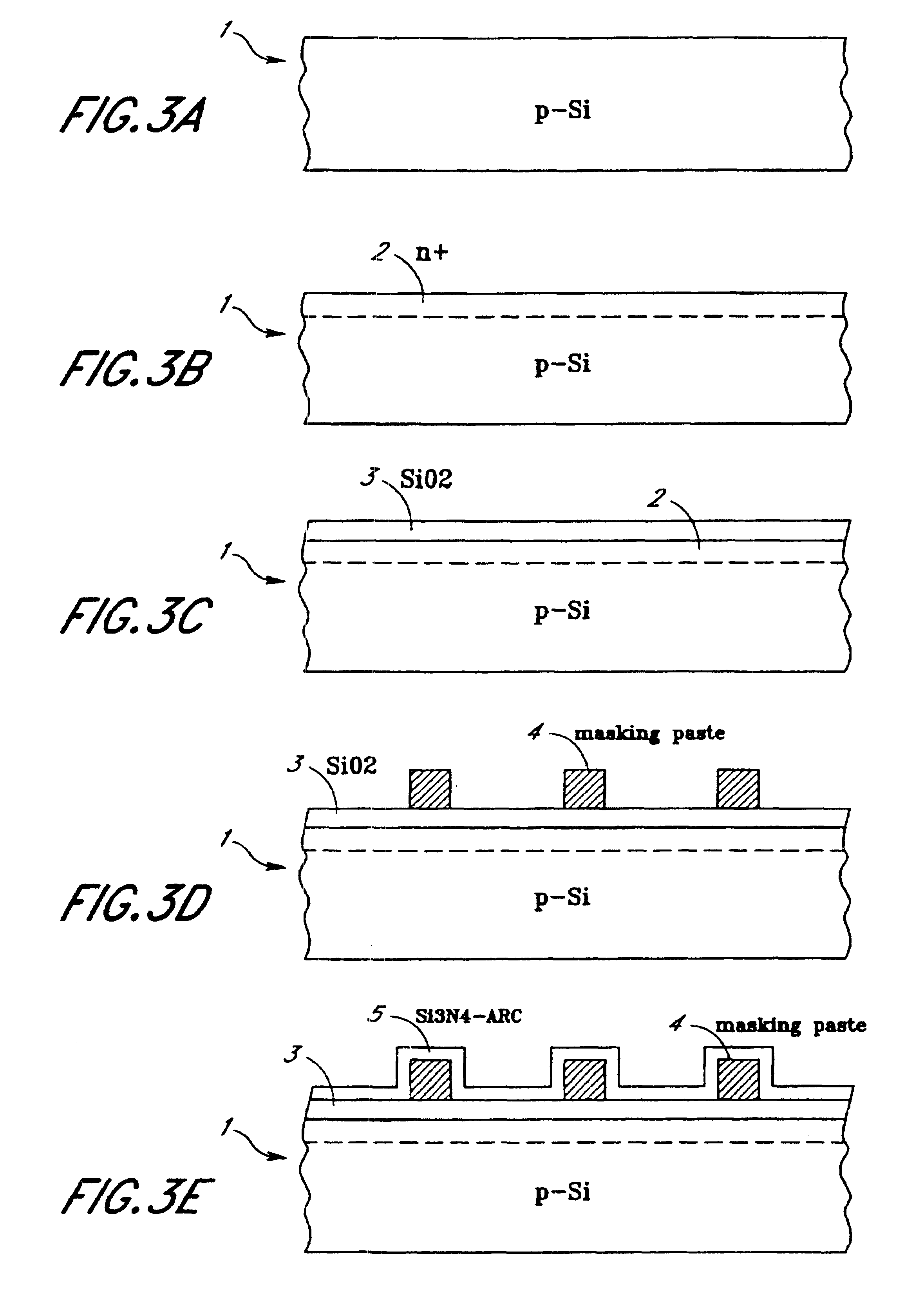

I. Preparation of Screens

1. A standard fabric screen is stretched and glued to a frame adequate to the screen printer used. Typical parameters are metal screen of 80 UT, orientation of wires to the frame at an angle of 90.degree., and tension of the screen 30N.

2. An emulsion typical for screen patterning is deposited over the screen and dried.

3. A solid metal foil with thickness of 40-60 .mu.m is bonded at its peripheries to the standard fabric screen stretched to the frame. The meshes of the fabric screen are cut away from the middle region of the foil where the pattern will be formed.

4. A set of parallel lines reflecting the finger pattern of solar cell contacts is cut by a laser beam. An electron or iron beam can also be used for the cutting process. The width of the cut lines is regulated by the beam diameter, the power, and the cutting speed. A typical contact flager screen consists of lines with width of 40-50 .mu.m and a distance between them of 1.2-1.5 mm cut in a stainless ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com