Catadioptric projection systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035]For purposes of describing the invention, a “lens element” is a single lens (i.e., a single piece of “glass”); a lens “group” or “subgroup” comprises one or more lens elements. A positive lens, lens group, or subgroup has a positive focal length; a negative lens, lens group, or subgroup has a negative focal length. An “optical axis” is a straight line through centers of curvature of surfaces of optical elements. As will be apparent, an optical system can have more than one optical axis. Distances from an off-axis point to an optical axis are measured along a line through the point and perpendicular to the optical axis.

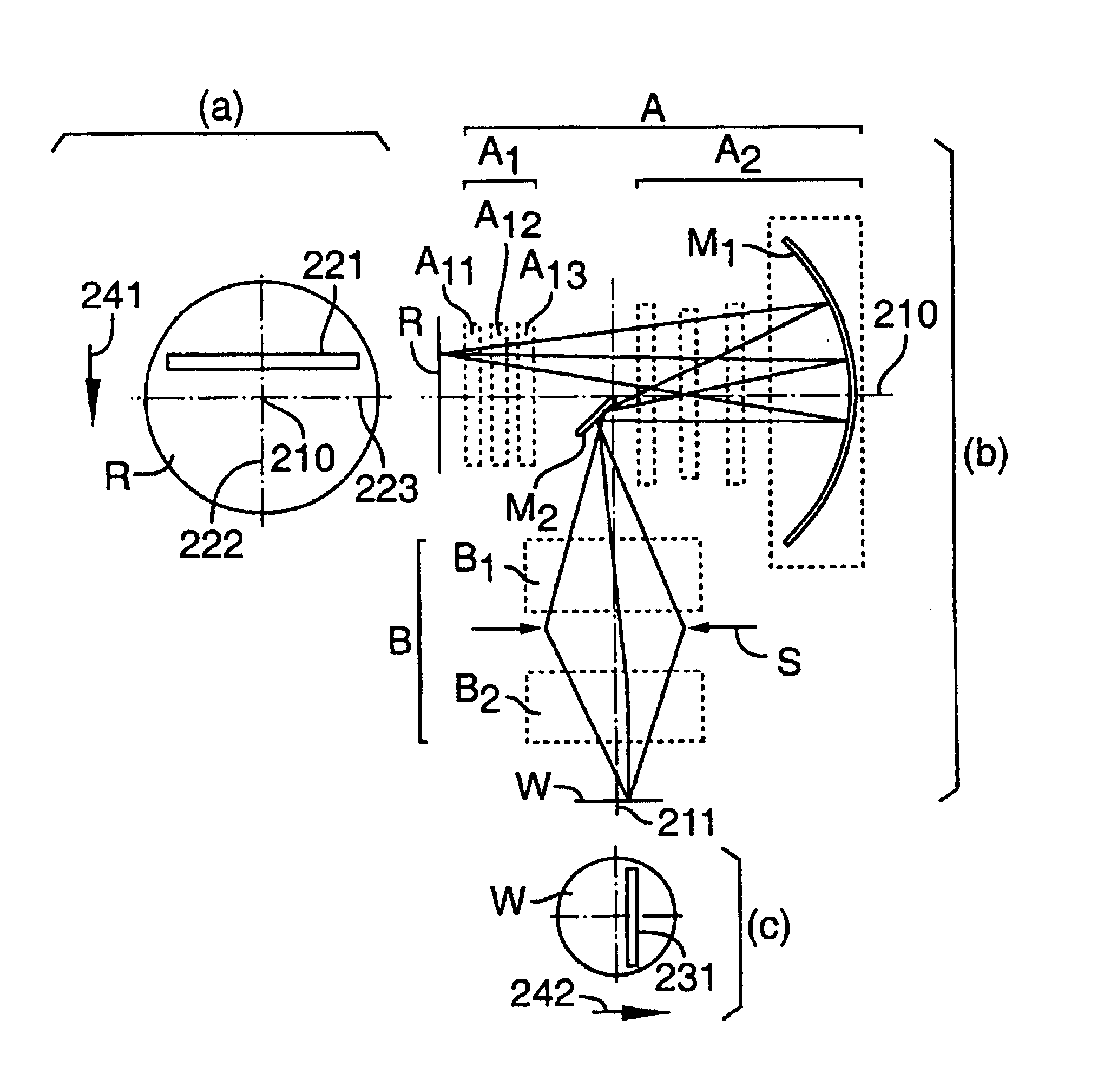

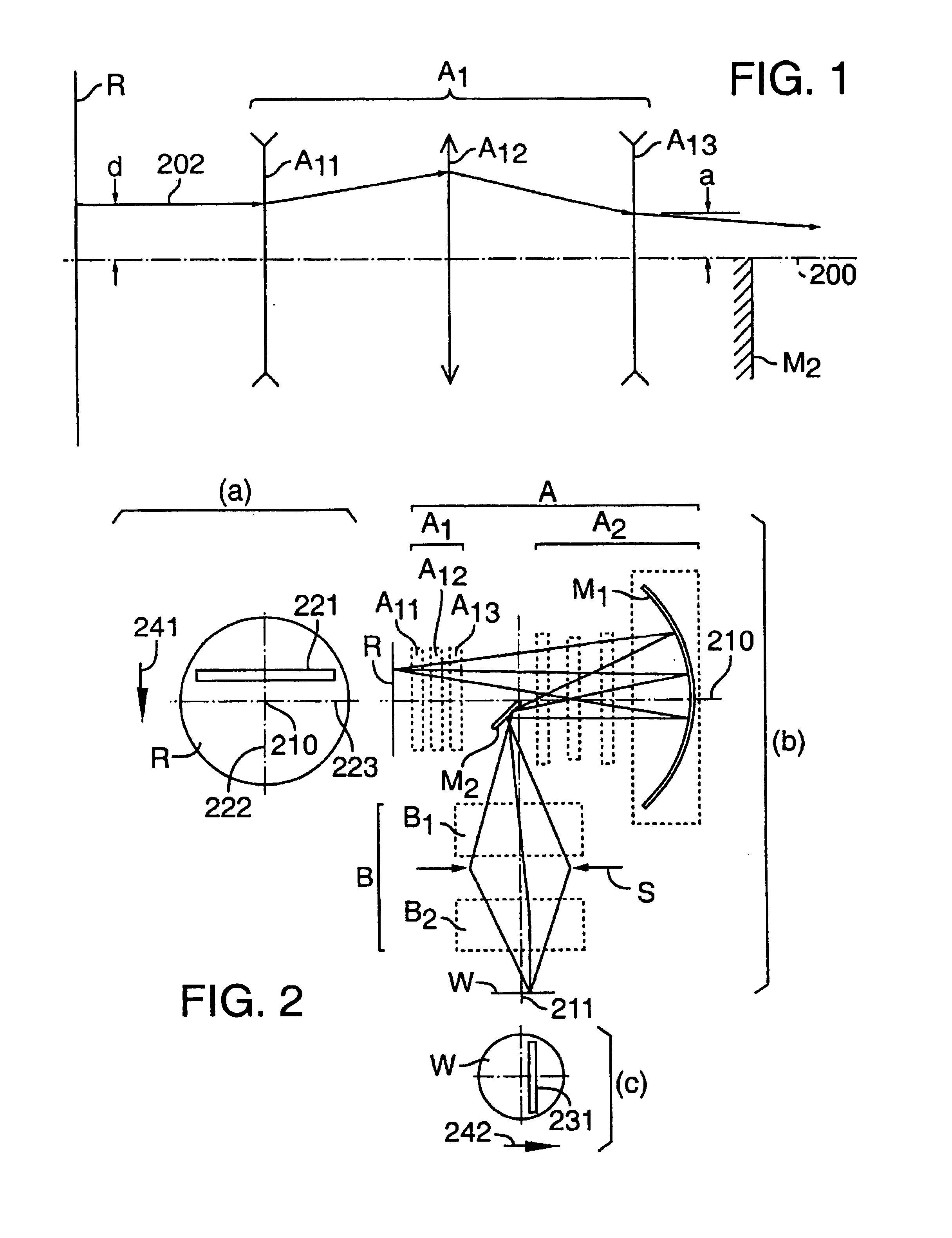

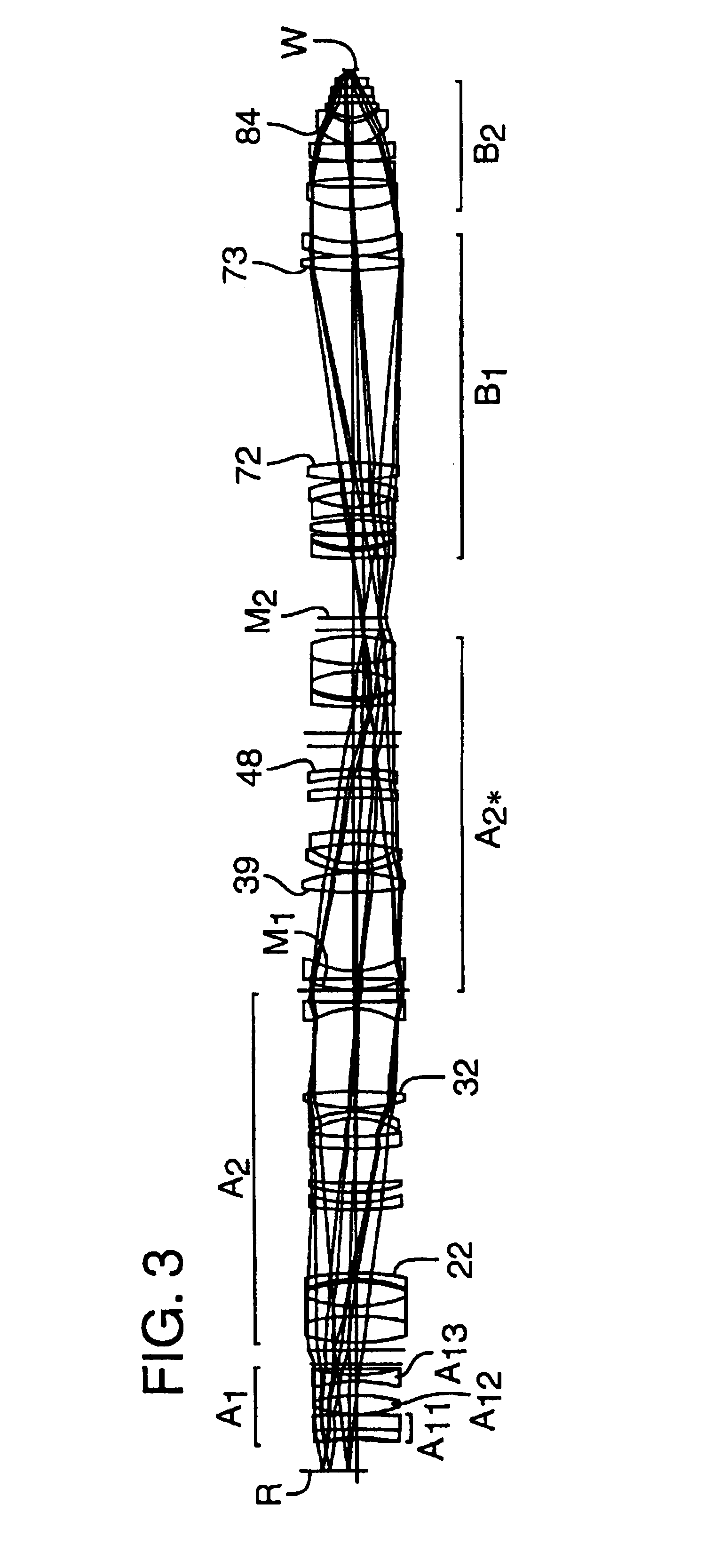

[0036]In order to describe the invention, a representation of a prior-art optical system is first described with reference to FIG. 7. A ray 102 from a location on a reticle R a distance d from an optical axis 100 is incident on a lens group A1. The lens group A1 comprises, in order from the reticle R and along the optical axis 100, a positive subgroup A12 and a n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com