Gas adsorbing element and method for forming same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

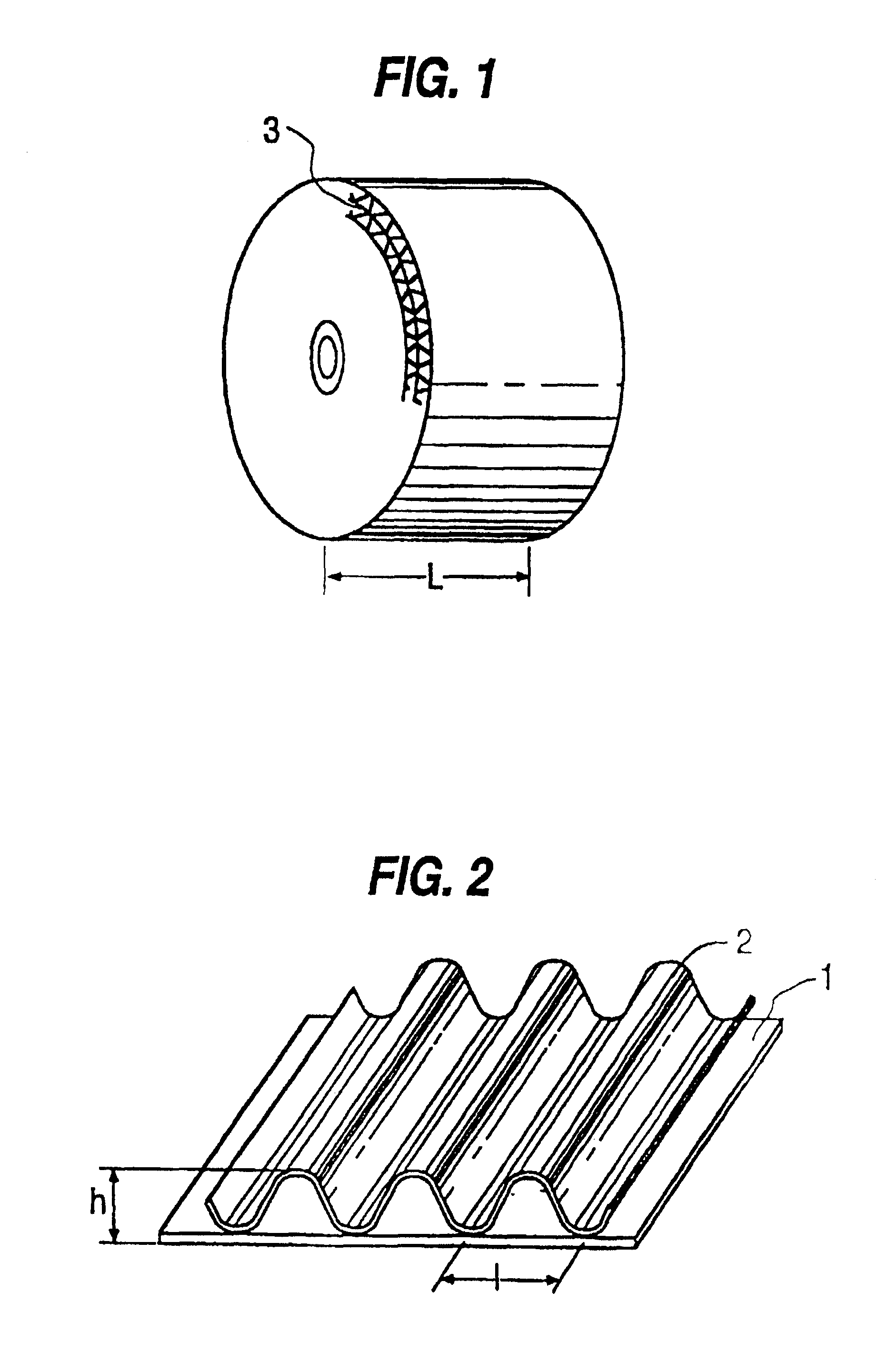

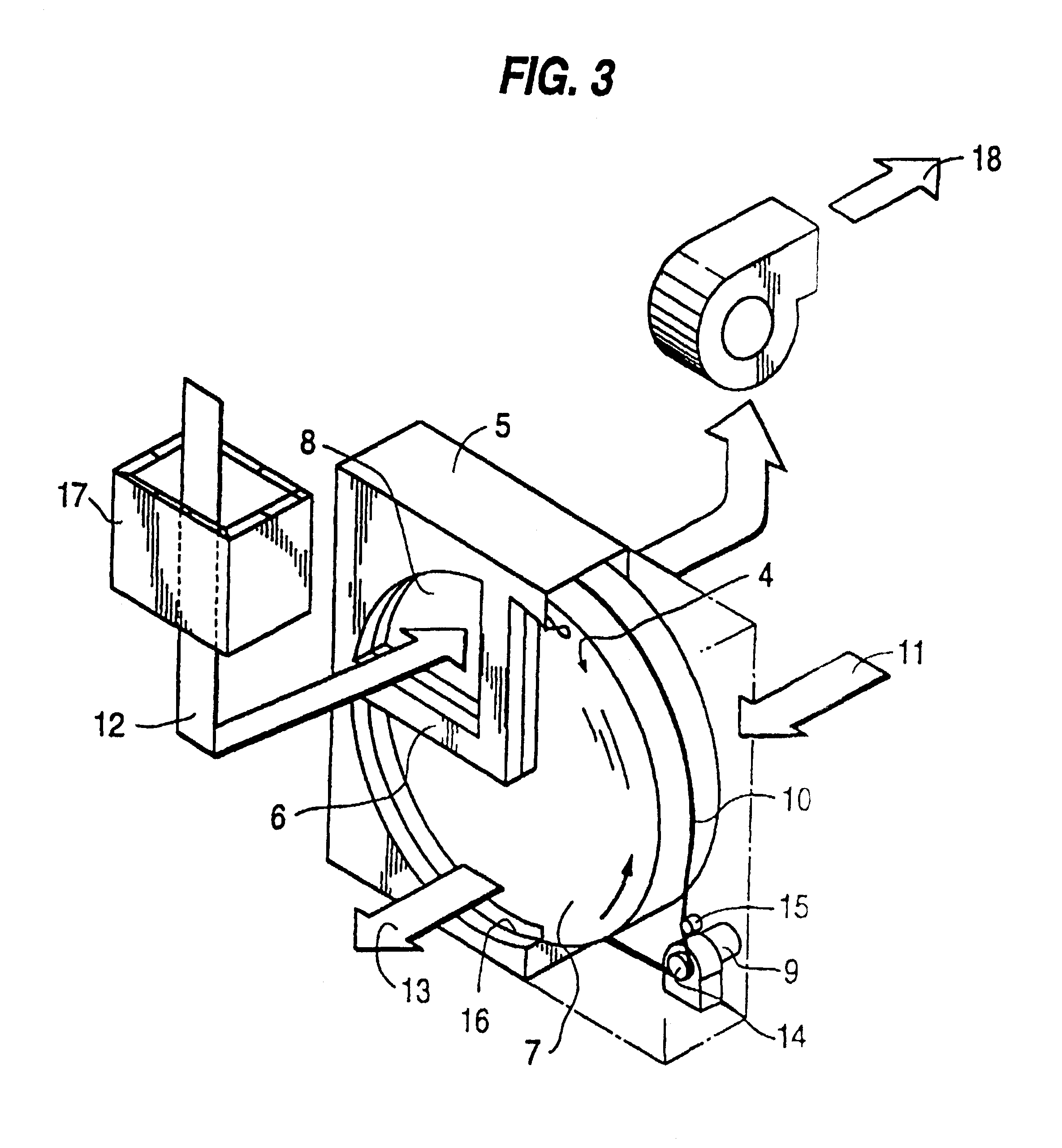

[0027]A small amount of organic synthetic fiber and a small amount of an inorganic or organic binder were added to ceramic fiber of silica alumina series to prepare low density paper having an apparent specific gravity of approximately 0.3˜0.45 (about 60-150 g / m2 weight) and a thickness of approximately 0.10˜0.30 mm. The paper was then corrugated so that it had a width of 400 mm, a wavelength of 3.4 mm and a wave height of 1.8 mm. Using an adhesive including a mixture of synthetic resin such as polyvinyl acetate and inorganic binder, a flat paper 1 and a corrugated paper 2 were bonded together at all ridged portions of the corrugated paper 2 as shown in FIG. 2 to obtain a single-faced corrugated sheet. The corrugated sheet was wound around a core material as shown in FIG. 1 and formed into a honeycomb-shaped laminate having a cylindrical shape having a diameter of 320 mm and having many small channels 3 penetrating from one end surface to the other. Zeolite of xNa2O.Al2O3.ySiO2.zH2O...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com