Phosphorescent organic light emitting devices

a light-emitting device and organic technology, applied in the direction of discharge tube luminescnet screen, other domestic articles, natural mineral layered products, etc., can solve the problem that it is not believed that organic materials can be used to produce efficient room temperature electrophosphorescence, and achieve the effect of preventing significant non-radiative energy loss to the host and significant non-radiative energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0101]A hole transporting layer (“HTL”) is first deposited onto the ITO (indium tin oxide) coated glass substrate. The HTL consists of 30 nm (300 Å) of NPD. A first electron transporting layer, which is also a blocking layer, consisting of TAZ, having a thickness of about 20 nm (200 Å) is deposited onto the HTL layer. The first electron transporting layer is doped with Ir(ppy)3. A second electron transport layer of Alq3 having a thickness of about 20 nm is deposited onto the first electron transporting layer. The device is finished by depositing a Mg—Ag electrode onto the second electron transporting layer. This Mg-Ag electrode has of thickness 100 nm. All of the depositions are carried out at a vacuum less than 5×10−5 Torr. The devices are tested in air, without packaging.

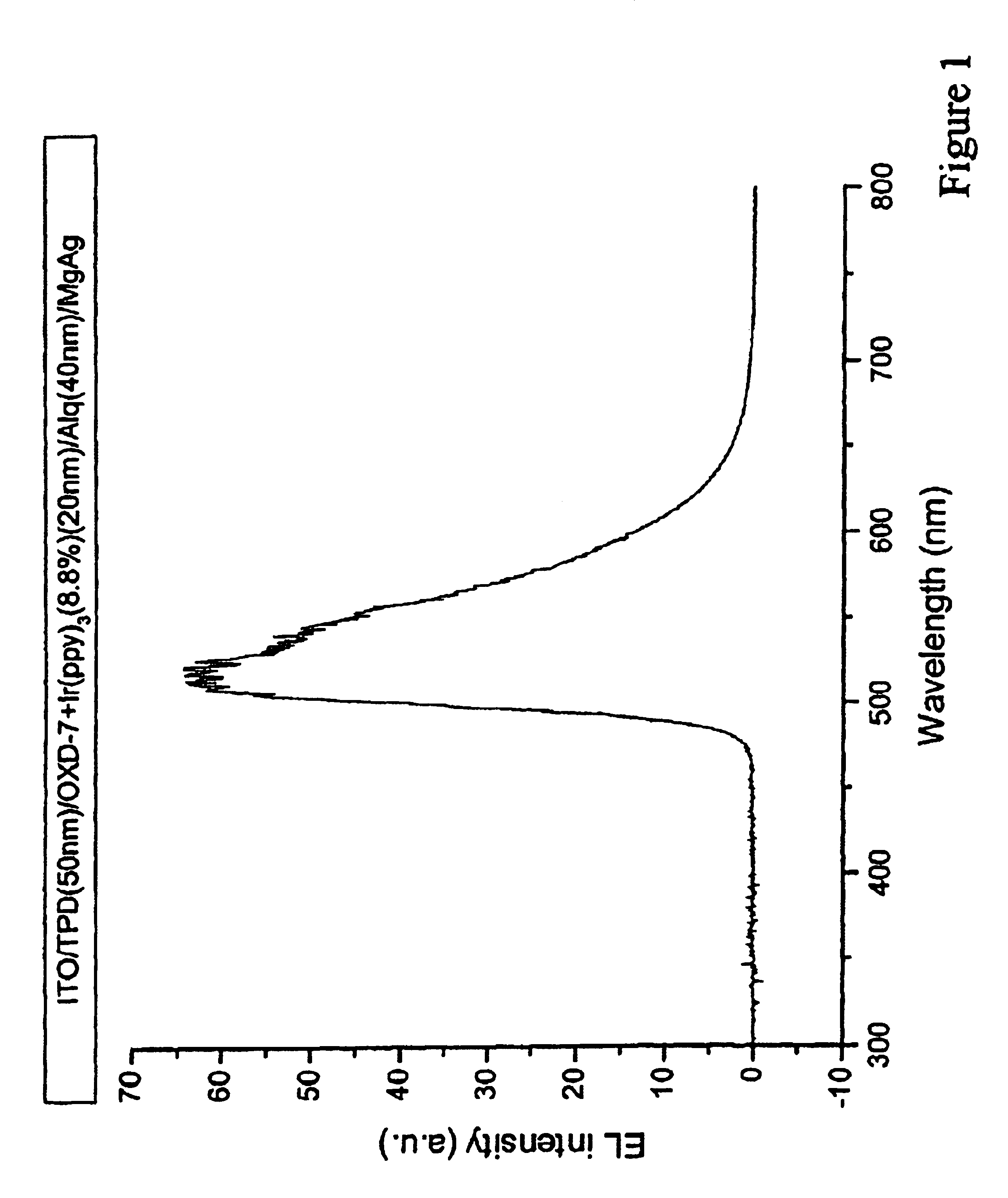

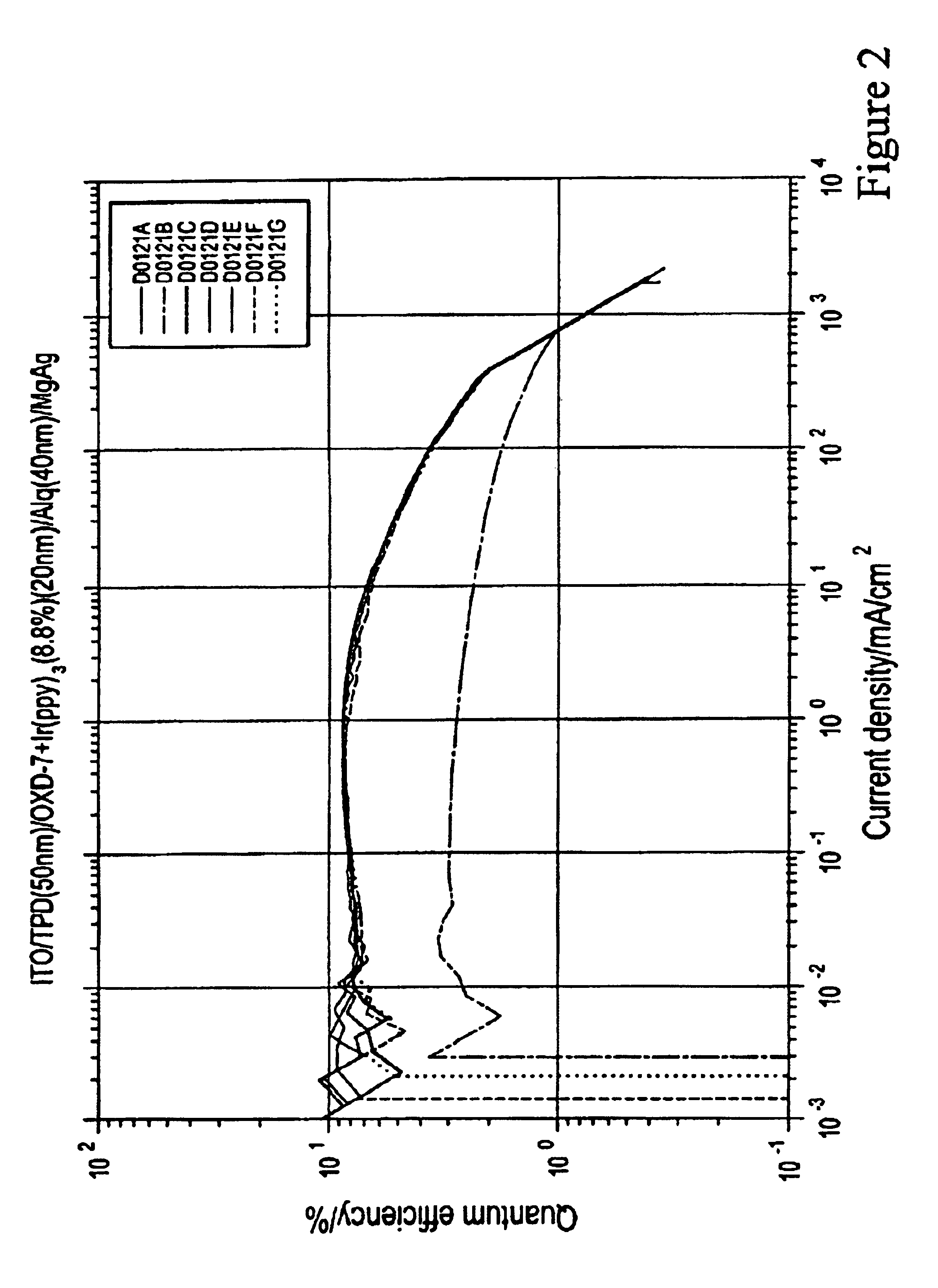

[0102]When a voltage is applied between the cathode and the anode, holes are injected from ITO to NPD and transported by the NPD layer, while electrons are injected from MgAg to Alq3 and transported through Alq3. ...

example 2

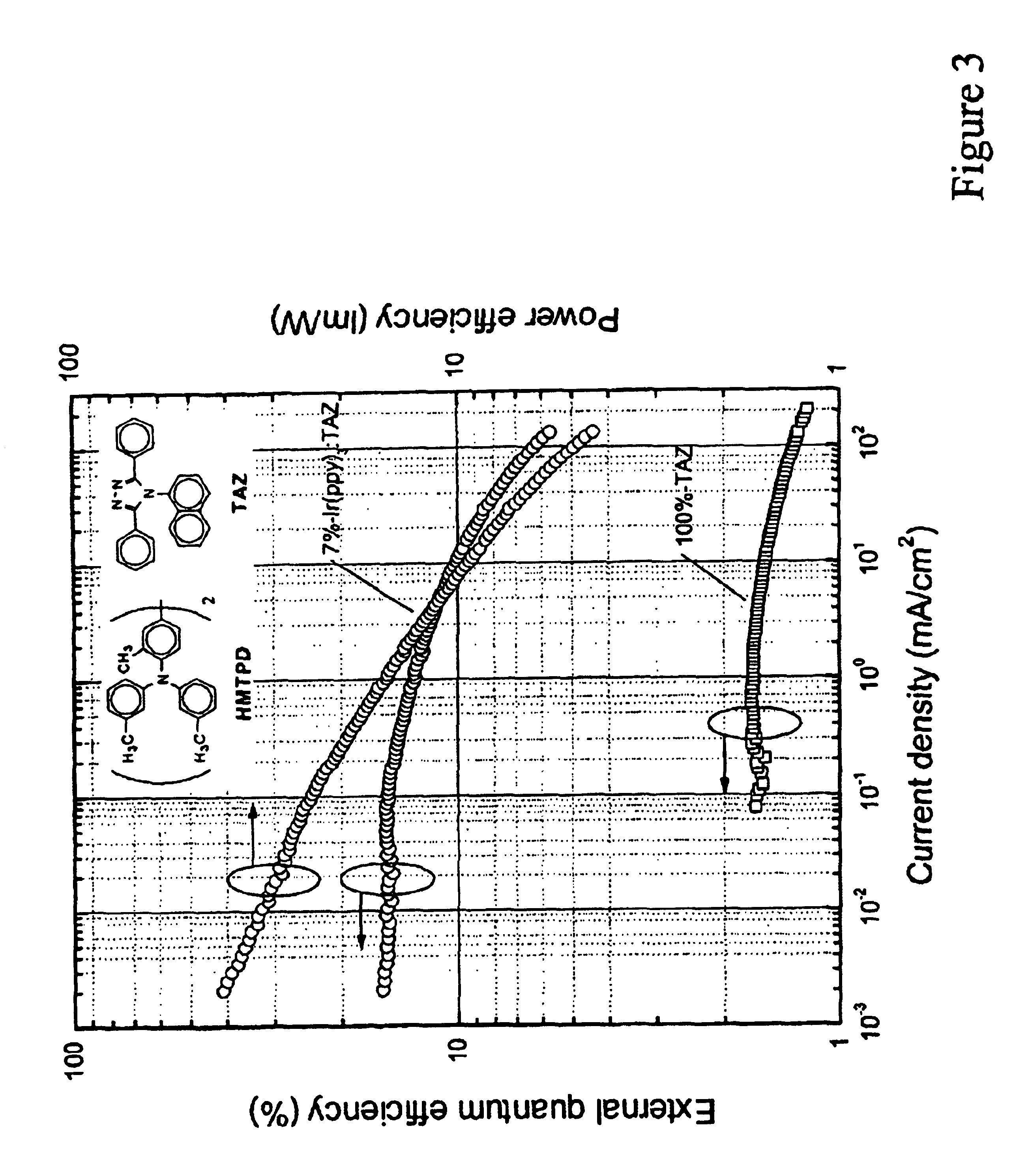

[0103]Organic layers were deposited by high vacuum (10−6 Torr) thermal evaporation onto a clean glass substrate precoated with an ITO layer. A 60 nm-thick film of 4,4′-bis[N,N′-(3-tolyl)amino]-3,3′-dimethylbiphenyl (HMTPD) serves as the HTL. Next a 25 nm-thick EML consisting of 6% to 8% Ir(ppy)3 is doped into various electron transporting hosts via thermal co-deposition. A 50 nm-thick layer of the electron transport material tris-(8-hydroxyquinoline) aluminum (Alq3) is used to transport and inject electrons into the EML. A shadow mask with 1 mm-diameter openings was used to define the cathode consisting of a 150 nm-thick magnesium silver (Mg—Ag) layer, with a 20 nm-thick Ag cap. Alternatively, the cathode consisted of a 100 nm-thick layer of aluminum-0.56wt % lithium.

[0104]Current density (J) versus voltage (V) measurements were obtained using a semiconductor parameter analyzer, with the luminance (L) obtained by placing the OLEDs directly onto the surface of a calibrated silicon ph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transparency | aaaaa | aaaaa |

| transparency | aaaaa | aaaaa |

| energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com