Self humidifying film electrode and its preparing method

A membrane electrode and self-humidification technology, which is applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problem of low weight specific power and volume specific power of the stack, increase the chance of cross-diffusion of hydrogen and oxygen gas, and increase the size of the fuel cell. Problems such as system size and weight can be solved to achieve the effect of improving weight specific power and volume specific power, simplifying design and manufacturing process, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

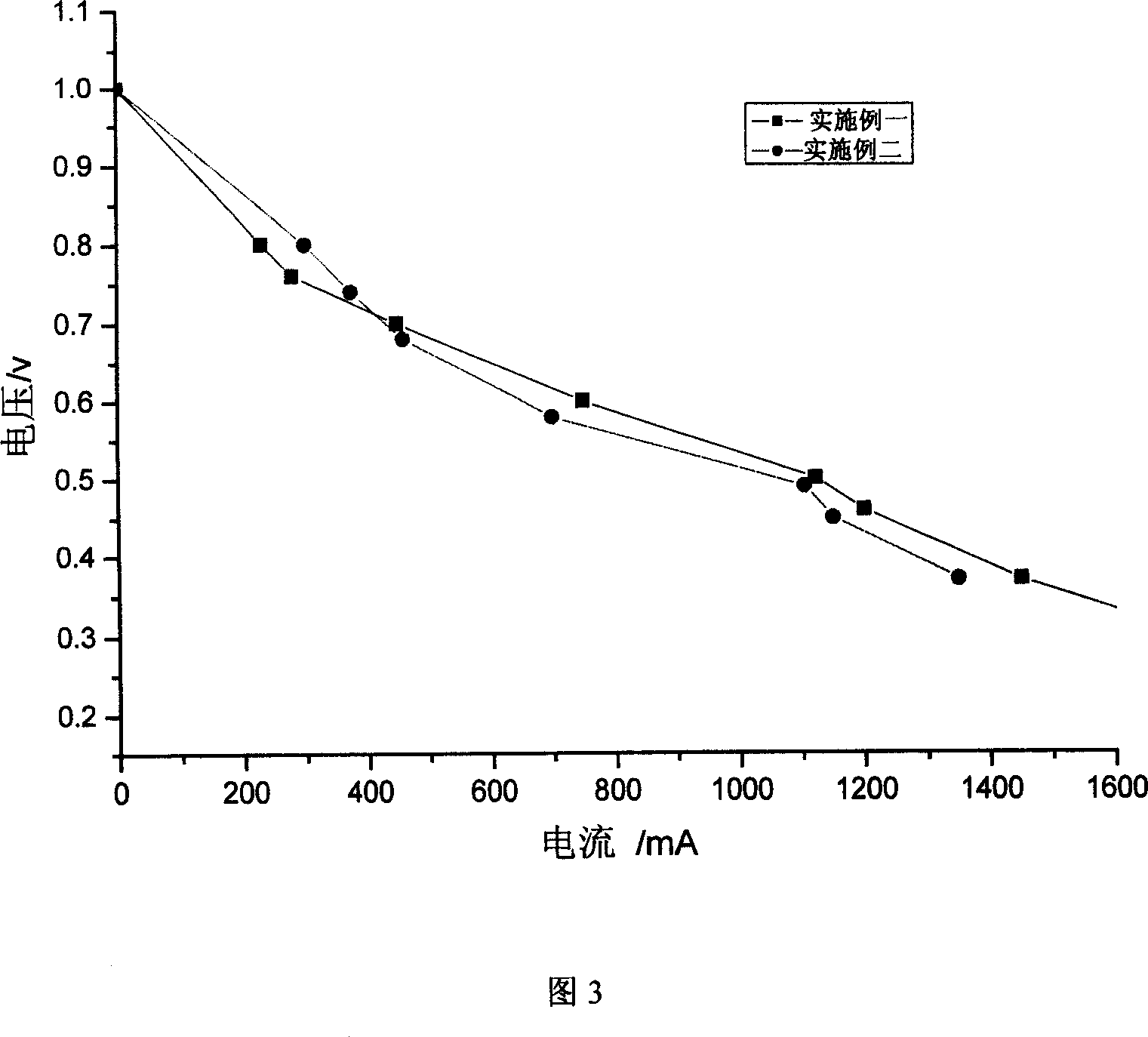

Embodiment 1

[0023] In the first step, the Nafion115 membrane is placed in 5% hydrogen peroxide, distilled water, 0.5mol / L sulfuric acid solution and distilled water for 0.5 hours to pretreat the membrane. A stainless steel clip is clamped and fixed to prevent the membrane from shrinking or curling in the air;

[0024] In the second step, the carbon-supported platinum catalyst (the product of E-TEK Company of the United States, the same below), the perfluorosulfonic acid polymer (the Nafion solution with a mass percentage concentration of 5% of the product of Dupont Company of the United States, the same below), SiO 2 , The mixture of isopropanol and distilled water is uniformly mixed according to the mass ratio of 10:2:1:100, dispersed and mixed into ink by ultrasonic vibration, and coated on one side of the film, the loading of Pt is 0.6mg / cm 2 , and then put the film in an oven and bake it at 80°C for 40 minutes to prepare a hydrophilic hydrogen electrode;

[0025] The third step is to...

Embodiment 2

[0029]In the first step, the Nafion112 membrane is placed in 5% hydrogen peroxide, distilled water, 0.8mol / L sulfuric acid solution and distilled water and boiled for 45 minutes respectively to pretreat the membrane, and use the pretreated proton exchange membrane with Four stainless steel clips are clamped and fixed to prevent the membrane from shrinking or curling in the air;

[0030] In the second step, the carbon-supported platinum catalyst, perfluorosulfonic acid polymer, TiO 2 The mixture of glycerin, ethanol and distilled water is uniformly mixed at a mass ratio of 10:3:2:150, dispersed and mixed into ink by ultrasonic vibration, and coated on one side of the film, with a Pt loading of 0.4mg / cm 2 , and then put the film in an oven and bake it at 100°C for 30 minutes to prepare a hydrophilic hydrogen electrode;

[0031] The third step is to uniformly mix the mixture of carbon-supported platinum catalyst, perfluorosulfonic acid polymer, PTFE, ethanol and distilled water ...

Embodiment 3

[0035] In the first step, the Nafion117 membrane is placed in 3% hydrogen peroxide, distilled water, 1.0mol / L sulfuric acid solution and distilled water and boiled for 1 hour each to pretreat the membrane, and the pretreated proton exchange membrane Clamp and fix with four stainless steel clips to prevent the membrane from shrinking or curling in the air;

[0036] In the second step, the carbon-supported platinum catalyst, the perfluorosulfonic acid polymer, the mixture of succinic acid and propanesulfonic acid, and acetonitrile are uniformly mixed according to the mass ratio of 10:4:3:200, and the ink is mixed by ultrasonic vibration. On one side of the membrane, the Pt loading was 1.0 mg / cm 2 , and then put the film in an oven and bake it at 60°C for 60 minutes to prepare a hydrophilic hydrogen electrode;

[0037] In the third step, the carbon-supported platinum catalyst, perfluorosulfonic acid polymer, polysiloxane, and acetonitrile were uniformly mixed in a mass ratio of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com