Method and device for preparing p-type zinc oxide crystal film by doping phosphorus

A zinc oxide, p-type technology, applied in semiconductor devices, gaseous chemical plating, semiconductor/solid-state device manufacturing, etc., can solve the problem of low industrial utilization value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

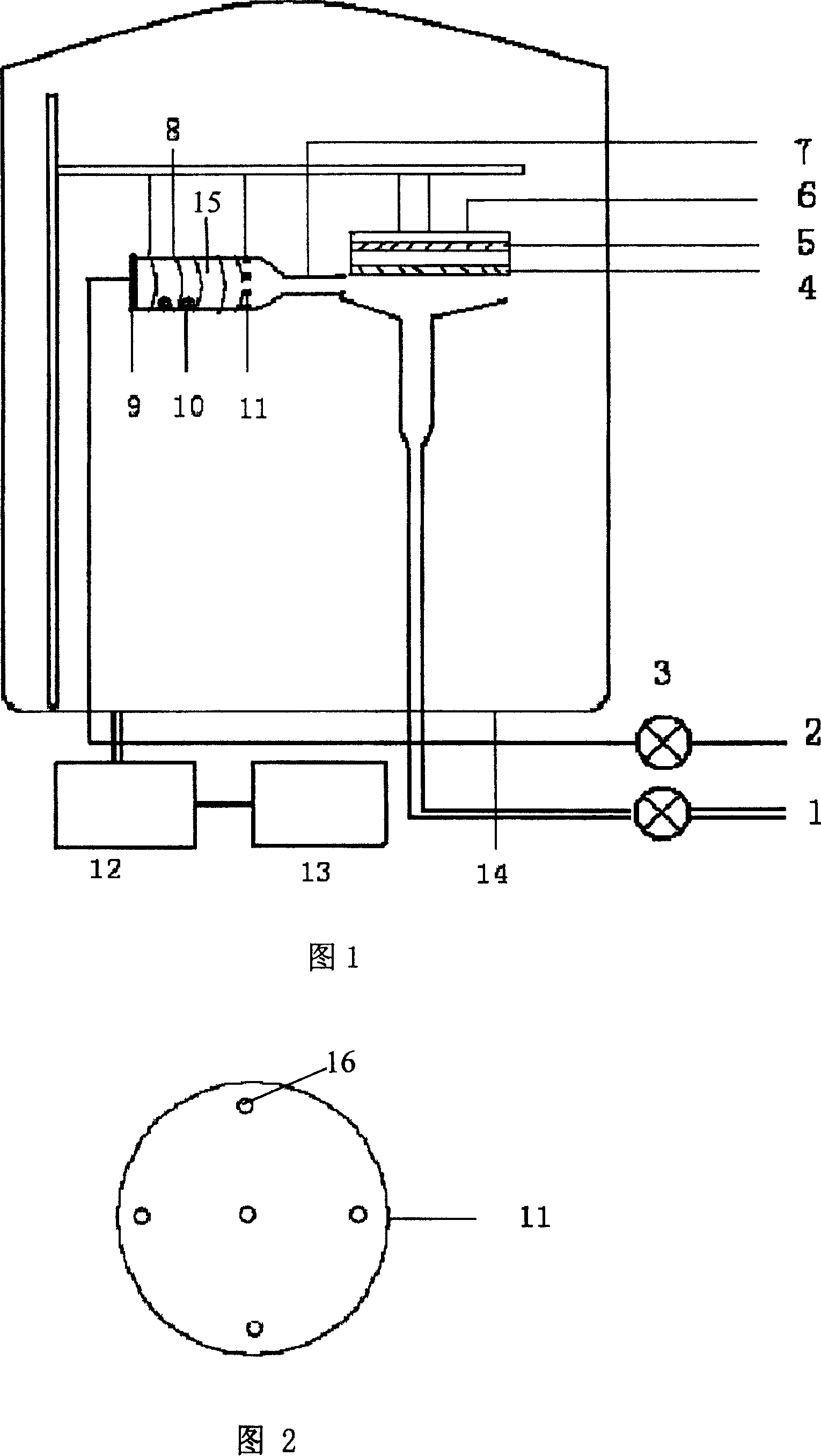

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific examples.

[0020] With reference to Fig. 1, the device for preparing p-type zinc oxide crystalline thin film by doping phosphorus of the present invention comprises growth chamber 14, growth chamber and molecular pump 12, mechanical pump 13, organic zinc source carrier gas inlet pipeline 1, oxygen source gas inlet pipe Road 2 is connected to each other, flow controller 3 is respectively arranged on organic zinc source carrier gas inlet pipeline 1 and oxygen source gas inlet pipeline 2, substrate heater 5, sample holder 6 and thermal evaporator 15 are arranged in the growth chamber, thermal evaporation The device includes a quartz tube 7, the inlet of the quartz tube is connected to the oxygen source gas inlet line 2 through a valve 9, and the outlet of the quartz tube is in the reaction zone. Generally, the outlet end of the quartz tube is flat to ensure the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com