4-nor-amyl diphenic acid-3-fluor-4-cyan phenol ester production process

A technology of n-pentyl bibenzoic acid and pentyl bibenzoic acid is applied in the directions of chemical instruments and methods, preparation of carboxylic acid nitrile, preparation of organic compounds, etc. The effect of promoting application prospects, reducing production costs and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

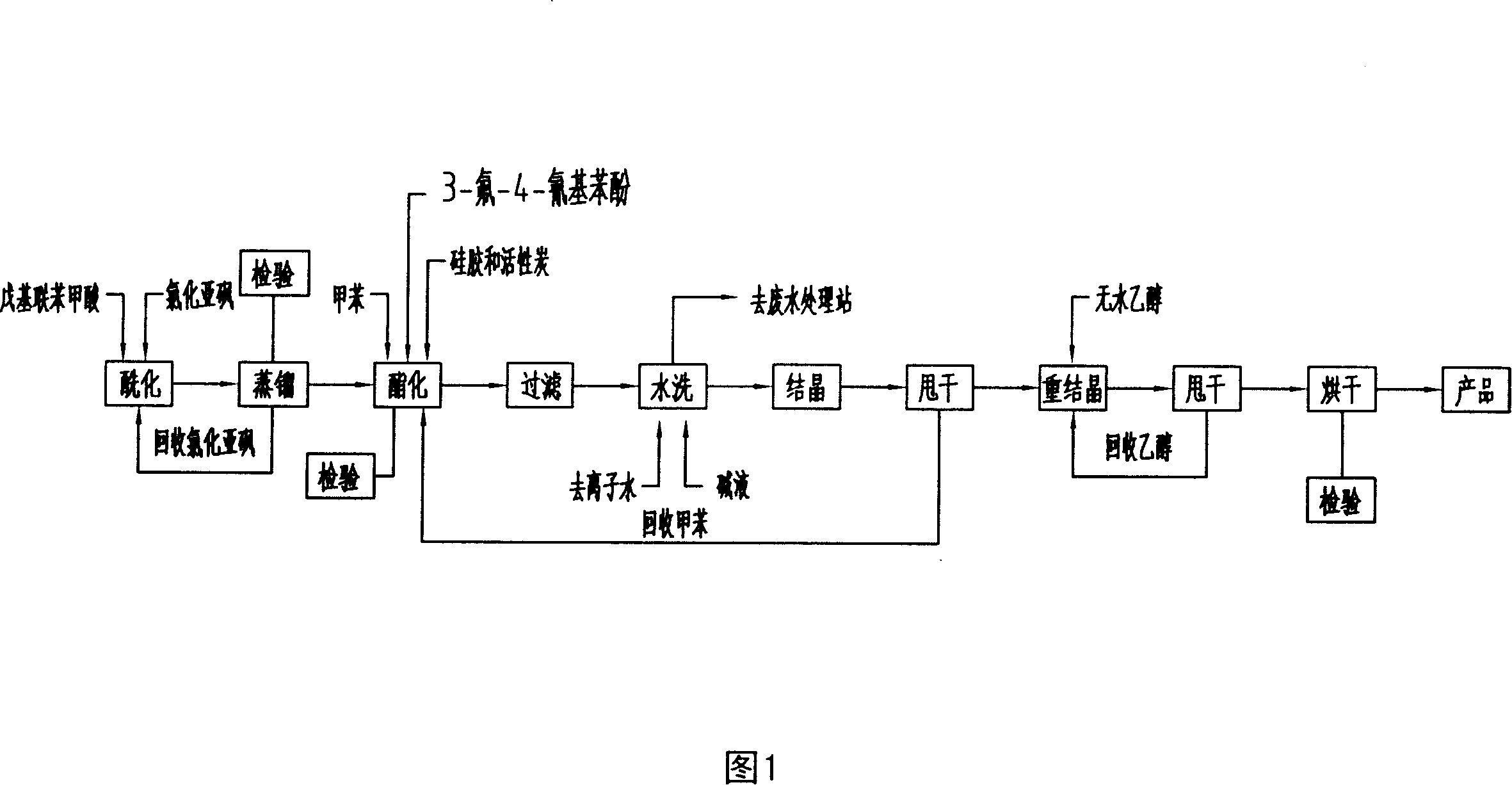

[0020] Example 1 Production process of 4-n-pentylbibenzoic acid-3-fluoro-4-cyanophenol ester

[0021] (1) Raw materials

[0022] Raw material name Specification index, grade Production unit

[0023] Pentyldibenzoic acid White crystal, melting point ≥ 101.0℃, industrial grade Shijiazhuang Chemical Reagent Co., Ltd.

[0024] Thionyl chloride Yellow-green transparent liquid, industrial grade Changzhou Henglin Chemical Factory

[0025] 3-Fluoro-4-cyanophenol white crystal, melting point≥125℃, industrial grade Shijiazhuang Chemical Reagent Co., Ltd.

[0026] Toluene Colorless transparent liquid, water content ≤0.1%, industrial grade Nanjing Chemical Reagent Co., Ltd.

[0027] Sodium hydroxide White flaky solid, industrial grade; Jiangsu Thorpe Group Co., Ltd.

[0028] Absolute Ethanol Colorless transparent liquid, purity ≥ 995%, industrial grade Nanjing Chemical Reagent Co., Ltd.

[0029] (2) Production equipment

[0030] Equipment name Specification model Quantity Manufactur...

Embodiment 2

[0045] Example 2 Production process of 4-n-pentylbibenzoic acid-3-fluoro-4-cyanophenol ester

[0046] The main raw material specifications, production equipment and the molar ratio of the main raw materials pentyl biphenylformic acid, thionyl chloride, 3-fluoro-4-cyanophenol, toluene, sodium hydroxide, and absolute ethanol are the same as in Example 1 ;

[0047] In the production process, when pentyl bibenzoyl chloride and 3-fluoro-4-cyanophenol are esterified and 3-fluoro-4-cyanophenol is added, silica gel and activated carbon are also added at the same time, and the amount of silica gel added is 1kg. Activated carbon addition is 3kg. The quality of the product is improved through the adsorption of impurities in the material by silica gel and the decolorization of the material by activated carbon.

Embodiment 3

[0048] Example 3 Production process of 4-n-pentylbibenzoic acid-3-fluoro-4-cyanophenol ester

[0049] The main raw material specifications, production equipment and the molar ratio of the main raw materials pentyldiphenylformic acid, thionyl chloride, 3-fluoro-4-cyanophenol, toluene, sodium hydroxide, and absolute ethanol are the same as in Example 1 ;

[0050] In the production process, pentyl bibenzoyl chloride and 3-fluoro-4-cyanophenol undergo esterification reaction. When adding 3-fluoro-4-cyanophenol, silica gel and activated carbon are also added at the same time. The amount of silica gel added is 2kg of activated carbon. Addition amount is 4kg. The quality of the product is improved through the adsorption of impurities in the material by silica gel and the decolorization of the material by activated carbon.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com