Method for extracting metal copper from electronical wastes

An electronic waste and electrowinning technology, applied in the improvement of process efficiency, photographic technology, instruments, etc., can solve the problems of high processing cost, low copper recovery rate and grade, and high corrosiveness, and achieve high recovery rate and grade. , the treatment conditions are not harsh, the effect of low treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

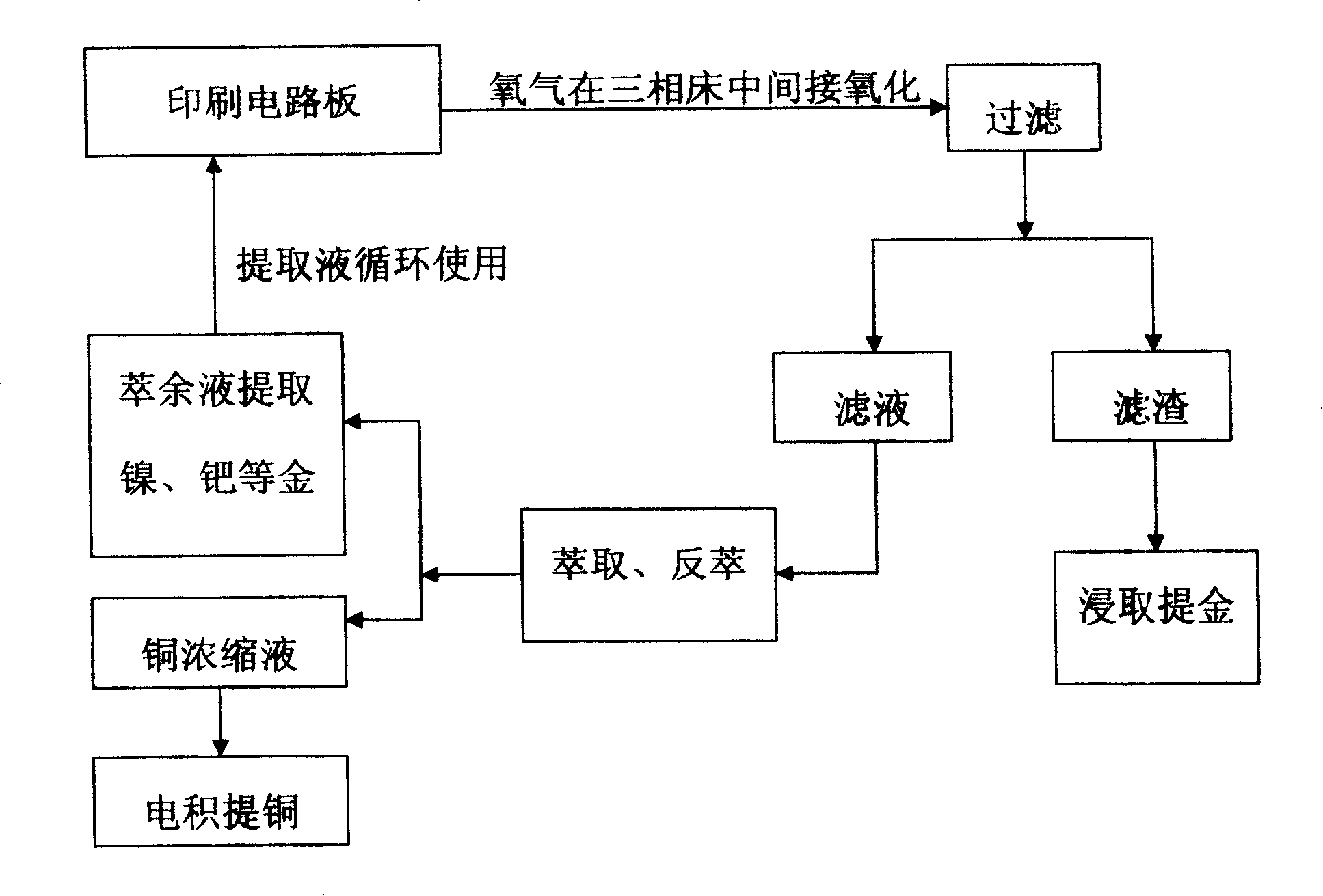

Method used

Image

Examples

Embodiment 1

[0043] Put the crushed printed circuit board into the three-phase bed, then add 5mol / L oxygen carrier, the weight ratio of the two is 1:10, adjust the pH value of the solution with sulfuric acid to be greater than 1.0, and use a high-pressure pump to press oxygen into the three-phase bed bed, and then the reactant was heated to 60° C., and reacted for 6 hours. When the printed circuit board was completely oxidized, the filtrate was obtained by filtration. Under room temperature conditions, the extractant and the filtrate are mixed, the ratio (O / A) is 2: 1, the concentration of the extractant is 30%, the pH value is adjusted to 2.0 with mineral acid, and the set stirring speed is 910r / min, the stirrer stirs the mixed solution, through the secondary extraction and the primary stripping, the time of each stage is 3min, and the copper sulfate solution 40g / L that meets the electrowinning requirements can be obtained. Then put the copper sulfate solution into the electrolytic cell ...

Embodiment 2

[0045]Put the pulverized printed circuit board into the three-phase bed, stir evenly, then add 2.5mol / L of oxygen carrier, the weight ratio of the two is 1:1, adjust the pH value of the solution with sulfuric acid to be greater than 1.0, and use a high-pressure pump to transfer oxygen Air pressure into the three-phase bed, and then the reactant was heated to 90 ° C, reacted for 4 hours, when the printed circuit board was completely oxidized, filtered to obtain the filtrate. Under room temperature conditions, the extractant and the filtrate are mixed, the ratio (O / A) is 10:1, the concentration of the extractant is 10%, the pH value is adjusted to 1.0 with mineral acid, and the set stirring speed is 100r / min, the stirrer stirs the mixed solution, through the secondary extraction and the primary stripping, the time of each stage is 1min, and the copper sulfate solution 45g / L that meets the electrowinning requirements can be obtained. Then put the copper sulfate solution into the...

Embodiment 3

[0047] Put the pulverized printed circuit board into the three-phase bed, then add 0.01mol / L oxygen carrier, adjust the pH value of the solution to be greater than 1.0 with sulfuric acid, press oxygen into the three-phase bed with a high-pressure pump, and then heat the reactants to 80°C, react for 4 hours, when the printed circuit board is completely oxidized, filter to obtain the filtrate. Under room temperature conditions, the extractant and the filtrate are mixed, the ratio (O / A) is 1: 1, the concentration of the extractant is 100%, the pH value is adjusted to 3.5 with mineral acid, and the set stirring speed is 1300r / min, the stirrer stirs the mixed solution, through the secondary extraction and the primary stripping, the time of each stage is 10min, and the copper sulfate solution 50g / L that meets the electrowinning requirements can be obtained. Then put the copper sulfate solution into the electrolytic cell for electrowinning, the temperature of the cell is 60°C, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com