Preparation technique for soft-magnetic manganese-zinc ferrite powder

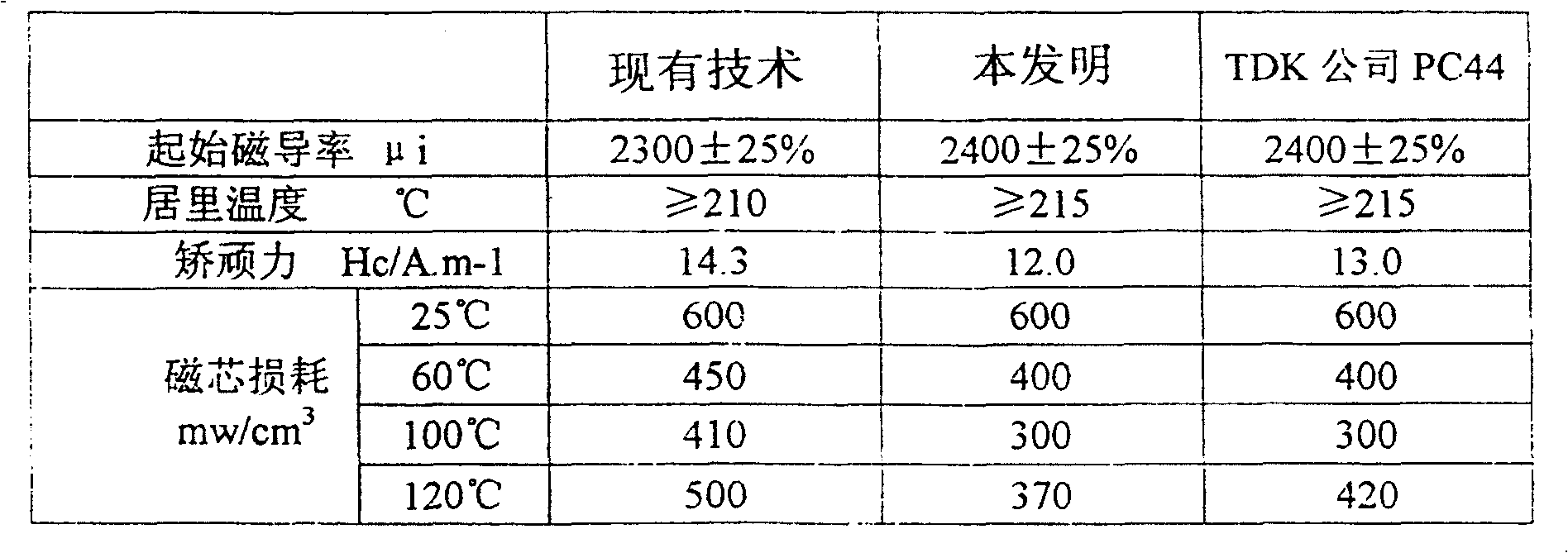

A technology of manganese zinc ferrite and ferrite powder, which is applied in the field of production technology of ferrite magnetic materials, can solve the requirements of miniaturization, light weight and high reliability of magnetic materials, ferrite magnetic materials The initial magnetic permeability is low, it is difficult to meet the environmental protection requirements, etc., to achieve the effect of reducing the secondary sanding time, small power loss, and reducing dust pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiments of the present invention are as follows: the production technology of soft magnetic manganese zinc ferrite powder, its production technology is carried out according to the following steps:

[0018] a. Put the raw materials ferric oxide, zinc oxide, and manganese tetraoxide (or manganese carbonate) into a sand mill with deionized water, and mix the raw materials with the steel ball at the lower end of the sand mill through the rotation of the stirring rod , Grinding. Then the ground slurry is subjected to spray granulation, and its average particle size is controlled at about 2.5 μm;

[0019] b. Pre-burn the spray granulated material, and then put the pre-fired material into the vibrating ball mill. The steel balls in the machine vibrate and grind the pre-fired material during the vibration process. The pre-fired material with a fineness below 1.5μm will pass through the sieve leaked;

[0020] c. The fine material after vibratory ball milling is subjected ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com