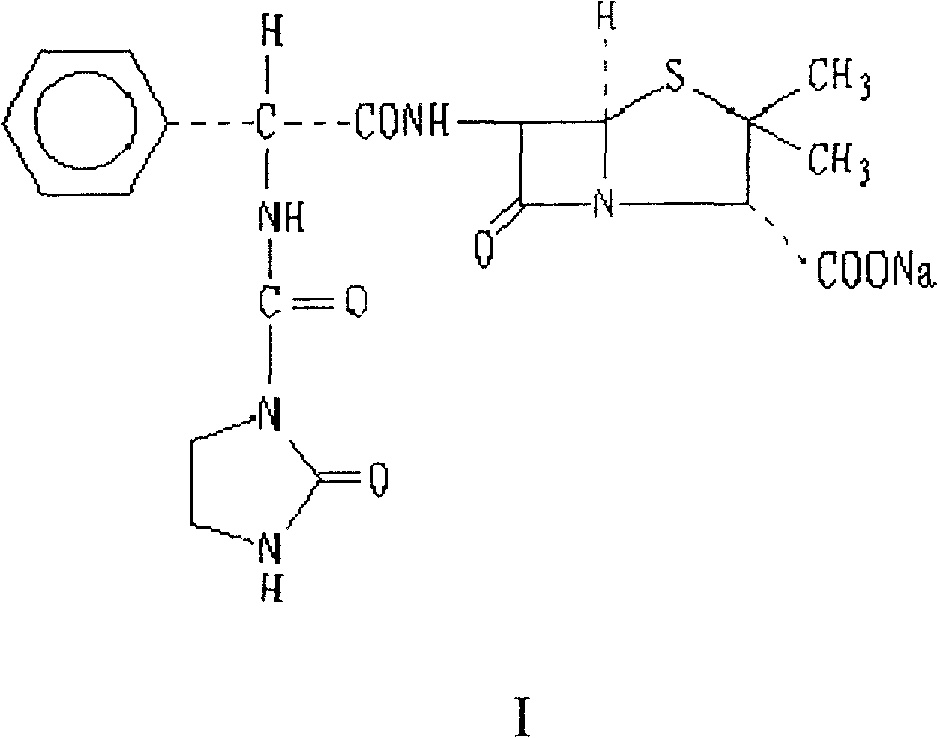

Process for preparing azlocillin sodium

A technology of azlocillin sodium and azlocillin, applied in the directions of organic chemistry, antibacterial drugs, etc., can solve the problems of high residual ethyl acetate, high qualified products, complicated production, etc., and achieve obvious economic and social benefits, Low production cost and good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

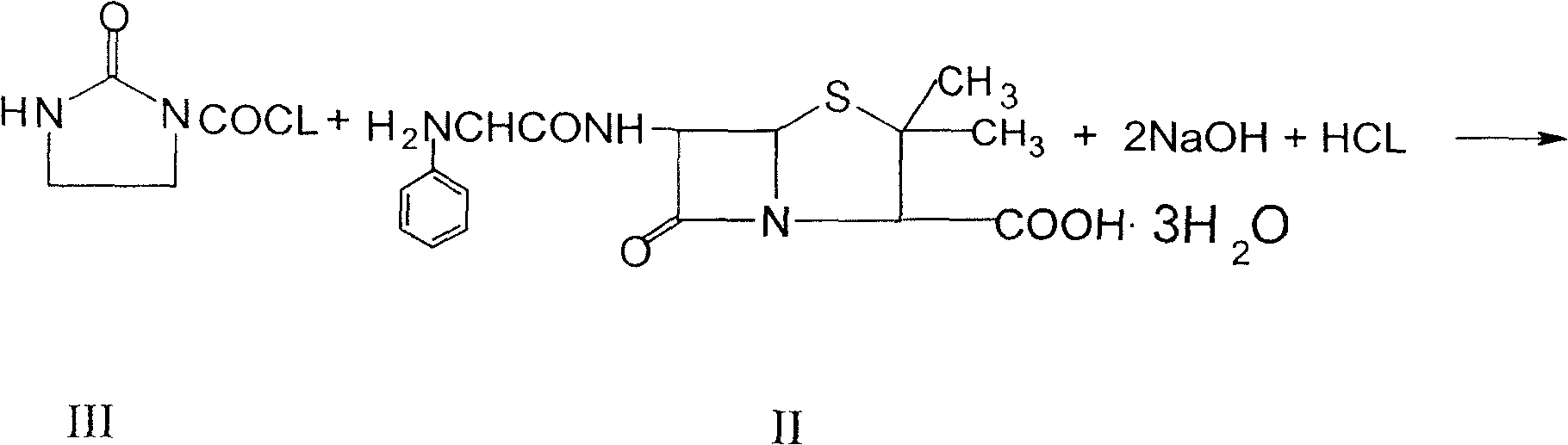

Method used

Image

Examples

Embodiment 1

[0041] Preparation of Azlocillin:

[0042] Add a certain amount of 50Kg of purified water and 10Kg of ampicillin into the cleaned reaction pot, stir, cool down, and then slowly add 2N sodium hydroxide solution until all the ampicillin is dissolved. Slowly add 4.0Kg of imidazole chloride, control the pH value of the solution in the tank between 6.0-7.5, filter with suction, add 40Kg of acetone to the filtrate, and acidify it to 2.0-3.0 with hydrochloric acid. Centrifuge, wash twice with purified water first and then with acetone, separate and dry, wait for inspection, and pack. (Yield 92.25%)

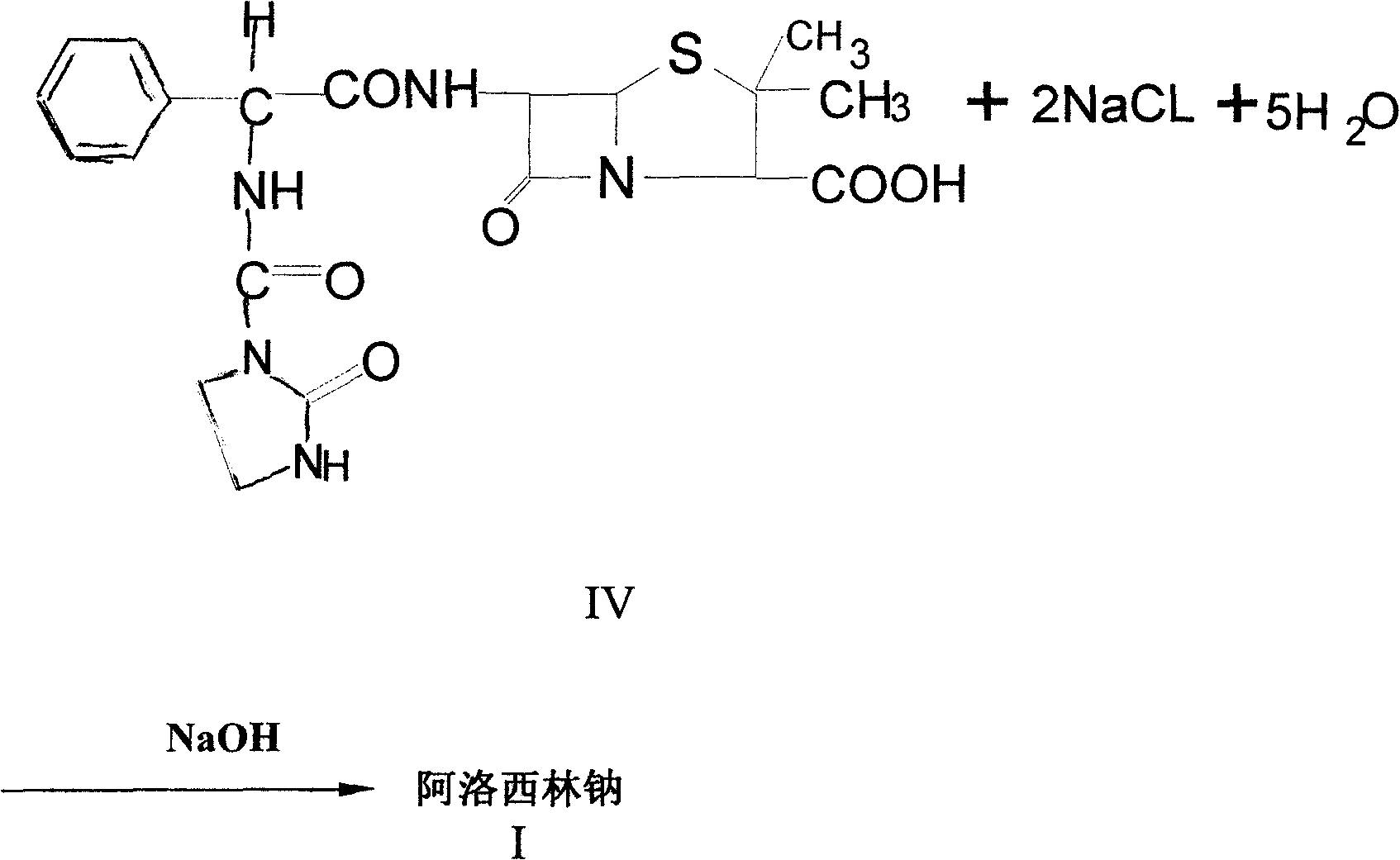

[0043] Preparation of Azlocillin Sodium

[0044] Inhale 40Kg of water for injection into the batching tank, add 10Kg of azlocillin, stir for about 10 minutes, start to add 2N sodium hydroxide solution dropwise until the material liquid is completely clear and the pH value is between 6.8 and 8.5, which is the end point, add activated carbon, and continue stirring Decolorize for half an...

Embodiment 2

[0047] Preparation of azlocillin

[0048] Add a certain amount of 50Kg of purified water and 10Kg of ampicillin into the cleaned reaction pot, stir, then slowly add 2N sodium hydroxide solution until all the ampicillin is dissolved. Slowly add 4.0Kg of imidazole chloride, control the pH value of the solution in the tank between 6.0-7.5, filter with suction, add 60Kg of acetone to the filtrate, and acidify it to 2.0-3.0 with hydrochloric acid. Centrifuge, wash twice with purified water first and then with acetone, separate and dry, wait for inspection, and pack. (Yield 92.81%)

[0049] Preparation of Azlocillin Sodium

[0050] Inhale 60Kg of water for injection into the batching tank, add 10Kg of azlocillin, stir for about 10 minutes, start adding 2N sodium hydroxide solution dropwise until the material liquid is completely clear and the pH value is between 6.8 and 8.5, which is the end point, add activated carbon, and continue stirring Decolorize for half an hour, decarboni...

Embodiment 3

[0053] Preparation of azlocillin

[0054]Add a certain amount of 50Kg of purified water and 10Kg of ampicillin into the cleaned reaction pot, stir, cool down, and then slowly add 2N sodium hydroxide solution until all the ampicillin is dissolved. Slowly add 4.0Kg of imidazolyl chloride, control the pH value of the solution in the tank between 6.0-7.5, filter with suction, add 40Kg of ethanol to the filtrate, and acidify it to 2.0-3.0 with hydrochloric acid. Centrifuge, first wash twice with purified water and then with ethanol, separate and dry, wait for inspection, and pack. (Yield 94.76%)

[0055] Preparation of Azlocillin Sodium

[0056] Inhale 50Kg of water for injection into the batching tank, add 10Kg of azlocillin, stir for about 10 minutes, start to add 2N sodium hydroxide solution dropwise until the material liquid is completely clear and the pH value is between 6.8 and 8.5, which is the end point, add activated carbon, and continue stirring Decolorize for half an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com