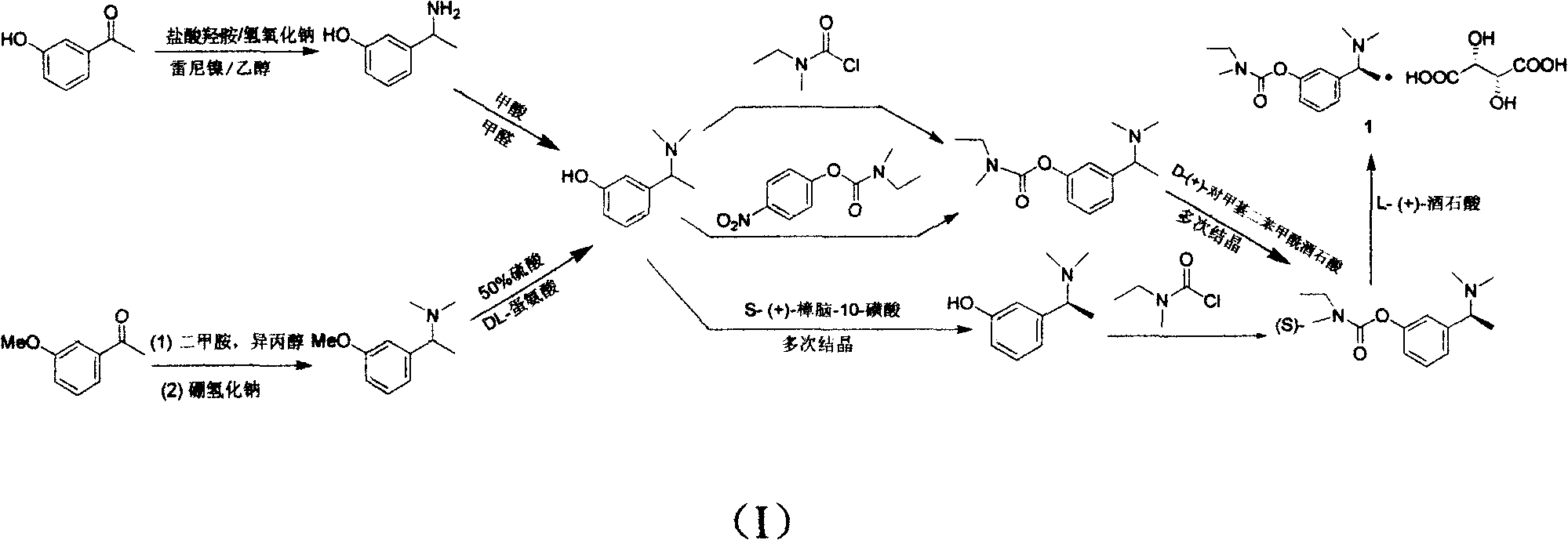

Method for synthesis of rivastigmine

A synthetic method, ethyl technology, applied in the field of anti-senile dementia drug rivastigmine, which can solve the problems of long synthetic route, high cost, and low yield, and achieve less reaction by-products, low cost, and good recovery yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

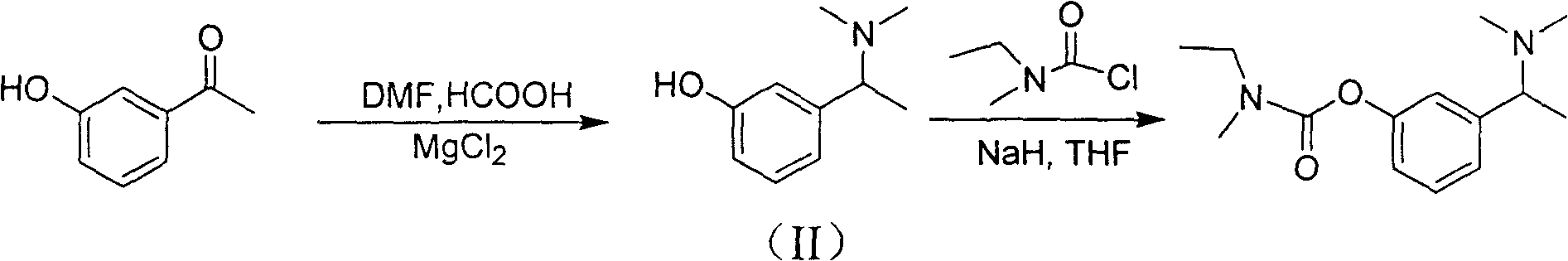

Embodiment 1

[0024] (1) Under ice-bath conditions, slowly add 33% dimethylamine aqueous solution (54.5g, 0.4mol) to a 250ml there-necked flask containing 88% formic acid (20.9g, 0.4mol), after adding, heat and distill , and about 46ml of water was evaporated to obtain the new ecological N,N-dimethylformamide (DMF). When the temperature drops below 100°C, add m-hydroxyacetophenone (13.6g, 0.1mol), formic acid (concentration 88%) (4.6g, 0.1mol), MgCl 2 ·6H 2 O (3 g, 0.015 mol). Directly raise the temperature to 170°C, heat the reaction for 5 hours, after the reaction is completed, pour the reaction solution into 80ml of water, wash the reaction bottle with about 5ml of water and combine them together, adjust the pH value to about 1-2 with concentrated hydrochloric acid, filter, and extract with ether , the ether phase was dried with anhydrous magnesium sulfate, and evaporated to dryness by rotary evaporation to obtain 6.47 g of m-hydroxyacetophenone as a solid raw material for recycling. ...

Embodiment 2

[0027] (1) In a 100ml three-necked flask, add m-hydroxyacetophenone (4g, 0.029mol), 88% formic acid (4ml, 0.093mol), N,N-dimethylformamide (DMF) (20ml, 0.26mol) . Heat to 155°C and reflux for 24 hours, adjust the pH value to about 1-2 with concentrated hydrochloric acid, filter, extract with ether, dry the ether phase with anhydrous magnesium sulfate, first remove the ether by ordinary distillation, and then remove excess DMF by distillation under reduced pressure to obtain a solid raw material m-Hydroxyacetophenone 2.55g. The aqueous phase was adjusted to pH 8.5 with sodium bicarbonate, extracted with ethyl acetate, anhydrous MgSO 4 Drying, rotary evaporation and concentration, the remaining raffinate was cooled, and the solid was precipitated, filtered, and vacuum-dried to obtain the product 3-(1-(dimethylamino)ethyl)phenol (0.65g, yield: 13.4%; recovery yield : 36.9%).

[0028] (2) With embodiment 1.

Embodiment 3

[0030] (1) Same as Example 1, in the 2000ml there-necked flask filled with 88% formic acid (418g, 8mol), slowly add 33% dimethylamine aqueous solution (1090g, 8mol), after adding, heat and distill, evaporate water, The new ecological N,N-dimethylformamide (DMF) was obtained. After being cooled to about 100°C, add m-hydroxyacetophenone (1.36g, 0.01mol), formic acid (88% concentration) (4.6g, 0.1mol), MgCl 2 ·6H 2 O (2 g, 0.01 mol). The temperature was directly raised to 170° C., and the reaction was heated for 5 hours. After the reaction was completed, excess DMF was distilled off under reduced pressure, and the residue was poured into 10 ml of water. Other operations are the same as in Example 1. 3-(1-(Dimethylamino)ethyl)phenol (0.7 g, yield: 42.4%; recovered yield: 79.0%) was obtained.

[0031] (2) With embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com