Process for preparing nanometer zinc oxide precursor

A nano-zinc oxide and precursor technology, applied in the direction of zinc oxide/zinc hydroxide, etc., can solve the problems of high cost, expensive equipment, difficult mass production, etc., and achieve the effect of low cost, easy control of conditions, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Add 4.0 g of anhydrous zinc chloride (30 mmol) into 10 mL of anhydrous methanol, stir until completely dissolved to form a saturated methanol solution A of zinc chloride; then add 10 mL of acetylacetone, and stir at room temperature for 0.5 to 24 h, Form colorless solution B; then add triethylamine dropwise to solution B while stirring to form colorless solution C, adjust the pH value of solution C to about 8, continue stirring for 2 hours; finally add colorless solution C to 10 times the solution volume In distilled water, crystals were precipitated immediately, left standing for 4 hours, suction filtered, washed with distilled water, and then dried at 60°C to obtain the nano-zinc oxide precursor of the present invention.

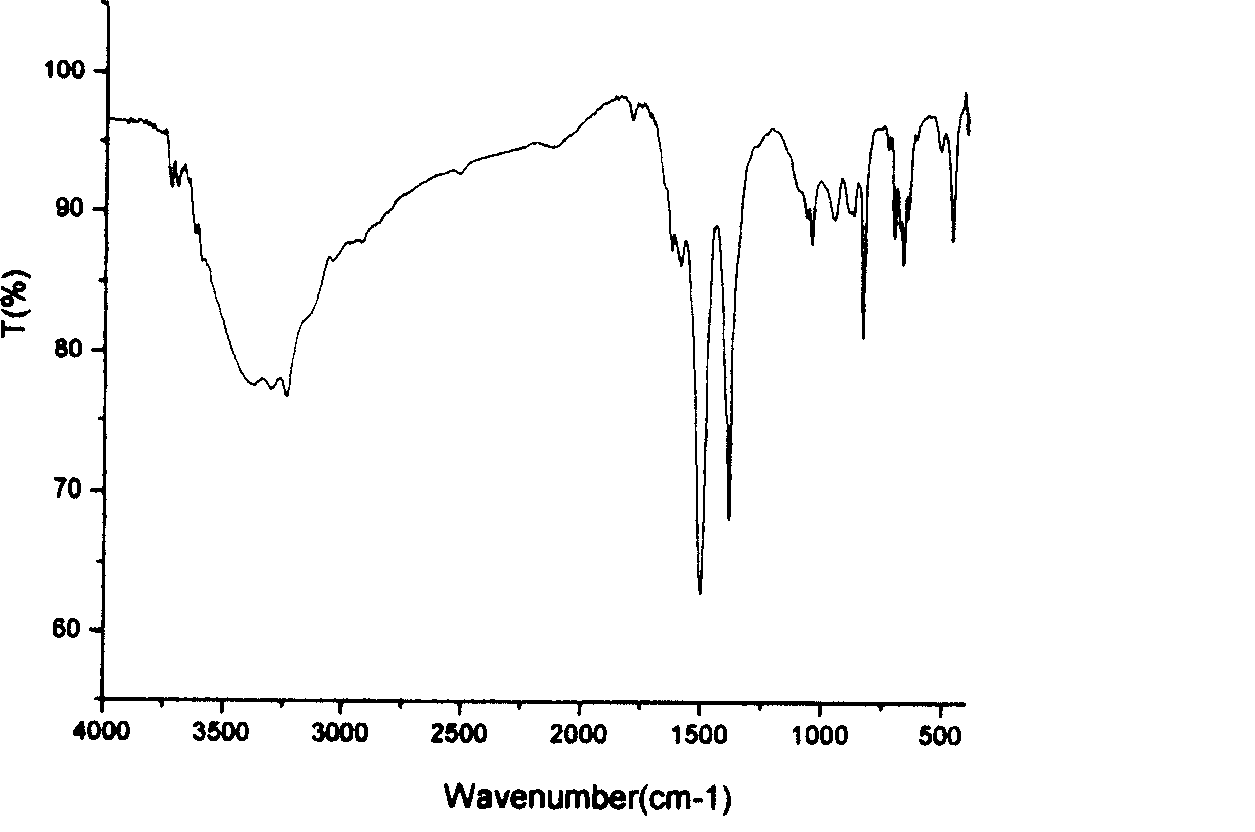

[0031] The infrared spectrum of the nano-zinc oxide precursor is as follows figure 1 shown.

[0032] Anneal the nano-zinc oxide precursor at 600°C for 4 hours to obtain a one-dimensional zinc oxide nanowire self-assembled by nanoparticles. The TEM ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com