Method for preparing self-antifouling sanitation cement product

A technology for finished products and cement, applied in the field of preparation of self-anti-fouling and cleaning cement products, can solve the problems of titanium oxide sol film formation and poor anti-fouling performance, etc., so as to solve the problem of poor performance and save the heat treatment process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

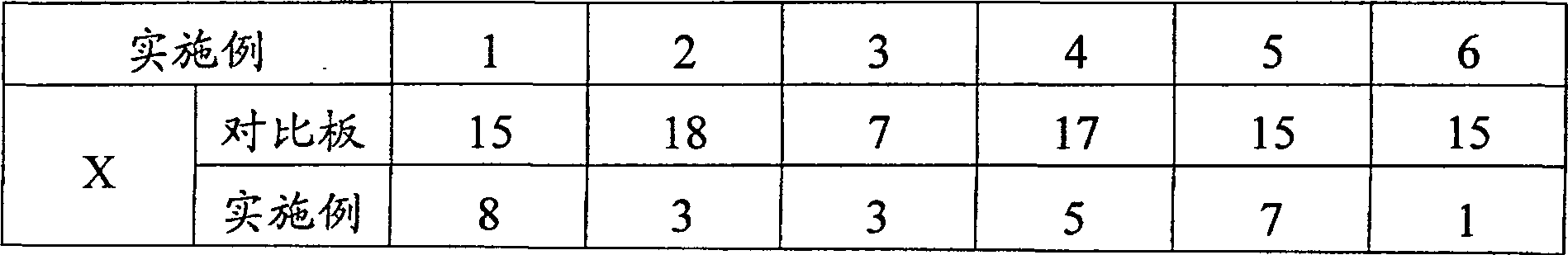

Examples

Embodiment 1

[0029] (1) Dissolve ferric nitrate and lanthanum nitrate (weight ratio 1:1) in distilled water, adjust the pH value of the solution to 0.1 with nitric acid, and prepare ferric nitrate and lanthanum nitrate solution, the weight ratio of distilled water to ferric nitrate and lanthanum nitrate is 1;

[0030] (2) Under stirring conditions, add butyl titanate to dehydrated ethanol for dilution, the mass ratio of dehydrated alcohol to titanium salt is 1, stir to obtain butyl titanate ethanol solution;

[0031] (3) Add butyl titanate ethanol solution dropwise to ferric nitrate and lanthanum nitrate solution in a water bath at 5°C. The mass ratio of ferric nitrate and lanthanum nitrate solution to butyl titanate ethanol solution is 50. After full reaction , standing for 5 hours to obtain anatase crystal titanium sol;

[0032] (4) Get the styrene-acrylic emulsion, pre-coat on the surface of the cement board, form a film, dry, and form an isolation layer;

[0033] (5) Take the anatase...

Embodiment 2

[0035] (1) Triethylamine is dissolved in deionized water, and the pH value of the solution is adjusted to 5 with hydrochloric acid to obtain triethylamine solution, and the mass ratio of deionized water to triethylamine is 500;

[0036] (2) under stirring condition, titanium tetrachloride is added in ethylene glycol and diluted, and the mass ratio of ethylene glycol and titanium tetrachloride is 10, stirs and makes titanium tetrachloride ethylene glycol solution;

[0037] (3) Add the titanium tetrachloride ethylene glycol solution dropwise to the triethylamine solution in a water bath at 95°C. The mass ratio of the triethylamine solution to the titanium tetrachloride ethylene glycol solution is 500. After fully reacting , and then left to stand for 1 hour to obtain anatase crystal titanium sol;

[0038] (4) Get the acrylic resin paint, pre-coat on the cement road surface, form a film, dry, and form the isolation layer;

[0039] (5) Take the anatase crystal titanium sol, spray...

Embodiment 3

[0041] (1) Dissolving ethyl orthosilicate in deionized water, while adjusting the pH value of the solution to 2.5 with sulfuric acid, the weight ratio of deionized water to ethyl orthosilicate is 1 to 80;

[0042] (2) under stirring condition, butyl titanate is added in isopropanol to dilute, and the mass ratio of isopropanol to butyl titanate is 3, stirs to obtain butyl titanate isopropanol solution;

[0043] (3) Add the butyl titanate isopropanol solution dropwise to the solution obtained in step (1), the mass ratio of the solution obtained in step (1) to the butyl titanate isopropanol solution is 100, at 35°C water bath temperature After fully reacting, leave it still for 20 hours to obtain anatase crystal titanium sol;

[0044] (4) Get the fluorocarbon resin coating, pre-coat on the cement brick surface, form a film, dry, and form an isolation layer;

[0045] (5) Take the anatase crystal titanium sol, cast it on the surface of the cement road brick coated with the fluoroc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com