Near-ultraviolet or ultraviolet excited semiconductor luminous material and its preparing method

A fluorescent material, yellow-green light technology, applied in the direction of luminescent materials, semiconductor/solid-state device manufacturing, semiconductor devices, etc., can solve the problems of unstable chemical and optical properties, difficult to control reaction conditions, expensive raw materials, etc., to achieve high chemical and optical The effect of stability, easy operation of production process, and improvement of luminous intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

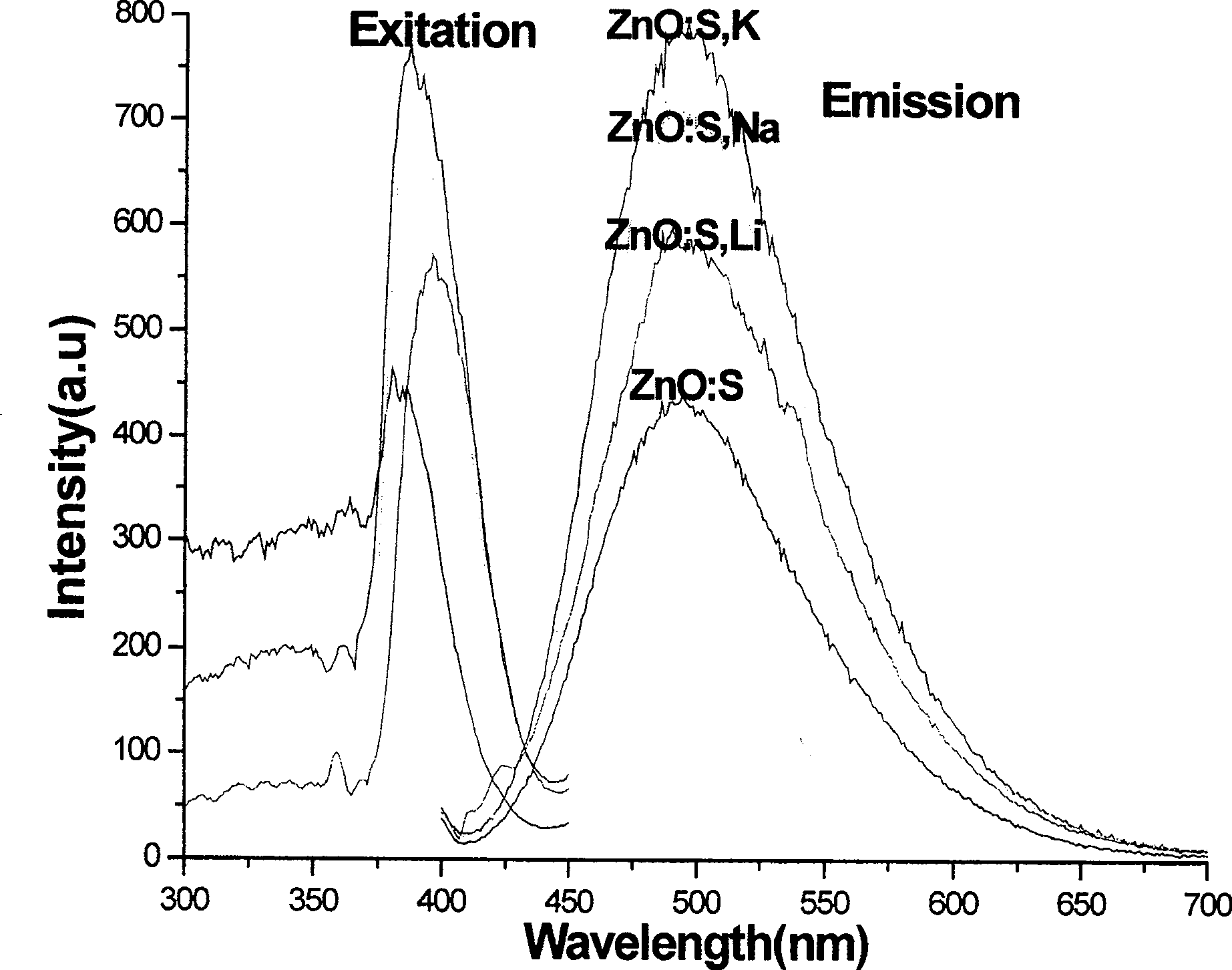

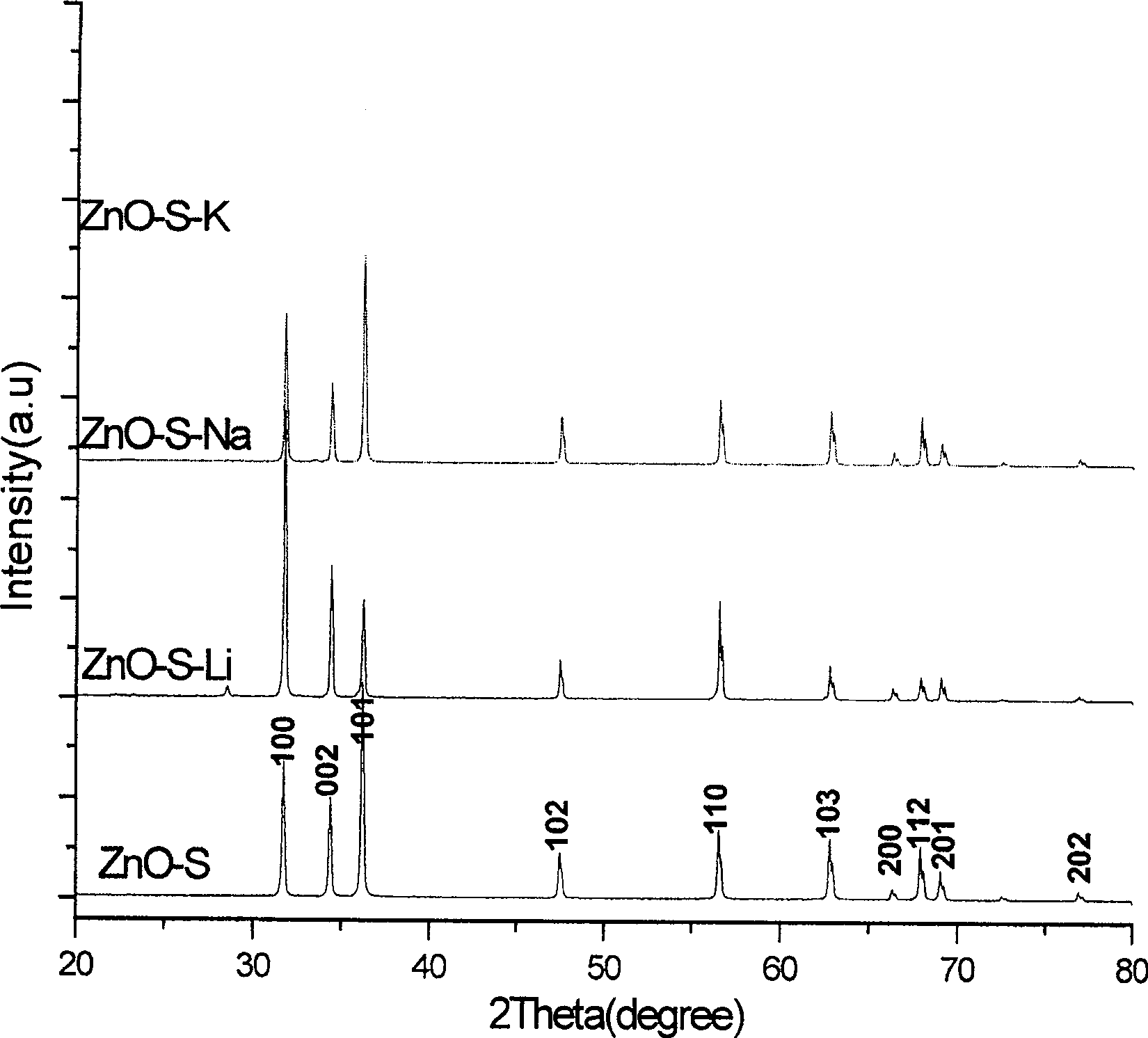

Embodiment 1

[0040] Weigh 9.7g ZnS and 0.6030g NaCl, add them to 50mL ethanol solution, stir in a water bath at 65°C for 10min, then ultrasonically disperse for 5min, keep heating in a water bath at 65°C and continue stirring for 30min, then distill the ethanol under reduced pressure at 70°C To obtain the precursor, put the above precursor in a muffle furnace for sintering at 850°C for 2 hours, and then grind it a little to obtain the target product.

Embodiment 2

[0042]Weigh 9.7g ZnS and 0.6042g LiCl.H20, add to 50mL ethanol solution, stir in 65℃ water bath for 10min, then ultrasonically disperse for 5min, keep stirring in 65℃ water bath for 30min, then distill under reduced pressure at 70℃ The ethanol was removed to obtain the precursor, and the above precursor was sintered in a muffle furnace at 850°C for 2 hours, and then ground slightly to obtain the target product.

Embodiment 3

[0044] Weigh 9.7g ZnS and 0.7455g KCl, add to 50mL ethanol solution, stir in 65°C water bath for 10min, then ultrasonically disperse for 5min, keep heating in 65°C water bath and continue stirring for 30min, then remove ethanol by distillation under reduced pressure at 70°C To obtain the precursor, put the above precursor in a muffle furnace for sintering at 850°C for 2 hours, and then grind it a little to obtain the target product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com