Method for manufacturing large area evenly distributed cuprum octahedron nanometer particle

A uniformly distributed, nano-particle technology, applied in the direction of chemical instruments and methods, crystal growth, process efficiency improvement, etc., to achieve the effect of good industrialization prospects, easy realization, and easy products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

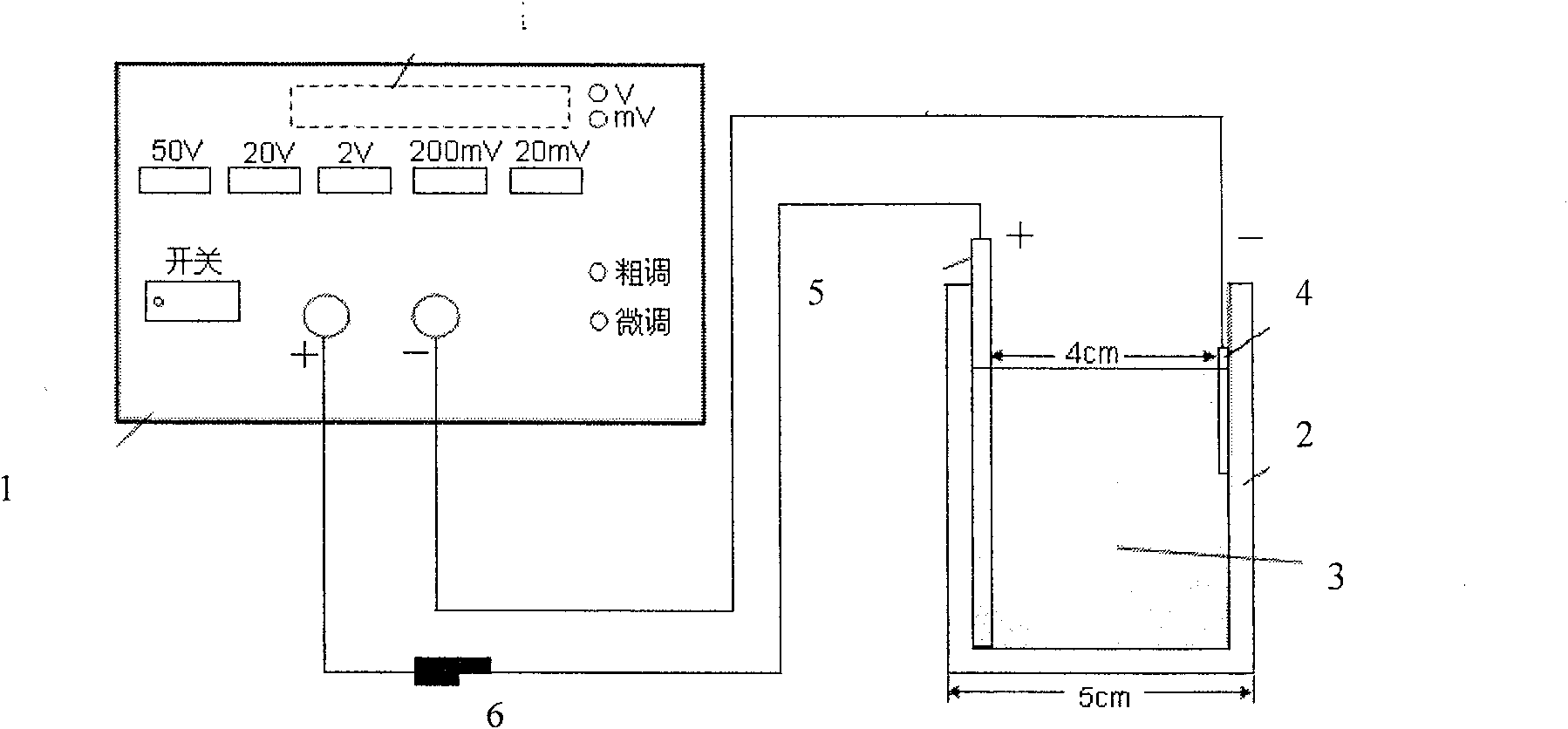

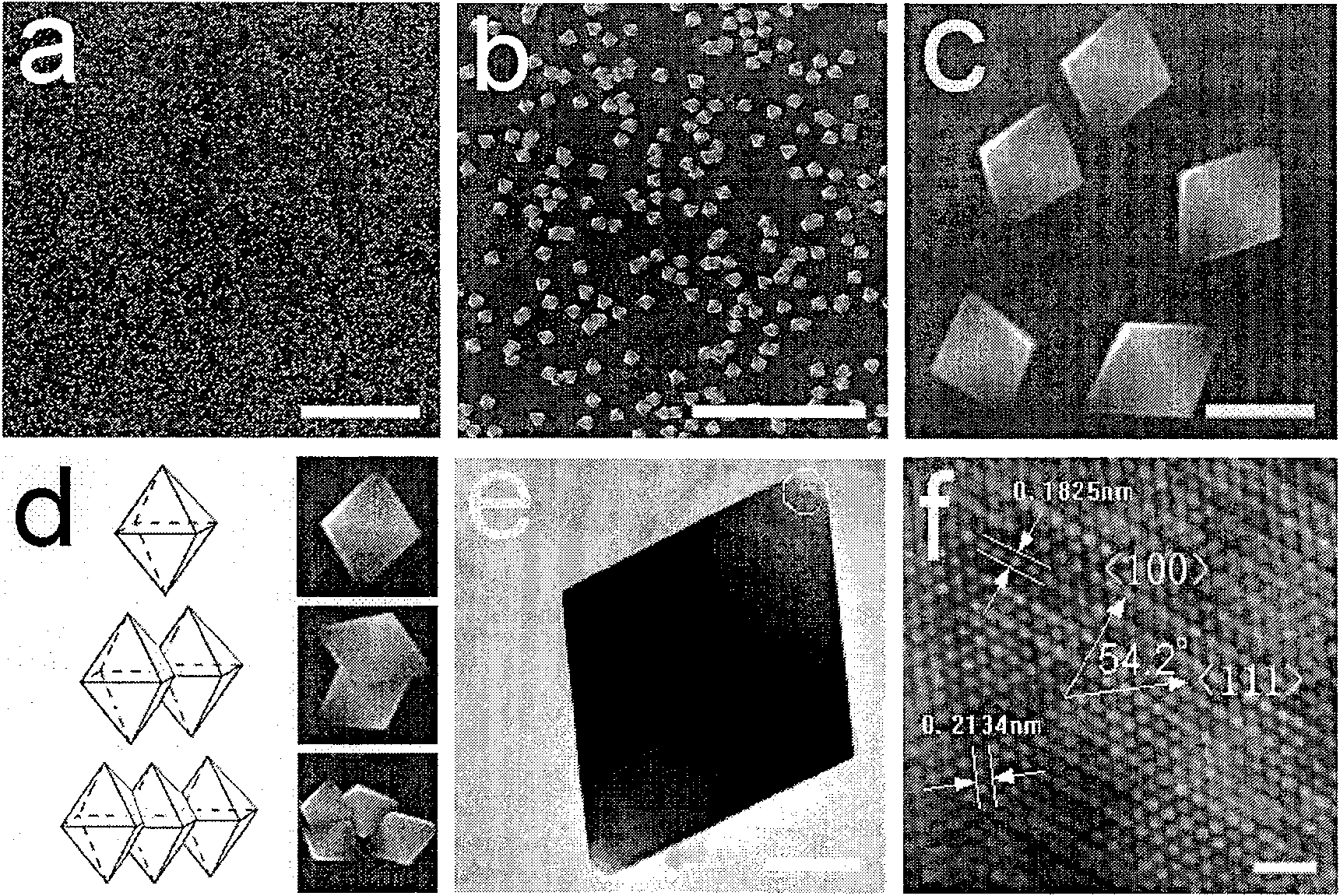

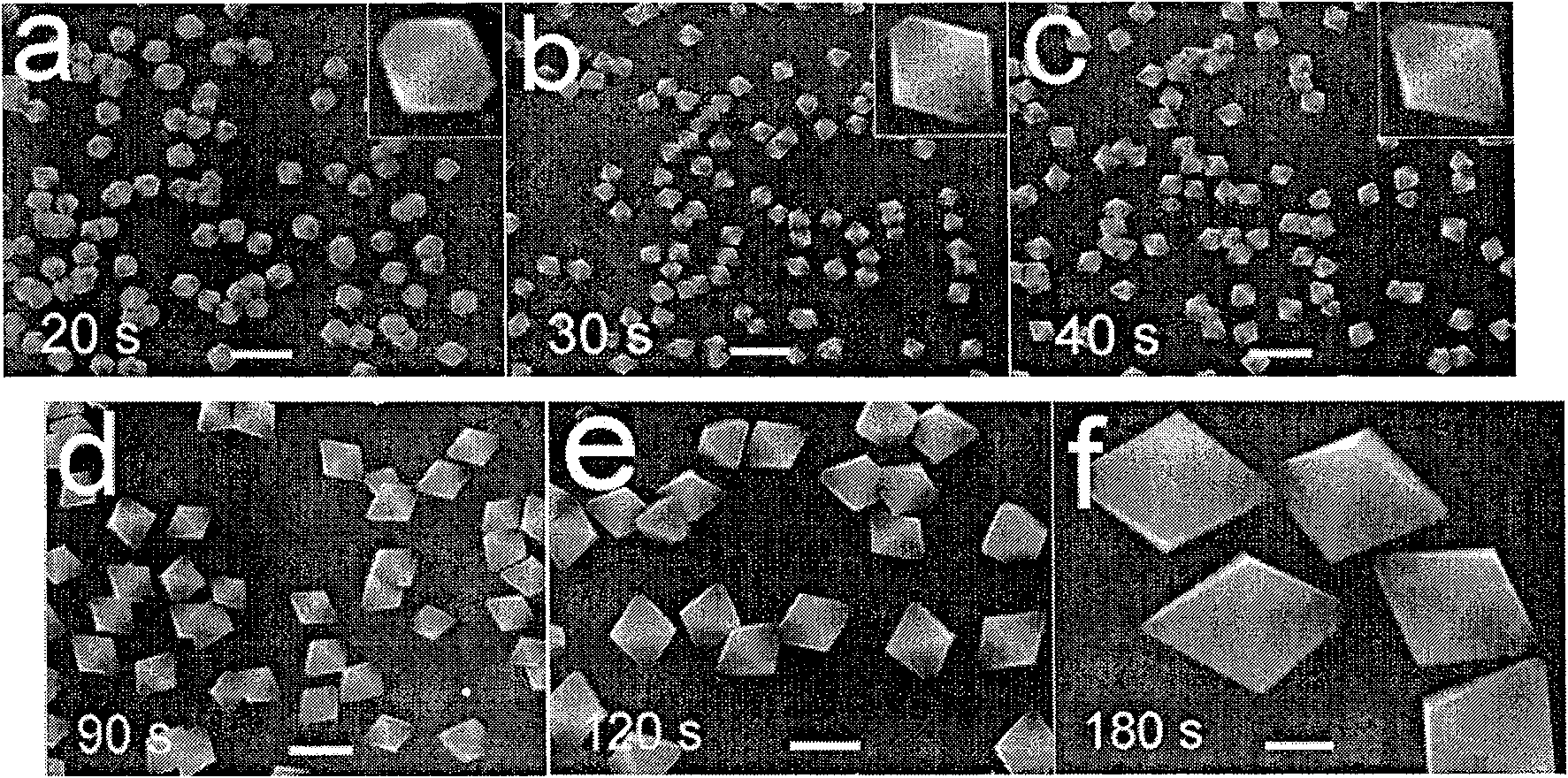

[0026] Applying the direct electrodeposition method to the shape-controlled synthesis of metal nanoparticles not only realizes the anisotropic growth of crystals, but also makes the size and distribution density of metal nanoparticles controllable. At first, configure certain copper salt solution (the present invention has adopted CuSO 4 ·5H 2 O, analytically pure), and take out a certain volume of solution and pour it into the electrolytic cell; then insert the two prepared electrodes into the electrolytic cell, in order to reduce the voltage acting on the working electrode, connect a resistor with a certain resistance value in series to the entire circuit Medium; in the constant voltage mode, through direct current deposition for a certain period of time, the electrodeposited product will be formed on the surface of the negative electrode; the negative electrode is washed repeatedly with deionized water, and finally air-dried. In this way, large-area monodisperse supported ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com