Powder of rare-earth oxides with high apparent density and low specific surface area, and preparation method

A rare earth oxide, low specific surface area technology, applied in rare earth metal compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problem of unspecified specific surface area and particle size, etc., and achieves low cost, simple preparation process, and high yield. high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] LaCePr mixed rare earth chloride solution obtained from Baotou Mine by grouping neodymium and samarium, and then separating praseodymium and neodymium, adjusted to a concentration of 0.6M and a pH value of 1.5. Take 1000mL of this solution, add 0.015g of polyacrylamide, and heat to 45°C , add 1.4L, 1.6M sodium carbonate aqueous solution under constant stirring, filter after standing for 2 hours, wash with water, dry at 80°C, burn at 1000°C for 2 hours, the heating rate is 300°C / h, and the bulk density is obtained 1.99g.cm -3 , The specific surface area is 1.06g.m -2 , LaCePr mixed rare earth oxide powder with a volume center particle diameter of 27.33 μm in a normal distribution.

Embodiment 2

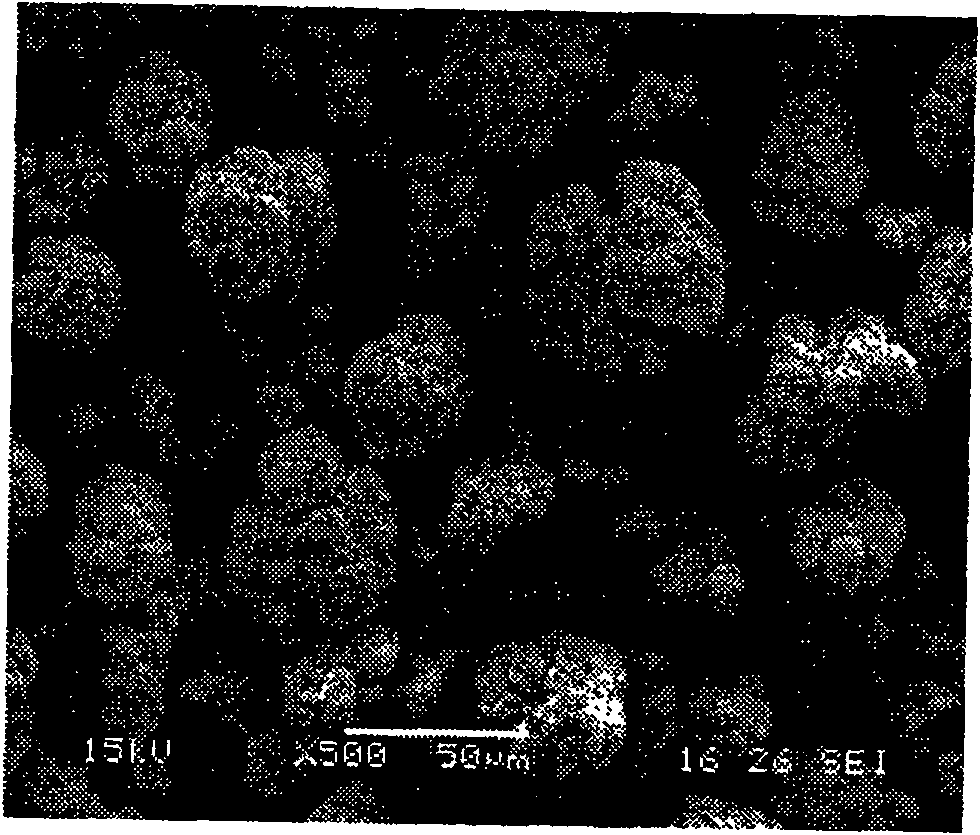

[0027] The cerium nitrate solution obtained by dissolving industrial cerium carbonate in nitric acid is adjusted to a concentration of 0.9M and a pH value of 2.5. Take 1000mL of this solution, add 0.028g of tributyl phosphate, heat to 50°C, and add 3L under constant stirring. 1M ammonium bicarbonate aqueous solution, after standing for 4 hours, filter, wash with water, dry at 100°C, burn at 1000°C for 2 hours, the heating rate is 200°C / h, and the bulk density is 2.12g.cm -3 , The specific surface area is 0.85g.m -2 , Cerium oxide powder with a normal distribution and an average particle size of 29.07 μm. SEM of cerium oxide as figure 1 . It can be seen from the scanning electron microscope that CeO 2 It is an aggregate, cauliflower-like.

Embodiment 3

[0029]Dissolve yttrium oxide in hydrochloric acid to obtain yttrium chloride solution, adjust to a concentration of 0.58M, and a pH value of 2.3. Take 900ml of this solution, add 0.018g of polyacrylamide, heat to 45°C, and add 1L, 2.1M Ammonium bicarbonate aqueous solution, after standing for 12 hours, filtered, washed with water, dried at 120°C, burned at 900°C for 2 hours, and the heating rate was 100°C / h to obtain a bulk density of 2.07g.cm -3 , The specific surface area is 2.18g.m -2 , Yttrium oxide powder with a normal distribution and an average particle size of 24.51 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com