A polymer solar battery and its making method

A technology of solar cells and polymers, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as unfavorable large-scale industrial production, difficulty in accurate control, high process requirements, etc., to increase photoelectric conversion efficiency and improve fill factor , The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

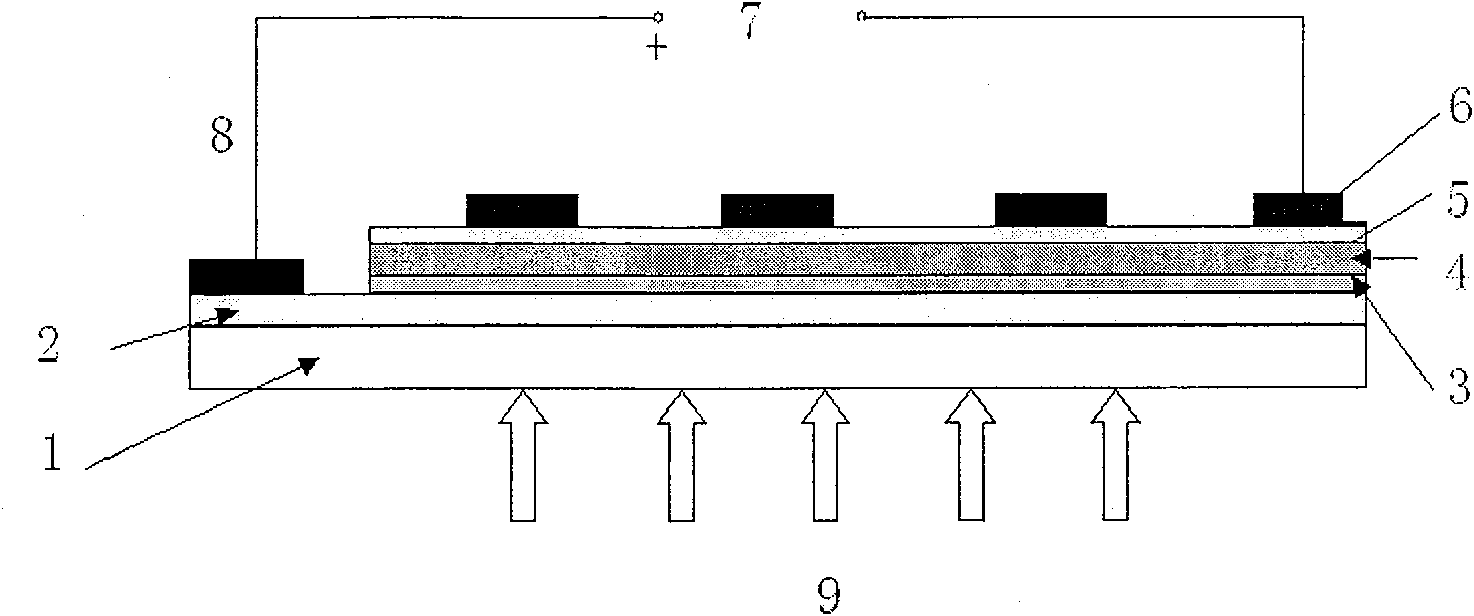

[0023] Embodiment 1 (comparative example), the preparation of the solar cell without cathode modification layer

[0024] The transparent conductive glass sputtered with ITO (anode) was cleaned sequentially with cleaning, deionized water, acetone, and isopropanol, and then the surface of the substrate was treated with ozone, and then spin-coated with 30 nm thick PEDOT:PSS as the anode Modify the film and dry it at 150°C for 10 minutes. A mixed solution of 3 mg per ml of MEH-PPV and PCBM 1:4 (mass ratio) was directly spin-coated on the above-mentioned anode-modified substrate at a speed of 1600 revolutions per minute (rpm) as a photoelectric active layer, and then Dry at 50°C for 30 minutes, and cool to room temperature naturally; finally, at 5×10 -5 150nm aluminum was vacuum-evaporated under Pa to serve as the cathode.

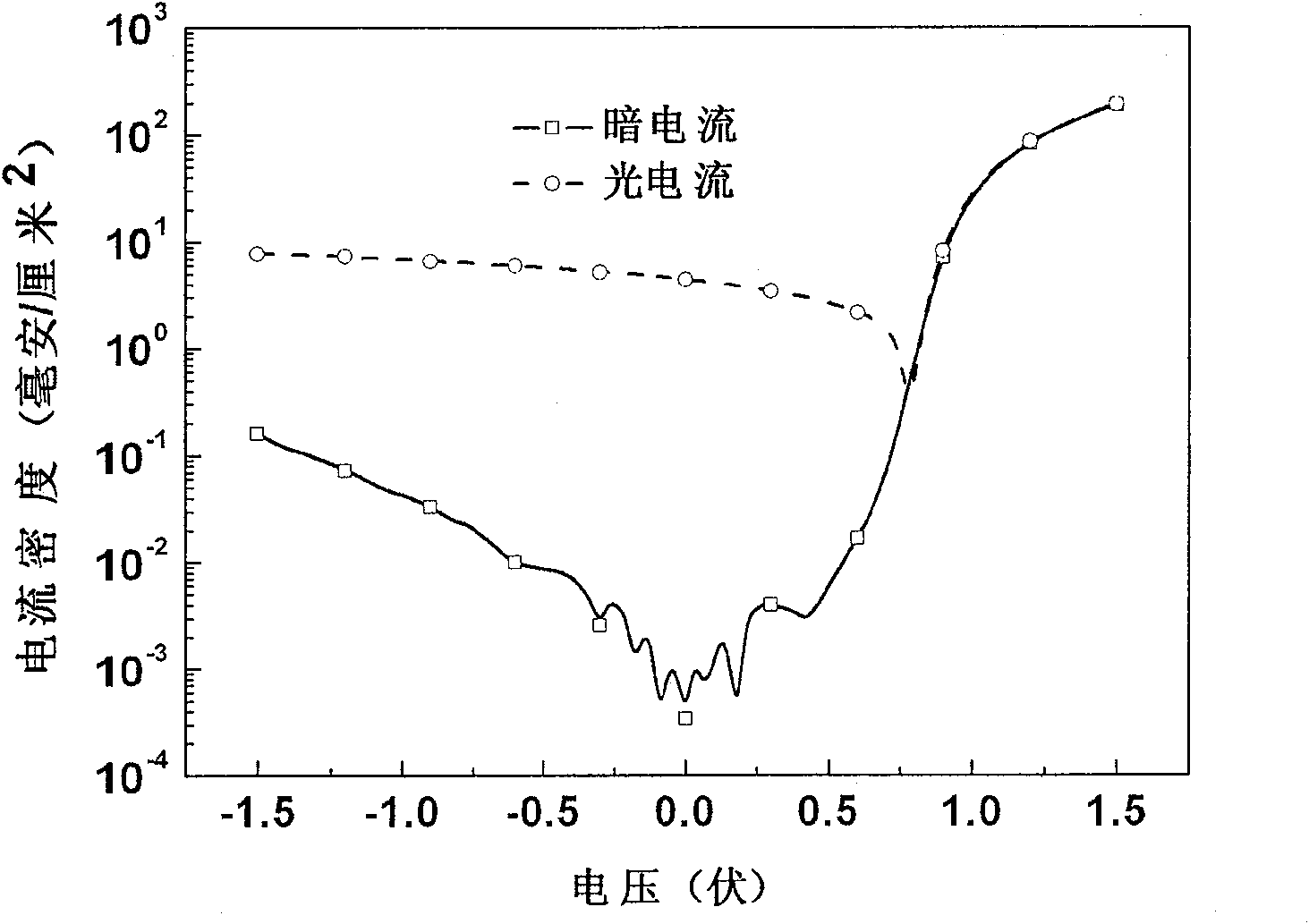

[0025] figure 2 The current-voltage curves of the device without light irradiation and with simulated sunlight irradiation of 100 mW / cm2 are given. The pr...

Embodiment 2

[0026] Embodiment 2, the preparation of solar cell of the present invention

[0027] Accurately measure 50 microliters of 70% diisopropoxybis(acetylacetonate)titanium in isopropanol solution (purchased from Alfa Aesar, USA), and add it to 1000 microliters of anhydrous and oxygen-free isopropyl alcohol solution. Alcohol, stir well, let it stand, and filter with a 5 micron filter head, set aside.

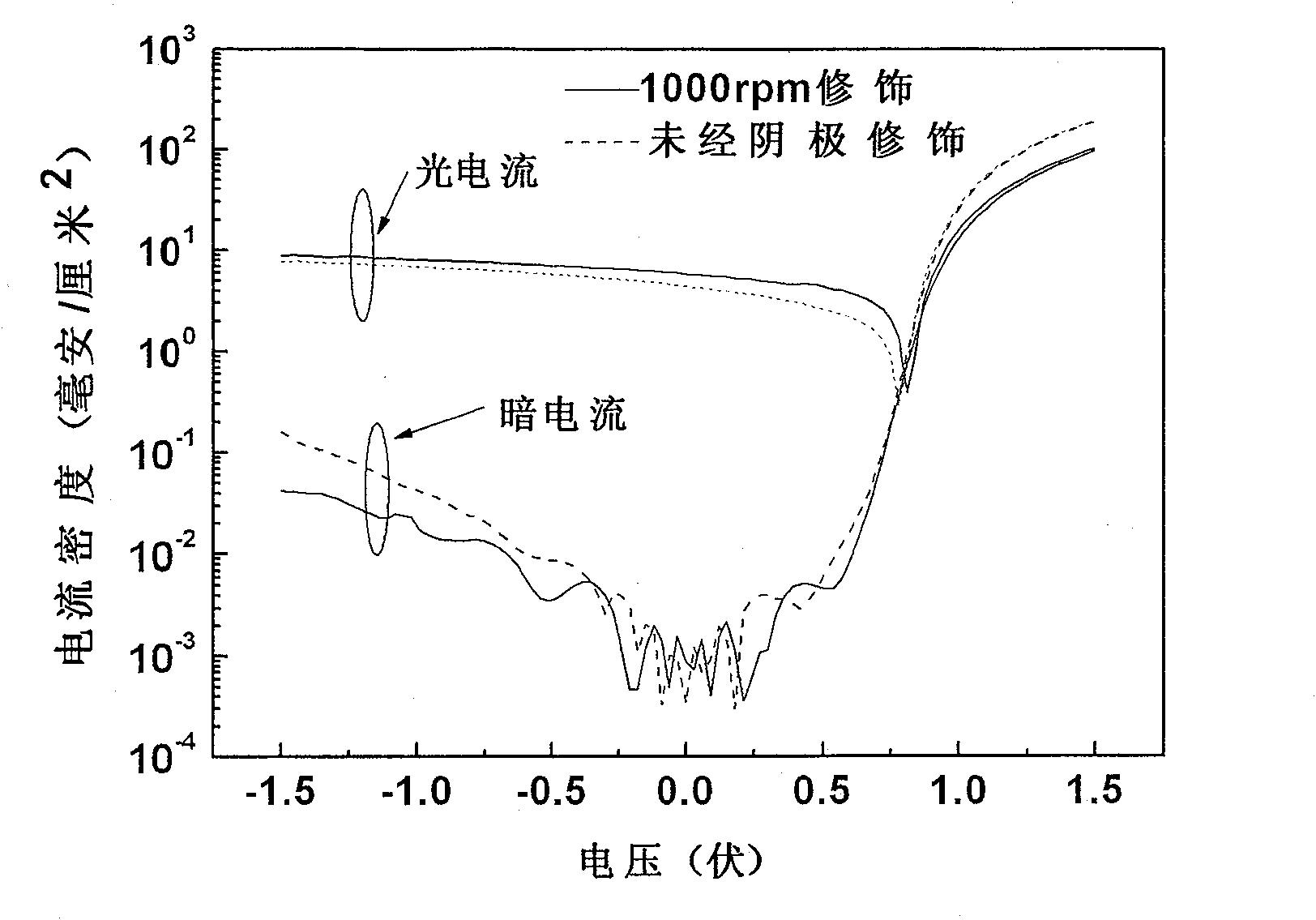

[0028] The transparent conductive glass sputtered with ITO (anode) was ultrasonically cleaned with detergent, deionized water, acetone, and isopropanol in sequence, and then the surface of the substrate was treated with ozone, and then spin-coated with 30 nm thick PEDOT:PSS as Anodically modified film, dried at 150°C for 10 minutes. A mixed solution of 3 mg per ml of MEH-PPV and PCBM 1:4 (mass ratio) was directly spin-coated on the above-mentioned anode-modified substrate at a speed of 1600 revolutions per minute (rpm) as a photoelectric active layer, and then Dry at 50°C for 30 min...

Embodiment 3

[0031] The transparent conductive glass sputtered with ITO (anode) was ultrasonically cleaned with detergent, deionized water, acetone, and isopropanol in sequence, and then the surface of the substrate was treated with ozone, and then spin-coated with 30 nm thick PEDOT:PSS as Anodically modified film, dried at 150°C for 10 minutes. A mixed solution of 3 mg per ml of MEH-PPV and PCBM 1:4 (mass ratio) was directly spin-coated on the above-mentioned anode-modified substrate at a speed of 1600 revolutions per minute (rpm) as a photoelectric active layer, and then Dry at 50°C for 30 minutes, and cool to room temperature naturally. The isopropanol solution of the obtained diisopropoxybis(acetylacetonate)titanium is directly spin-coated on the top of the photoelectric active layer at a speed of 4000rpm, and dried in vacuum at 80° C. for 30 minutes, and cooled naturally; finally , at 5 x 10 -5 150nm aluminum was vacuum-evaporated under Pa to serve as the cathode.

[0032] Diisopro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com