Rhizopus oryzae non-carrier immobilization cell culturing method

A carrier-free immobilization and cell culture technology, applied in the field of microbiology and cell engineering, can solve the problems of unfavorable cell coordination, affecting lifespan, and low overall activity, and achieve the effects of smooth synthesis, easy repeated use, and high fermentation intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] Rhizopus oryzae carrier-free immobilized cell culture steps are as follows:

[0027] (1) Preparation of Rhizopus oryzae spores

[0028] The rhizopus oryzae strain Rhizopus oryzae (Rhizopus oryzae / AS 3.819) was streak-inoculated on the potato dextrose (PDA) plate, and the culture temperature was set at 32 ° C on the first day, and the relative culture humidity was 70%, which was conducive to mycelial growth. It is 34 ℃ to set the culture temperature every day, and the relative culture humidity is 30%, which is beneficial to the generation of spores. After the black dense spores completely cover the white hyphae, they can be ready to collect, and mature Rhizopus oryzae spores are obtained.

[0029] (2) Preparation of Rhizopus oryzae spore emulsion suspension

[0030] All the Rhizopus oryzae spores in the 250mL Erlenmeyer flask are all scraped and washed into sterile water, and then inoculated in a 5L fermentation tank with a straight plate stirring paddle. The medium in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

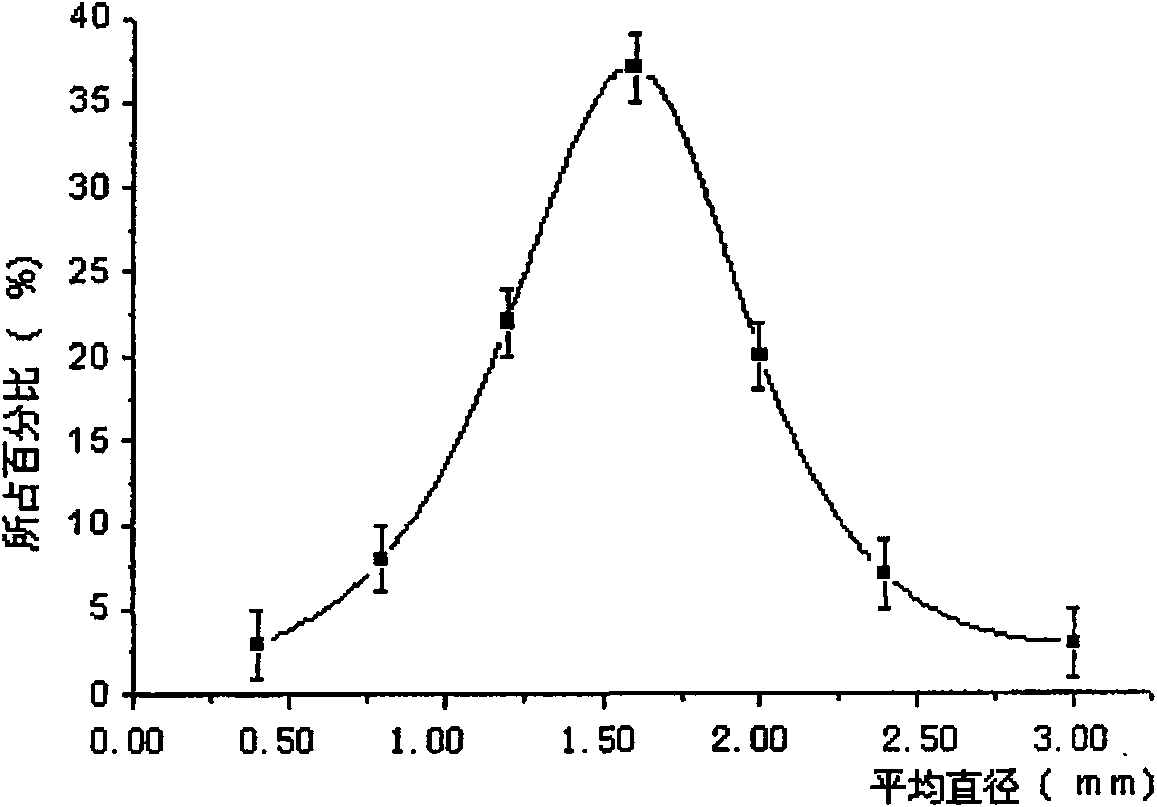

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com