Magnesium oxide base calalytic-absorber for denitrogen of smoke and its preparation method

A magnesia-based, adsorbent technology, applied in the field of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

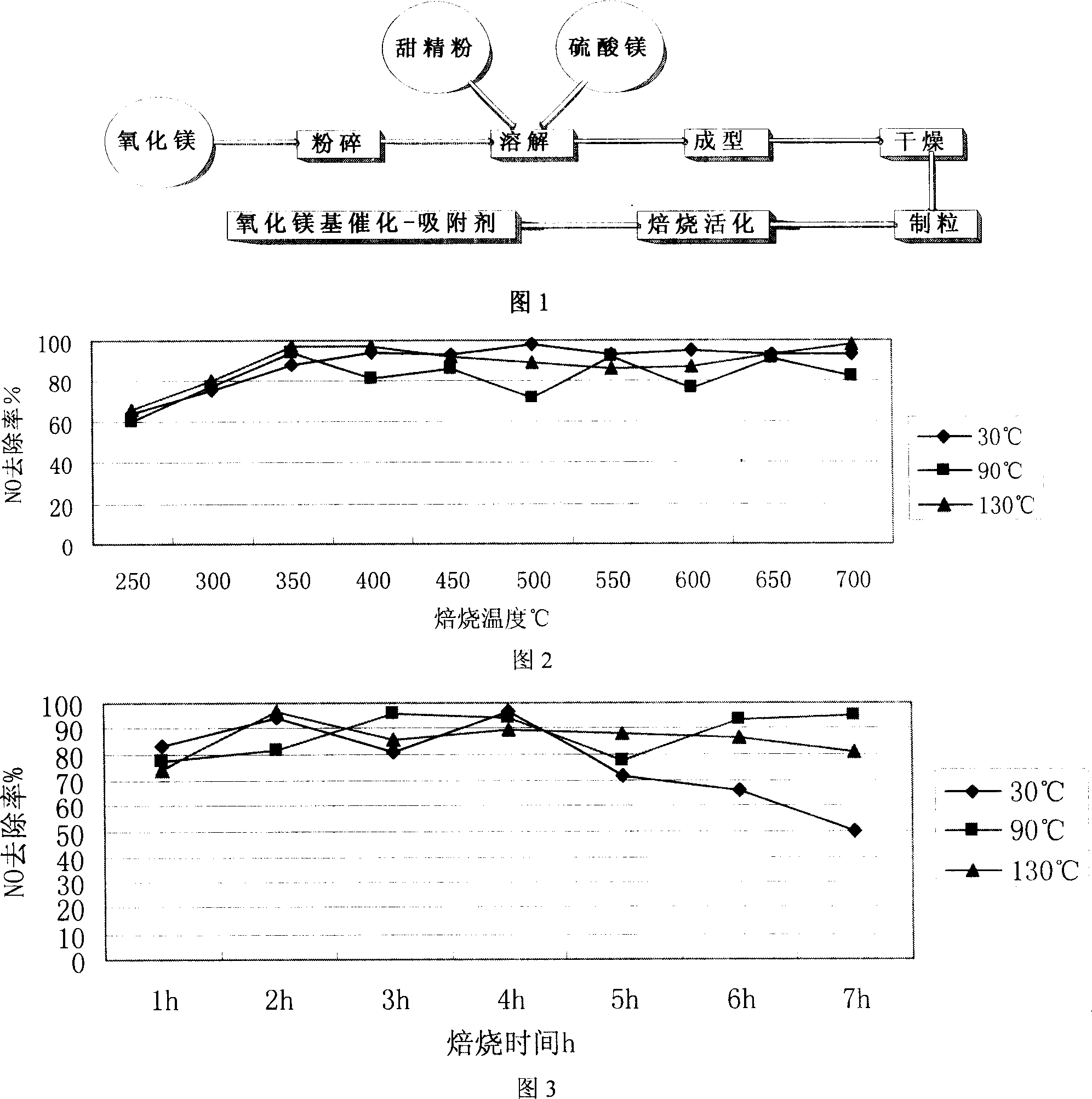

Method used

Image

Examples

Embodiment 1

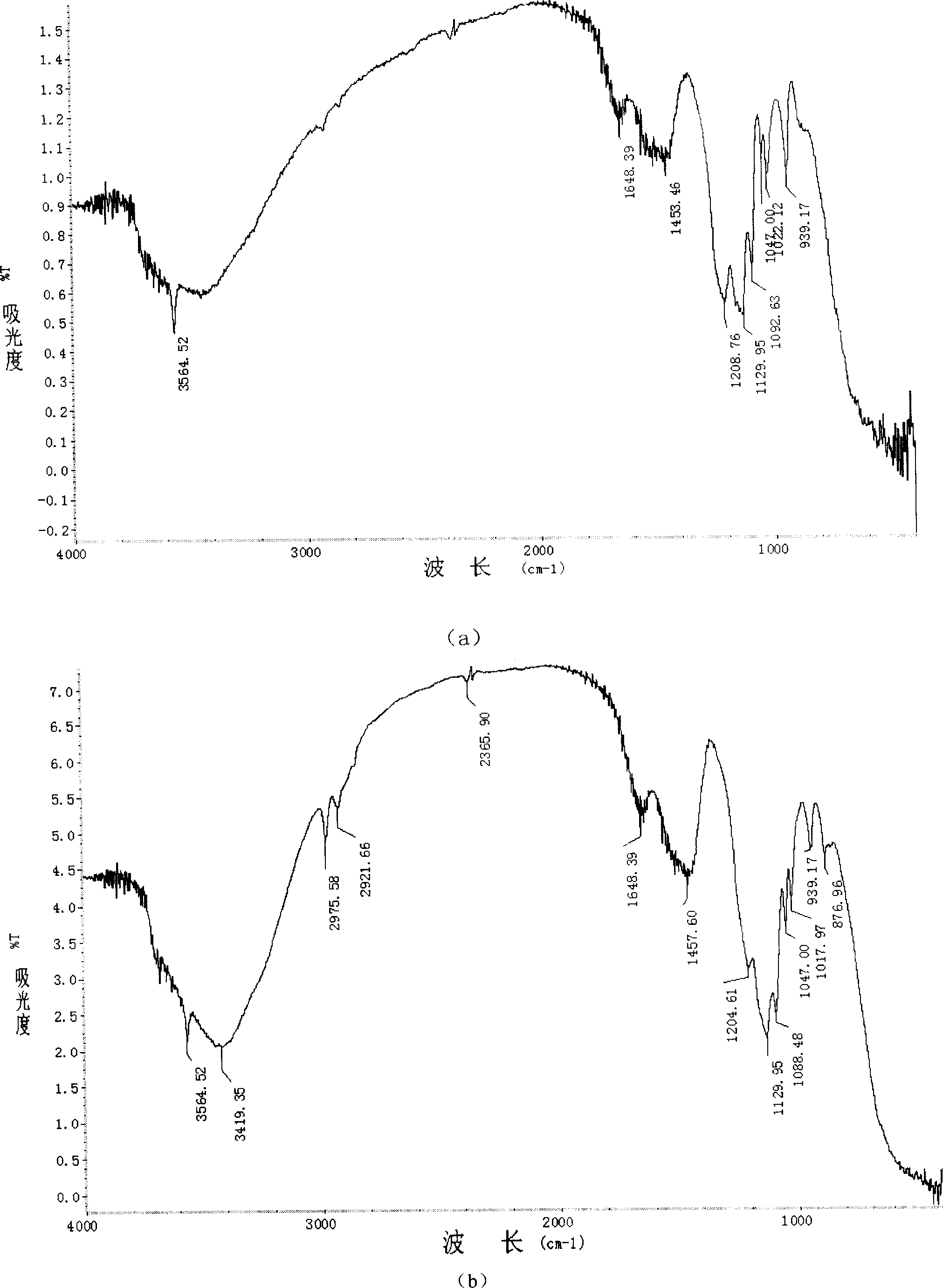

[0114] Orthogonal experiments were designed as follows.

[0115] Table 1 Factors and horizontal orthogonal design table

[0116] factor

MgO(%)

Sweetener powder (%)

MgSO 4 (%)

Level

Level

Level

67(1)

80(2)

90(3)

0.5(1)

0.75(2)

1(3)

33(1)

20(2)

10(3)

[0117] According to the table above, the oxidation-based catalyst-adsorbent orthogonal design and experimental results are shown in Table 2.

[0118] Table 2 Raw material ratio orthogonal design scheme and experimental results

[0119] column

1

2

3

factor

MgO

sweet powder

MgSO 4

Experimental results

NO removal rate

Experiment 1

Experiment 2

Experiment 3

Experiment 4

Experiment 5

Experiment 6

1

1

1

2

2

2

1

2

3

1

2...

Embodiment 2

[0125] Catalyst is prepared according to the following process steps:

[0126] (1) Crushing

[0127] Grind the light-burned magnesium product and sieve it to -200 mesh; because magnesium oxide is placed in the air, it is easy to absorb moisture in the air, and in addition, the generated magnesium hydroxide may also react with carbon dioxide in the air to form magnesium carbonate and agglomerate, so The agglomerated industrial magnesia should be ground into powder and baked in a muffle furnace at 650°C for 3 hours to remove moisture and some carbonates.

[0128] (2) dissolve

[0129] Add the pulverized light-burned magnesia to MgSO that has been dissolved in water at 40°C 4 and sweet powder additive mixture, mix evenly, and stir with water to adjust to a moldable soft state. The material ratio is calculated according to the weight percentage: 60% of light-burned magnesium oxide, MgSO 4 30%, sweet powder 2%, water 8%.

[0130] (3) Molding

[0131] Use extruding machine to ...

Embodiment 3

[0145] Catalyst is prepared according to the following process steps:

[0146] (1) Crushing

[0147] Grind the light-burned magnesium product and sieve it to -200 mesh; because magnesium oxide is placed in the air, it is easy to absorb moisture in the air, and in addition, the generated magnesium hydroxide may also react with carbon dioxide in the air to form magnesium carbonate and agglomerate, so The agglomerated industrial magnesia should be ground into powder and baked in a muffle furnace at 650°C for 3 hours to remove moisture and some carbonates.

[0148] (2) dissolve

[0149] Add the pulverized light-burned magnesia to MgSO that has been dissolved uniformly at 50°C with water as the solvent 4 and sweet powder additive mixture, mix evenly, and stir with water to adjust to a moldable soft state. The material ratio is calculated according to weight percentage: 80% of light-burned magnesium oxide, MgSO 4 10%, sweet powder 3%, water 7%.

[0150] (3) Molding

[0151] Ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com