ZrO2-SiO2 compound oxides, its preparation method and application

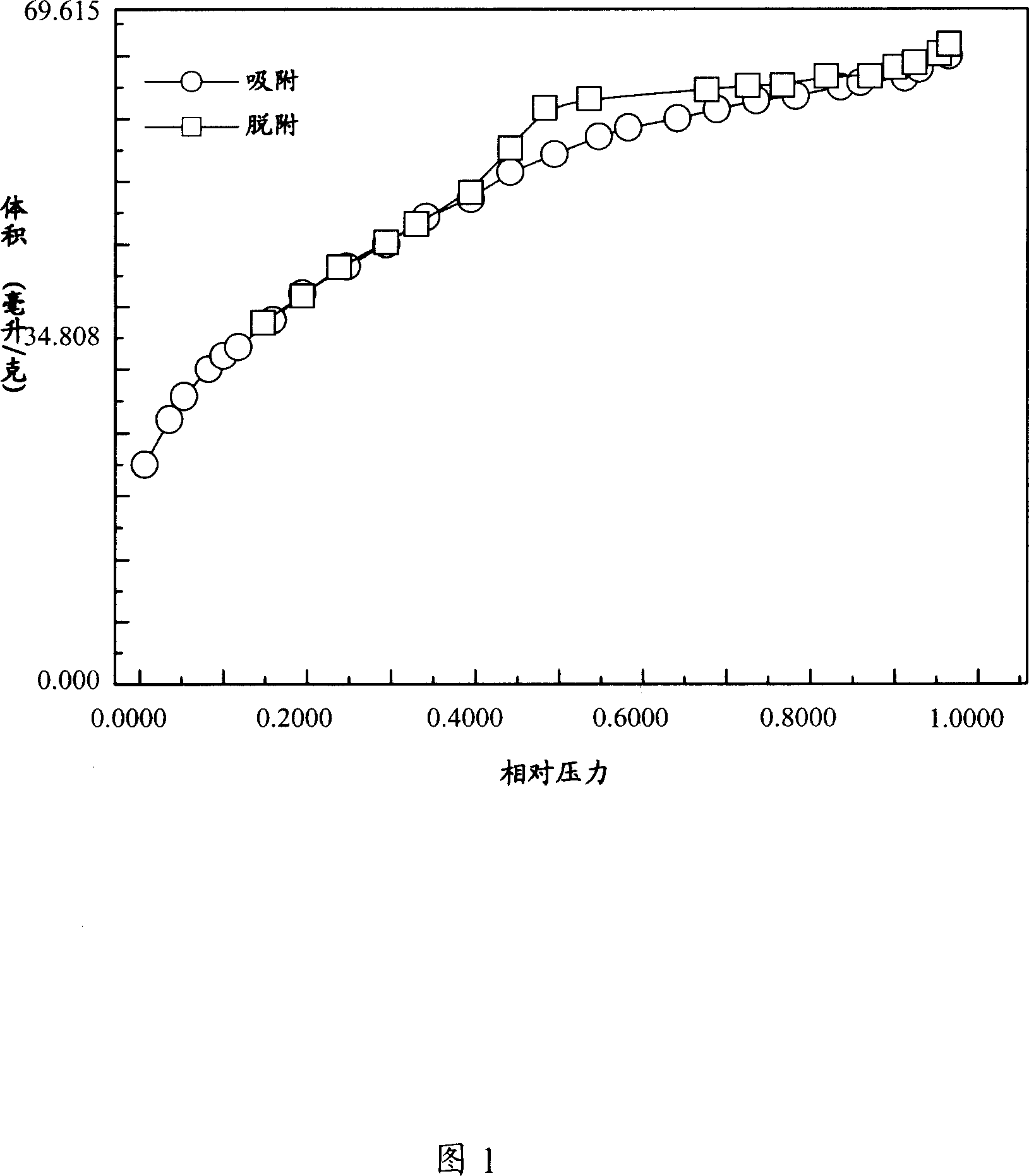

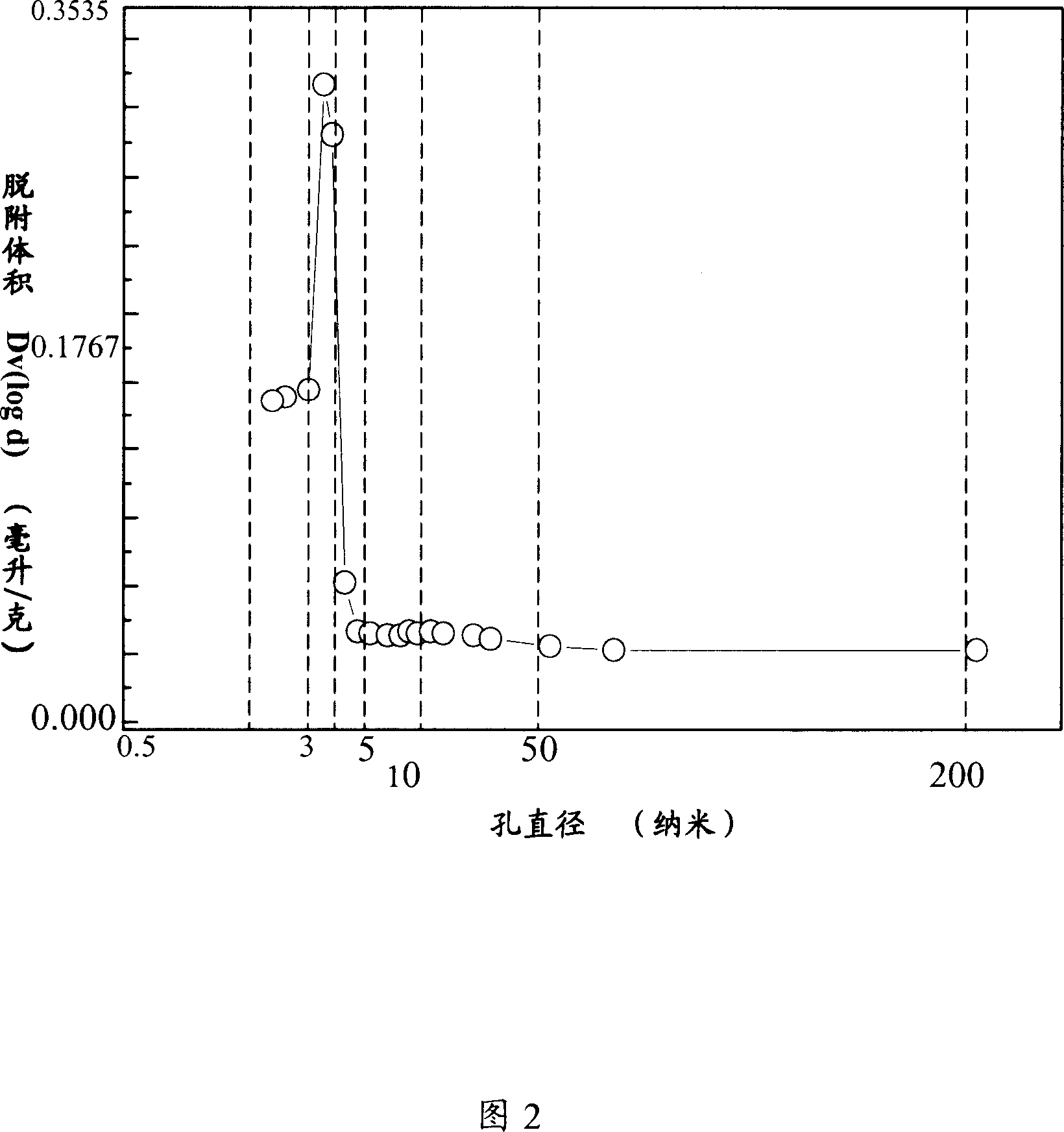

A technology of composite oxides and oxides, applied in chemical instruments and methods, catalyst activation/preparation, hydrocarbons, etc., can solve problems such as poor hydrothermal stability, achieve concentrated pore size distribution, good structural thermal stability, and specific The effect of large surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

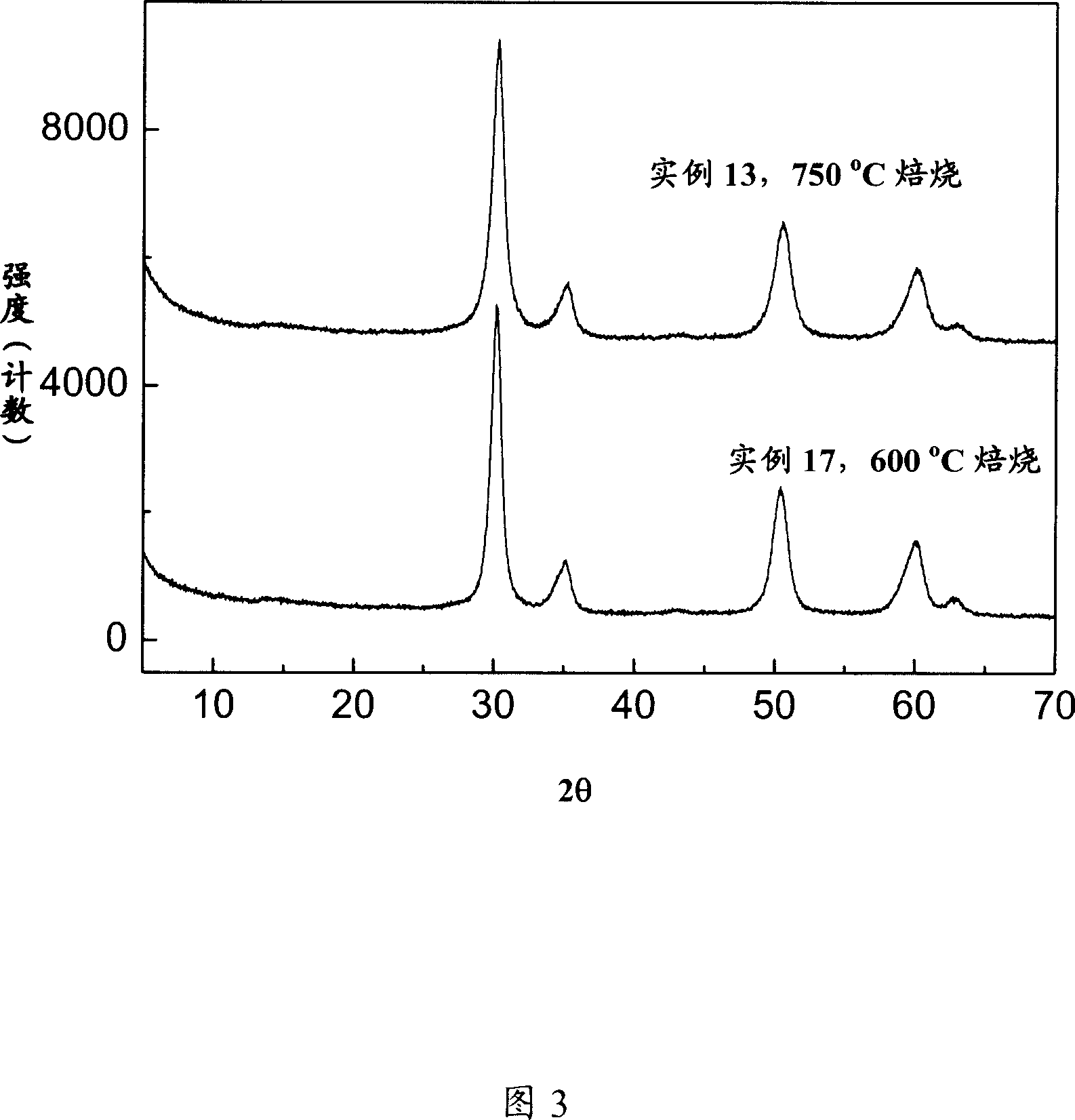

Examples

preparation example Construction

[0019] The preparation method of the composite oxide provided by the present invention comprises adding the silicon-containing compound and the surfactant into the zirconium-containing compound solution under stirring to form a mixture, adding the basic compound solution, and adjusting the pH value of the system from 10 to 12 to Form a sol, age the sol under stirring and standing respectively, obtain a hydrogel after washing and filtering, then dry and roast, and the surfactant has the general formula R(CH 3 ) 3 The quaternary ammonium salt of NX, R is an alkyl group containing 12-22 carbons, X is a halogen, preferably chlorine or bromine, and the ratio of surfactant to Zr in the zirconium compound is 2-8% by mass.

[0020] The zirconium-containing compound described in the above preparation method is preferably ZrOCl 2 , ZrCl 4 , Zr(NO 3 ) 2 or Zr(NO 3 ) 4 , the silicon-containing compound is preferably sodium silicate, silicon dioxide or ethyl orthosilicate, and the su...

example 1

[0030] Prepare ZrO of the present invention 2 -SiO 2 composite oxides.

[0031] (1) 1.74 grams of ethyl orthosilicate (produced by Shanghai Pharmaceutical Co., Ltd., analytically pure) and 0.28 grams of cetyltrimethylammonium bromide C 16 h 33 (CH 3 ) 3 NBr (produced by Tianjin Chemical Reagent Factory, analytically pure) was dripped into 22.09 grams of ZrOCl respectively under the condition of continuous stirring 2 ·6H 2 O (produced by Shanghai Pharmaceutical Co., Ltd., analytically pure) and 300 milliliters of deionized water were prepared, and the stirring was continued until a transparent mixed liquid was formed.

[0032] (2) Aqueous ammonia solution with a concentration of 2% by mass is added dropwise at a rate of 10 to 15 ml / min to the liquid mixture prepared in step (1) under continuous stirring until finally milky white hydrosol is formed, and the mixture system is controlled The pH value is 11.

[0033] (3) Continue to stir and age the hydrosol at 25°C for 4 h...

example 2~6

[0040] Example 2~6 adopts different zirconium compounds, prepares ZrO according to the method for example 1 2 -SiO 2 . The zirconium compound used in each example and the addition of each raw material and the ZrO produced 2 -SiO 2 The physical and chemical properties of the composite oxides are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com