Method for treating waste gas by using metal thin film adsorption and desorption

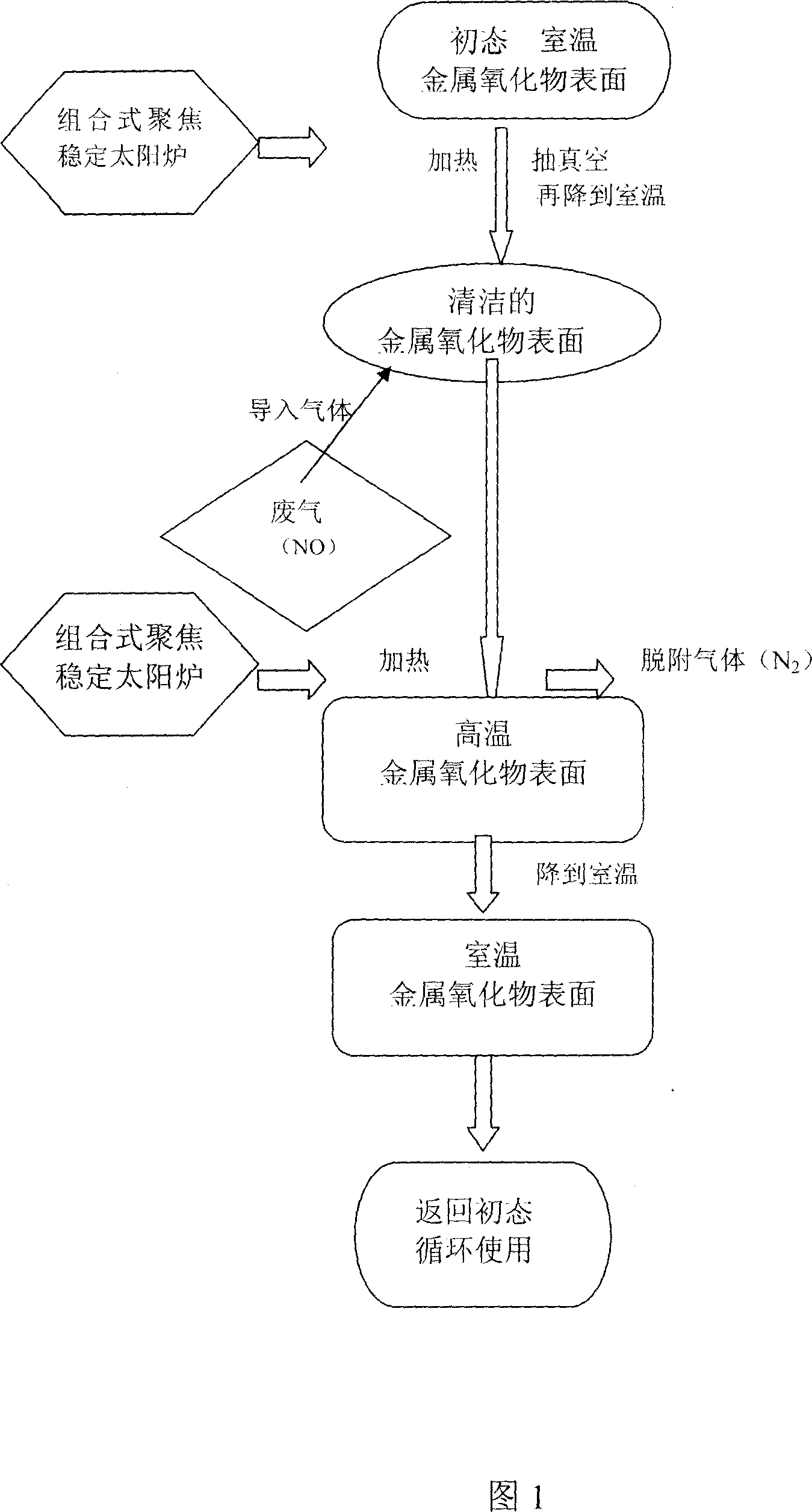

A metal thin film, adsorption treatment technology, applied in separation methods, chemical instruments and methods, metal material coating processes, etc., can solve problems such as gas pollution, and achieve the effects of energy saving, wide application value, and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0016] Example: Using ZDL-2051 vacuum coating machine to evaporate TiO 2 Thin film, ZDL-2051 vacuum coating machine, is composed of vacuum system, control system, combined evaporation source, ion bombardment source, workpiece turret and evaporation table, and added quadrupole mass spectrometry temperature programmed thermal desorption TPD detection gas equipment, The quadrupole mass spectrometer temperature programmed thermal desorption TPD device is composed of an exhaust system, a measurement system and a temperature control system. The vacuum chamber specification of the vacuum coating machine is Φ2050×2900mm, and the ultimate vacuum degree and working vacuum degree are 1×10 -3 Pa and 2×10 -2 Pa, restore the original vacuum degree for the second time in less than 7 minutes, the static leak rate is 1.0Pa / s, the total power of the equipment is 200KVA, the air source inlet pressure is greater than 0.6Mpa, and the total water consumption is 9M 3 / h.

[0017] The film of envi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com