Sheet natrium/lithium-manganese material having high specific surface area and preparation method thereof

A high specific surface area, flaky sodium technology, applied in the field of mesoporous oxide materials, can solve the problems that it is difficult to obtain mesoporous manganese oxide, manganese oxide mesoporous materials, poor repeatability, etc., and achieve excellent electrochemical performance , mild conditions and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

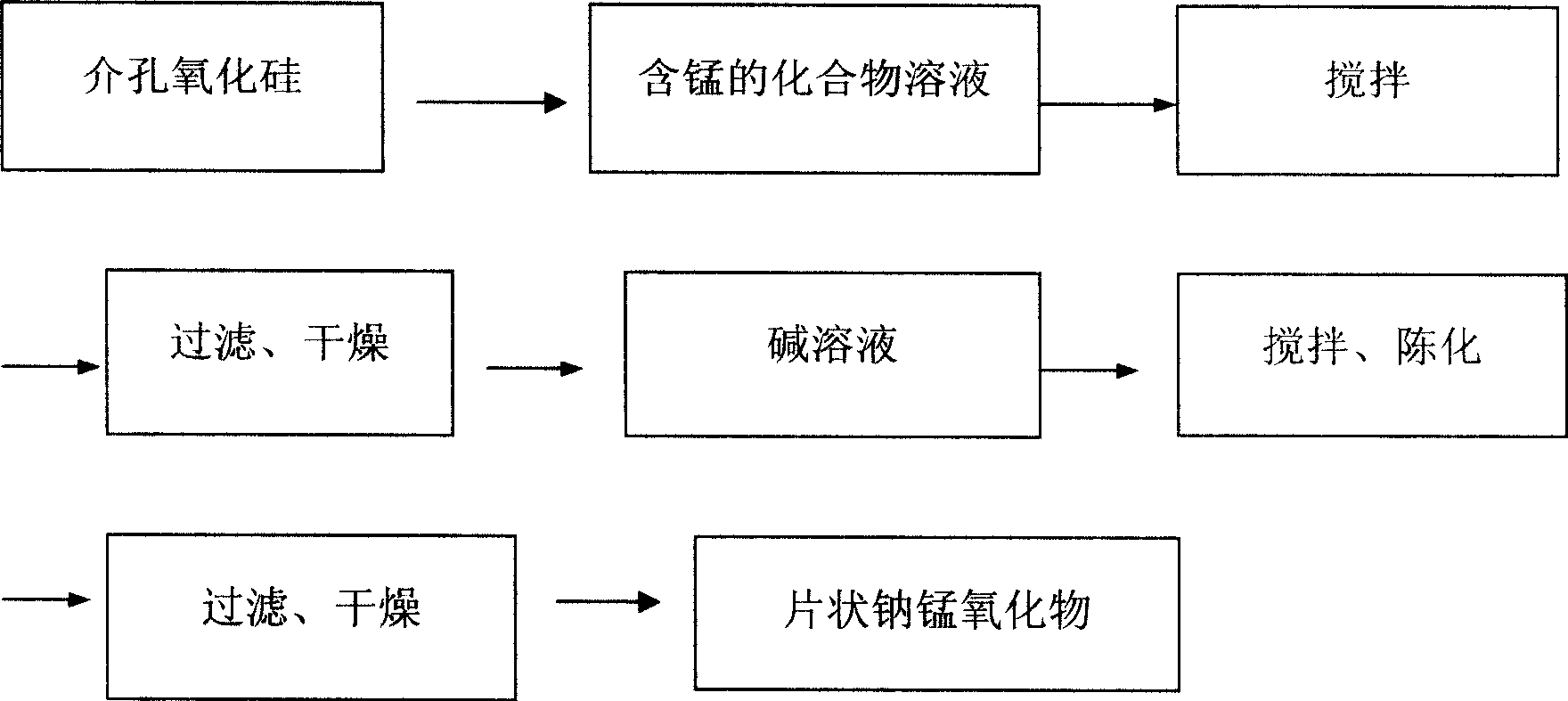

Method used

Image

Examples

Embodiment 1

[0026] Manganese source is manganese nitrate Mn(NO 3 ) 2 ; The mesoporous hard template is silicon oxide SBA-15; after the manganese source is injected into the SBA-15 template, the template silicon is removed with sodium hydroxide. According to the formula ratio (weight ratio): 2SiO 2 -SBA15: 38.38Mn(NO 3 ) 2 :4NaOH:50H 2 O; After mixing the materials, stir them magnetically for 4 hours, assemble the manganese ions into the pores of silica SBA-15, dry them at room temperature for 10 hours, and then dry them in air at 100°C for 3 hours. The sample changes from pinkish white to brown, and manganese nitrate gradually Decompose into manganese oxide; then disperse the above powder in sodium hydroxide solution, stir magnetically for 3 hours, age for 7 hours, remove the silicon oxide template, dope excess sodium ions into manganese oxide, and finally wash several times with deionized water , filtered and finally dried in air at 100°C for 12 hours. Low and high magnifications o...

Embodiment 2

[0028] The formula ratio remains unchanged. After the raw materials are mixed and dried at room temperature according to Example 1, the manganese-silicon compound is dried in the air at 100°C for 12 hours, and then implemented according to Embodiment 1. The transmission electron microscope pictures of the obtained material are as follows: image 3 As shown in b, the XRD diffraction pattern is as Figure 5 shown in d.

Embodiment 3

[0030] The formula ratio and other conditions remain unchanged, after drying in the air at 250°C for 12 hours, the final sample is obtained, and the XRD diffraction pattern is as follows: Figure 5 as shown in b.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com