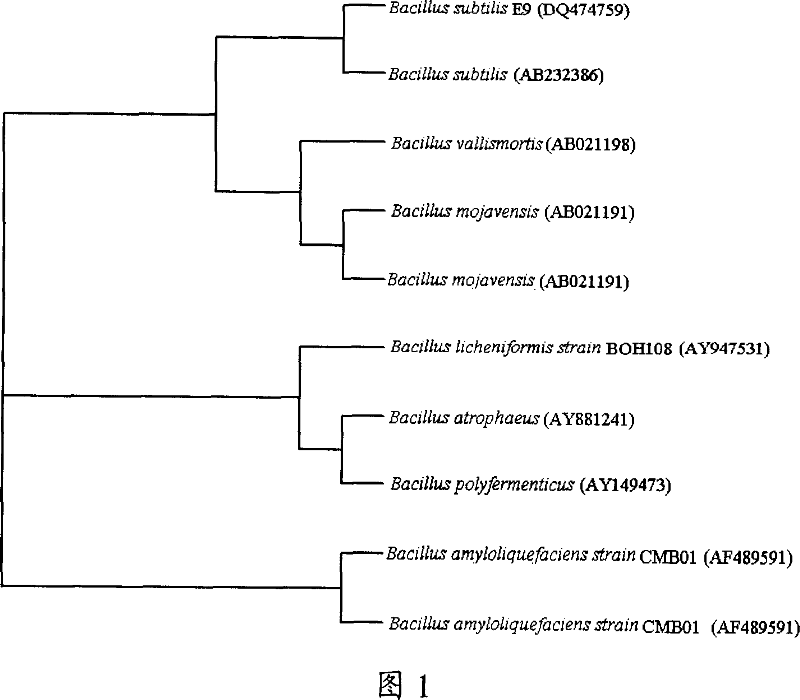

Bacillus subtilis ZJB-063 and its application

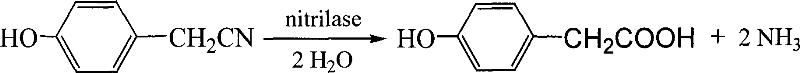

A technology of Bacillus subtilis and ZJB-063, applied in the application field of preparing p-hydroxyphenylacetic acid, can solve the problems of lack of vitality, increasing the difficulty of separation, affecting the yield and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Seed medium formula (weight / volume percentage, the same below): glucose: 1.0%, yeast extract: 0.3%, NaCl: 0.1%, K 2 HPO 4 : 0.02%, KH 2 PO 4 ·3H 2 O: 0.02%, MgSO 4 : 0.02%, prepared with deionized water, pH natural.

[0046] Fermentation medium formula: glucose: 1.8%, yeast extract: 0.5%, K 2 HPO 4 : 0.05%, KH 2 PO 4 ·3H 2 O: 0.05%, MgSO 4 : 0.1%, monosodium glutamate: 0.076%, urea: 0.75%, prepared with deionized water, pH natural.

[0047] Take 100mL of the above-mentioned seed culture medium, evenly distribute it in two 250mL Erlenmeyer flasks, and sterilize. Insert the slant strain Bacillus subtilis ZJB-063, cultivate the bacteria, shake the rotating speed of 150r / min, and cultivate at 28°C for 48 hours as the seed liquid, and set aside.

[0048] Take 1L of the above-mentioned fermentation medium, divide it into ten 500mL shake flasks, and sterilize. The seed liquid was inserted, the inoculation amount was 2% (v / v), and culture was carried out, the cultu...

Embodiment 2

[0051] Fermentation enzyme production medium formula Glucose: 2.0%, yeast powder: 0.7% (NH 4 ) 2 SO 4 : 0.5%, KCl: 1.0%, K 2 HPO 4 12H 2 O: 0.05%, NaH 2 PO 4 2H 2 O: 0.05%, MgSO 4 : 0.01%, prepared with tap water, adjusted to pH 6.5 with HCl.

[0052] Take 1000mL of culture medium, evenly distribute it in ten 500mL Erlenmeyer flasks, and sterilize. Insert the slant strain Bacillus subtilis ZJB-063, cultivate the thallus for 50 hours, and then collect the thallines by centrifugation. These thallines are added to 500 mL of p-hydroxybenzonitrile aqueous solution, and the final substrate concentration is 3 g / L. The cells hydrolyze p-hydroxyphenylacetonitrile; reaction conditions: temperature 33°C, initial pH 6.8, transformation time 4h, shaker speed 100r / min. Detected by high performance liquid chromatography, the conversion rate of p-hydroxyphenylacetonitrile was 100%. The transformation solution was centrifuged to remove cells, filtered, and the transformation solutio...

Embodiment 3

[0054] Liquid seed culture medium is the same as embodiment 1.

[0055] Fermentation enzyme production medium: glucose: 0.5%, yeast powder: 2%, urea: 0.4g%, sodium glutamate: 0.1%, K 2 HPO 4 : 0.01%, KH 2 PO 4 : 0.01%, (NH 4 ) 2 SO 4 : 1.0%, MgSO 4 : 0.01%, pH natural.

[0056] Take 100mL of liquid seed culture medium, evenly distribute it in two 250mL Erlenmeyer flasks, and sterilize. Insert the slant strain Bacillus subtilis ZJB-063, cultivate the bacterial body, shake the rotating speed of 150r / min, and cultivate it at 28°C for 36h as the seed liquid, and set aside.

[0057] Take 2L of the above-mentioned fermentation medium, put it into 20 500mL shake flasks equally, and sterilize. The seed solution was inserted, the inoculum amount was 4% (v / v), and culture was carried out, the culture temperature was 28° C., the culture time was 60 h, and the shaker speed was 150 r / min.

[0058] Collect the thalline by centrifugation at 9000r / min, wash twice with distilled wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com