Preparation method for highly effective maleic anhydride series polymer antisludging agent

A technology of maleic anhydride and scale inhibitor, which is applied in the field of preparation of high-efficiency maleic anhydride polymer scale inhibitor, can solve the problem of high solubility and achieve the effect of high solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

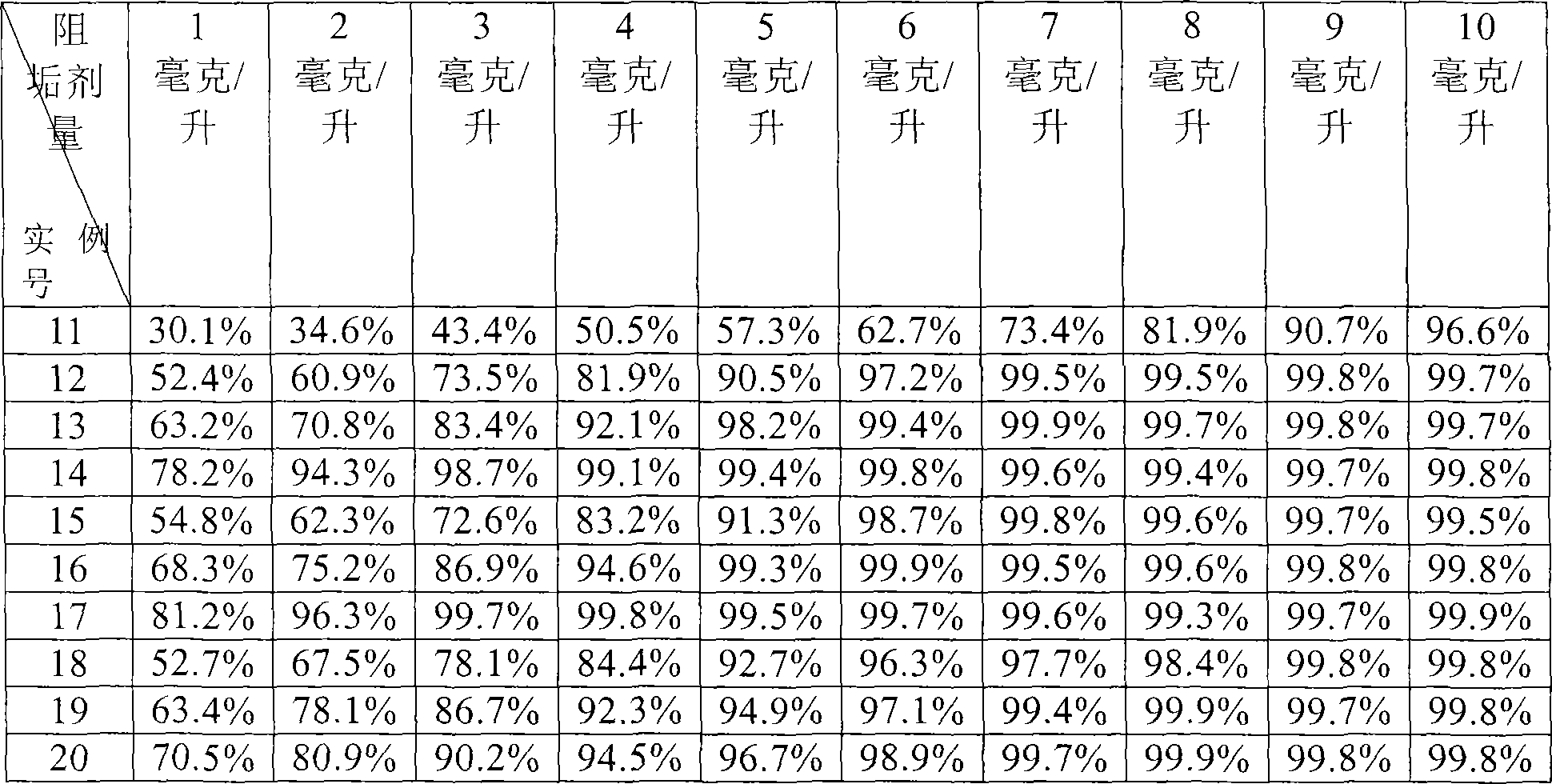

Examples

Embodiment 1

[0034] Synthesis of Hyperbranched Polyester

[0035] Weigh 0.1 mole of 2,2-bis(hydroxymethyl)propionic acid, 4 mg of trimethylolpropane, 0.02 gram of toluenesulfonic acid catalyst, and move into a four-necked flask equipped with a thermometer, a stirrer, and a reflux condenser , melted and polymerized at 140°C for 5 hours, then precipitated and filtered with 500 ml of acetone, and dried at 50°C for 24 hours to obtain a white powdery hyperbranched polyester solid for future use.

Embodiment 2

[0037] Synthesis of Hyperbranched Polyester

[0038] Add 0.15 moles of dibasic acid anhydride to a three-necked flask equipped with a spherical condenser, a constant pressure funnel, and electric stirring, use tetraethylammonium bromide as a catalyst and 40 milliliters of 1N, N-dimethylformamide, and heat up to 80°C-110°C, after dissolving into a homogeneous phase, slowly drop 0.1 mole of glycidyl alcohol into the system, the reaction process is tracked by the acid value, and the material is discharged when the acid value is constant. Precipitate, separate and purify with water / petroleum ether, and dry in a vacuum oven at 55°C-60°C for 24 hours to obtain hyperbranched polyester for use.

Embodiment 3

[0040] Synthesis of Hyperbranched Polyethers

[0041] Add 40 ml of dichloromethane and 0.1 mole of 3-ethyl-3-hydroxymethylbutene oxide to a two-necked round-bottomed flask that is vacuum-dried, filled with nitrogen, and equipped with a stirring bar, and 0.6 mg of trigger is added with a micro-syringe Agent boron trifluoride etherate complex, the polymerization reaction started at 25 ℃. After the predetermined reaction time is reached, the dichloromethane solution dissolved in phenol is added to the reaction system with a syringe, and the stirring is continued for 3 hours. The mixed solution was washed with distilled water until neutral, the polymer was precipitated and filtered in excess petroleum ether, and the obtained hyperbranched polyether sample was dried at 40°C for 24 hours for use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com