Method for developing potassium fluoroboric beryllium acid / sodium crystal through hydrothermal method

A technology of potassium fluoroboronate and single crystal is applied in the field of optoelectronic materials, and can solve the problems of difficulty in obtaining c-direction crystals, unfavorable applications, poor crystal quality and the like, and achieve the effects of being beneficial to application, low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

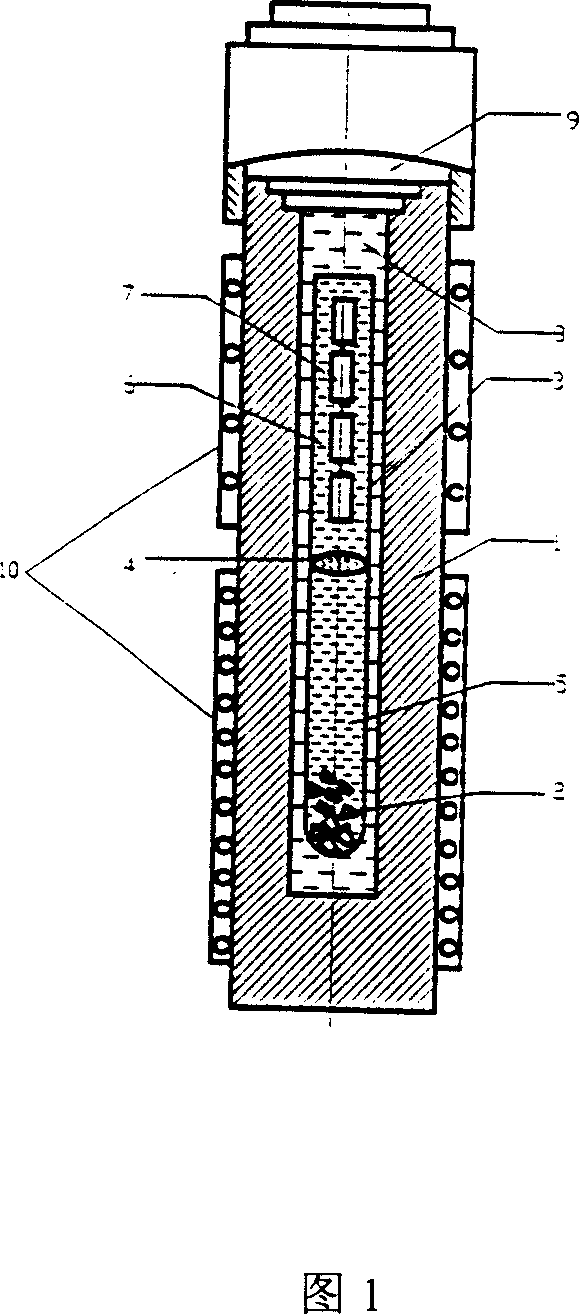

Embodiment 1

[0026]20 g of broken KBBF wafers obtained by spontaneous crystallization by the molten salt method (which are 10 mm × 20 mm × (2-3) mm KBBF grown by the molten salt method and broken to particles with a particle size of 2-4 mm) were used as nutrients, placed in In an autoclave with a gold-lined self-tightening seal structure with a reaction chamber size of 24mm×180mm, deionized water (ie, no mineralizer) was added to a fullness of 60%. A gold baffle with openings at the center and edges with a porosity of 7% is placed in the middle and lower part of the gold bushing to separate the raw material dissolution zone in the lower part from the growth zone in the upper part. The c-direction KBBF seed crystal is suspended on the top of the gold bushing, and the seed crystal is processed by molten salt method crystal growth. The gold bushing is then sealed and placed in an autoclave. In order to keep the internal and external pressure balance of the gold bushing, an appropriate amoun...

experiment example 2

[0028] 250 g of broken chips of KBBF obtained by spontaneous crystallization by the molten salt method (which are 10 mm × 20 mm × (2-3) mm KBBF grown by the molten salt method and broken to particles with a particle size of 2-4 mm) were used as nutrients, placed in The size of the reaction chamber is 42mm×760mm in an autoclave with a self-tightening seal structure with a gold lining, and the H 3 BO 3 47g is used as the mineralizer, and deionized water is added according to the fullness of 70%, so that the concentration of the deionized aqueous solution of the mineralizer is 2.0mol / L, and the pH value is 4.0. A gold baffle with openings at the center and edges with a porosity of 7% is placed in the middle and lower part of the gold bushing to separate the raw material dissolution zone in the lower part from the growth zone in the upper part. The c-direction KBBF seed crystal is suspended on the top of the gold bushing, and the seed crystal is processed by molten salt method ...

experiment example 3

[0030] 250 g of broken chips of KBBF obtained by spontaneous crystallization by the molten salt method (which are 10 mm × 20 mm × (2-3) mm KBBF grown by the molten salt method and broken to particles with a particle size of 2-4 mm) were used as nutrients, placed in In an autoclave with a self-tightening seal structure with a gold lining and a reaction chamber size of 60mm×1200mm, put KF90g as a mineralizer, and add deionized water at a fullness of 80% to make the mineralizer deionized The concentration of the aqueous solution is 1.0 mol / L, and the pH value is 8.0. A gold baffle with holes in the center and edges and a porosity of 10% is placed in the middle and lower part of the gold bushing to separate the raw material dissolution zone in the lower part from the growth zone in the upper part. The c-direction KBBF seed crystal is suspended on the top of the gold bushing, and the seed crystal is processed by molten salt method crystal growth. The gold bushing is then sealed a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com