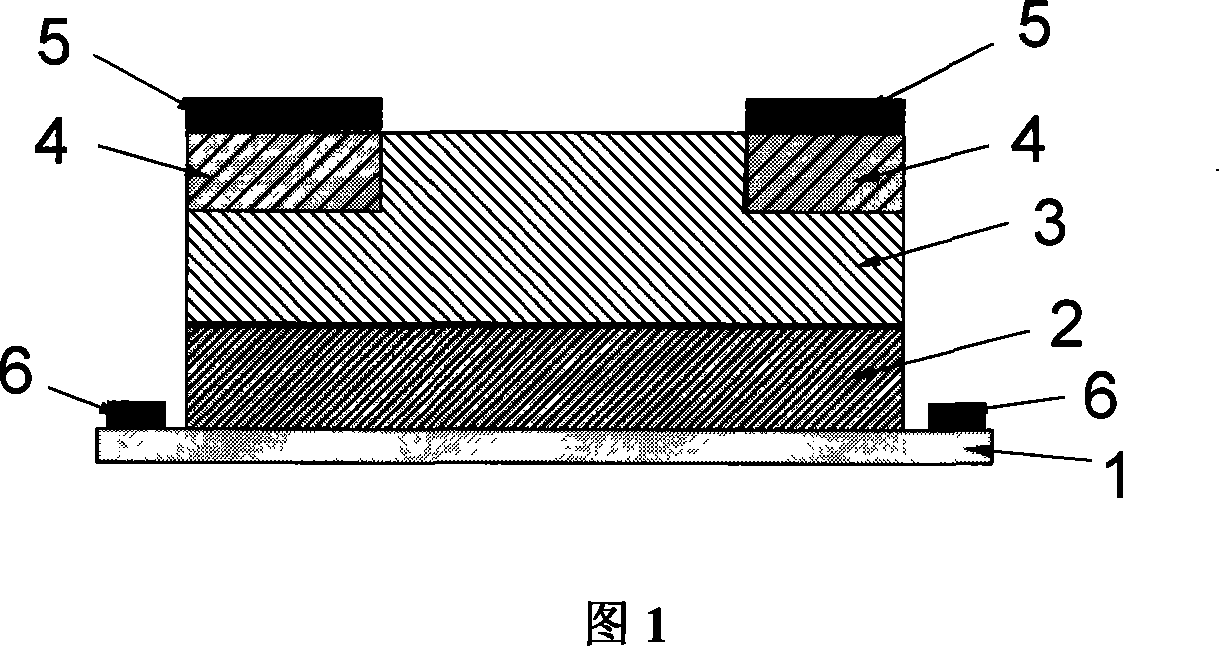

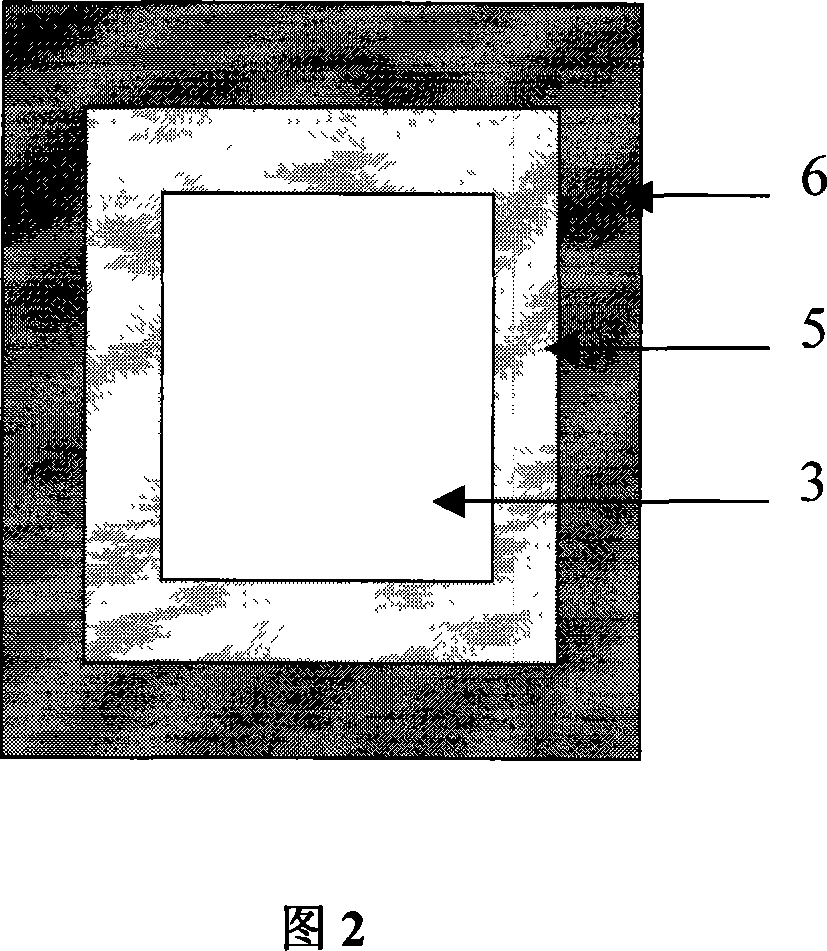

A PIN structure TiO2 base ultraviolet detector and its making method

An ultraviolet detector and detector technology, applied in the direction of semiconductor devices, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problems of difficult to obtain P-type TiO conductive materials, difficulties, etc., and achieve simple and mature preparation process, easy to use The effect of long life and fast response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

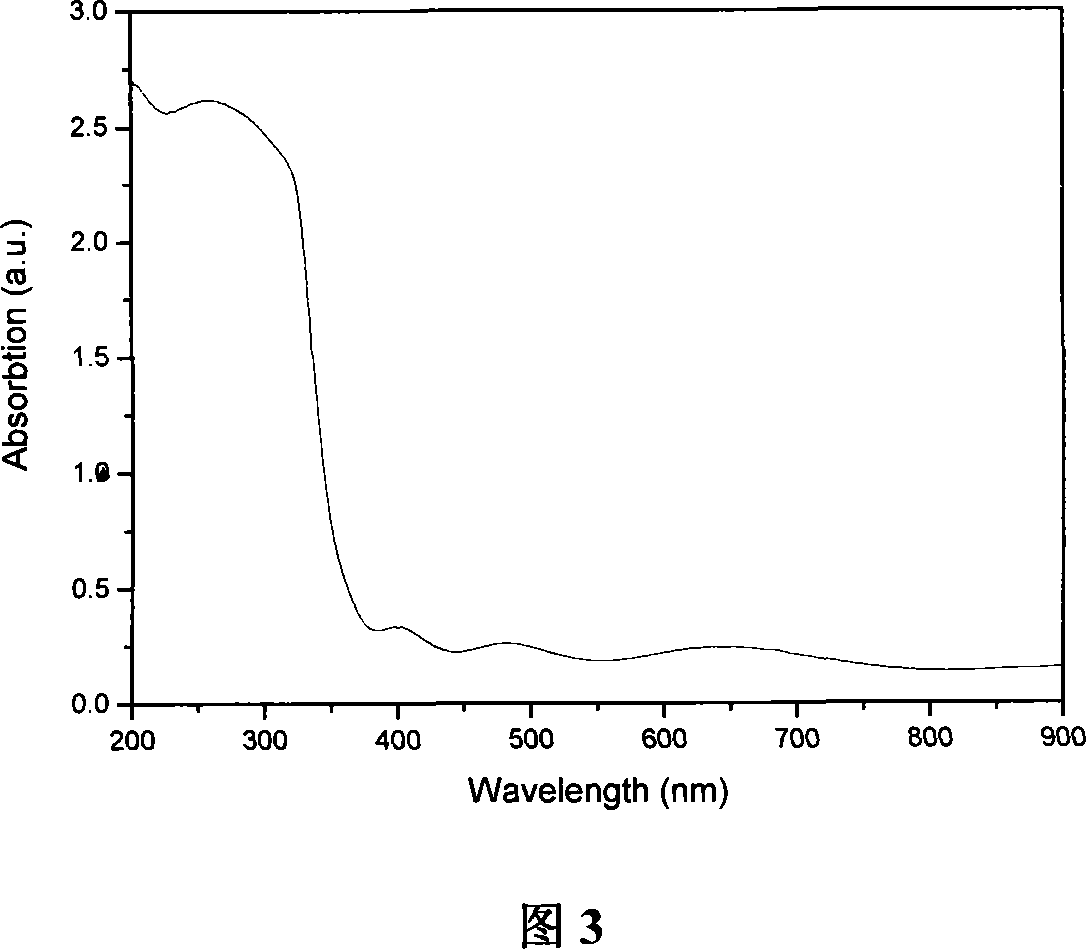

[0038] Intrinsic TiO 2 Preparation of sol: tetrabutyl titanate as the precursor. Tetrabutyl titanate and diethanolamine are dissolved in absolute ethanol (60% of the total amount), and stirred for 30-60 minutes to obtain a mixed solution. In addition, deionized water and absolute ethanol (40% of the total amount) are mixed uniformly, and then dropped into the above mixed solution drop by drop under constant stirring. After the addition, continue to stir for 30-120 minutes to obtain a uniform and transparent Light yellow TiO 2 Sol. The ratio of reactants: tetrabutyl titanate: absolute ethanol: deionized water: diethanolamine=20:100:1:6 (volume ratio).

[0039] Preparation of ZnO: Al sol: a certain amount of (CH 3 COO) 2 Zn·2H 2 O is dissolved in a mixed solution of ethylene glycol methyl ether and monoethanolamine (MEA), [Zn 2+ ]: [MEA] = 1:1, prepared into a mixed solution with a zinc ion concentration of 0.5-1.0 mol / L. Then, fully stir in a water bath at 50-70°C for 1-5 hours to ...

Embodiment 2

[0050] TiO 2 :Preparation of Zn sol: Add an appropriate amount of Zn(NO 3 ) 2 Dissolve in 20-40ml of absolute ethanol, add 10-15ml of tetrabutyl titanate and 3-4.5ml of diethanolamine, and stir for 30-120min to obtain a mixed solution. In addition, mix 0.5-1ml deionized water and 10-30ml absolute ethanol evenly, drop them into the above mixed solution dropwise under constant stirring, and continue stirring for 30-120min after the dropwise addition to obtain uniform and transparent TiO 2 : Zn sol. The volume ratio of the reactants: tetrabutyl titanate: absolute ethanol: deionized water: diethanolamine = 20:100:1:6.

[0051] The pretreatment method of the conductive substrate is the same as in Example 1.

[0052] Use tin foil as a mask to cover the edges of the pre-processed ITO conductive glass with a width of 2mm. The N-type ZnO:Al film is prepared by the electron beam evaporation method. The specific method is: select ZnO powder with a purity of 99.7%, mix with alumina powder wit...

Embodiment 3

[0057] Intrinsic TiO 2 The preparation of the sol and the pretreatment of the conductive substrate are the same as in Example 1.

[0058] Use tin foil as a mask to cover the edges of the pre-processed ITO conductive glass with a width of 2mm. A 10nm thick In film was deposited on the ITO conductive glass by thermal evaporation. Using high-purity diethyl zinc (purity>991999%) as the zinc source, O 2 (Purity>991999%) as oxygen source, N 2 As a carrier gas (purity>991999%), a ZnO film with a thickness of 0.1-1 μm is prepared on the In film by chemical vapor deposition. The growth chamber pressure is 133Pa, and the growth temperature is 350-550°C. After deposition, the prepared ZnO / In film is heat-treated at 600-1000° C. for 30-120 minutes to obtain an N-type ZnO:In film.

[0059] Using the preparation method of Example 1, the intrinsic TiO with a thickness of 0.2-2 μm was prepared on the N-type ZnO:In film 2 Active layer. Using dry etching technology to prepare the intrinsic TiO 2 Pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Electron concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com