Cylindrical member and process for producing the same

A manufacturing method and technology of cylindrical body, which can be applied in the direction of prosthesis, textiles and papermaking, and devices with tubular structure of human body, etc. It can solve the problems of large differences in blood vessels, achieve excellent elastic recovery rate, excellent attachment growth, and cell infiltration excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0107] The present invention is illustrated in detail based on the following examples. However, the present invention is not limited to these Examples.

[0108] (1) The polymers used in this example are as follows.

[0109] PLGA (50 / 50): lactic acid (50mol%)-glycolic acid (50mol%) copolymer, intrinsic viscosity = 1.08dL / g (in HFIP, 30°C) manufactured by Absorbable Polymers International,

[0110] PLCA (77 / 23): lactic acid (77mol%)-caprolactone (23mol%) copolymer, Mw=2.5×10 5 , Manufactured by Taki Chemical Co., Ltd.,

[0111] PLCA (68 / 32): lactic acid (68mol%)-polycaprolactone (32mol%) copolymer, Mw=1.75×10 5 , Manufactured by Taki Chemical Co., Ltd.,

[0112] Vinyl chloride, ethanol: Wako Pure Chemical Industries, Ltd.

[0113] (2) The physical properties of the cylinder were measured by the following methods.

[0114] Average fiber diameter: Measured at 20 locations with a digital microscope (KEYENCE, VHX DIGITALMICROSCOPE), the average value thereof was taken as the a...

reference example 2

[0133] Reference Example 2 (Manufacture of Cylindrical Body A)

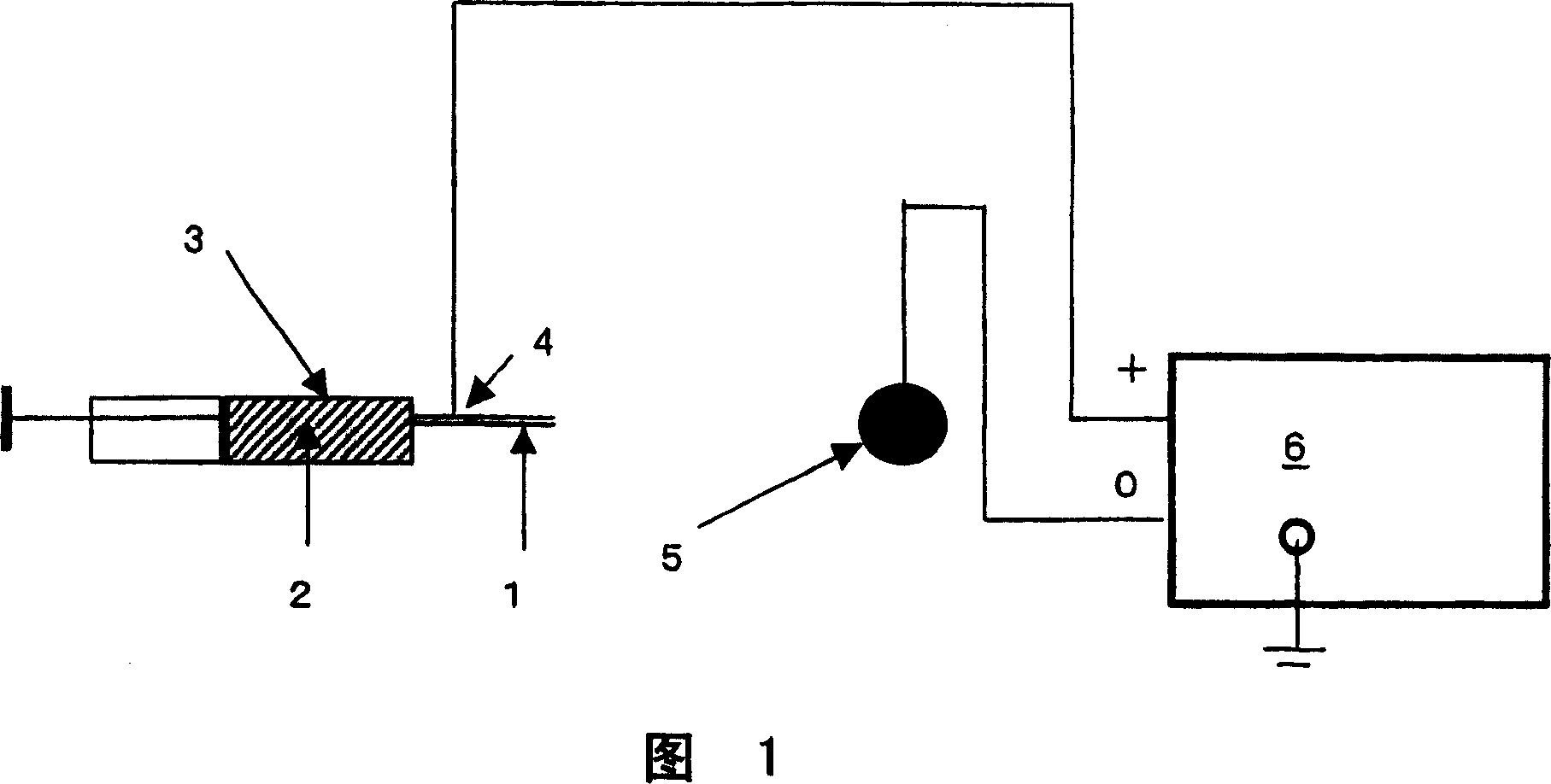

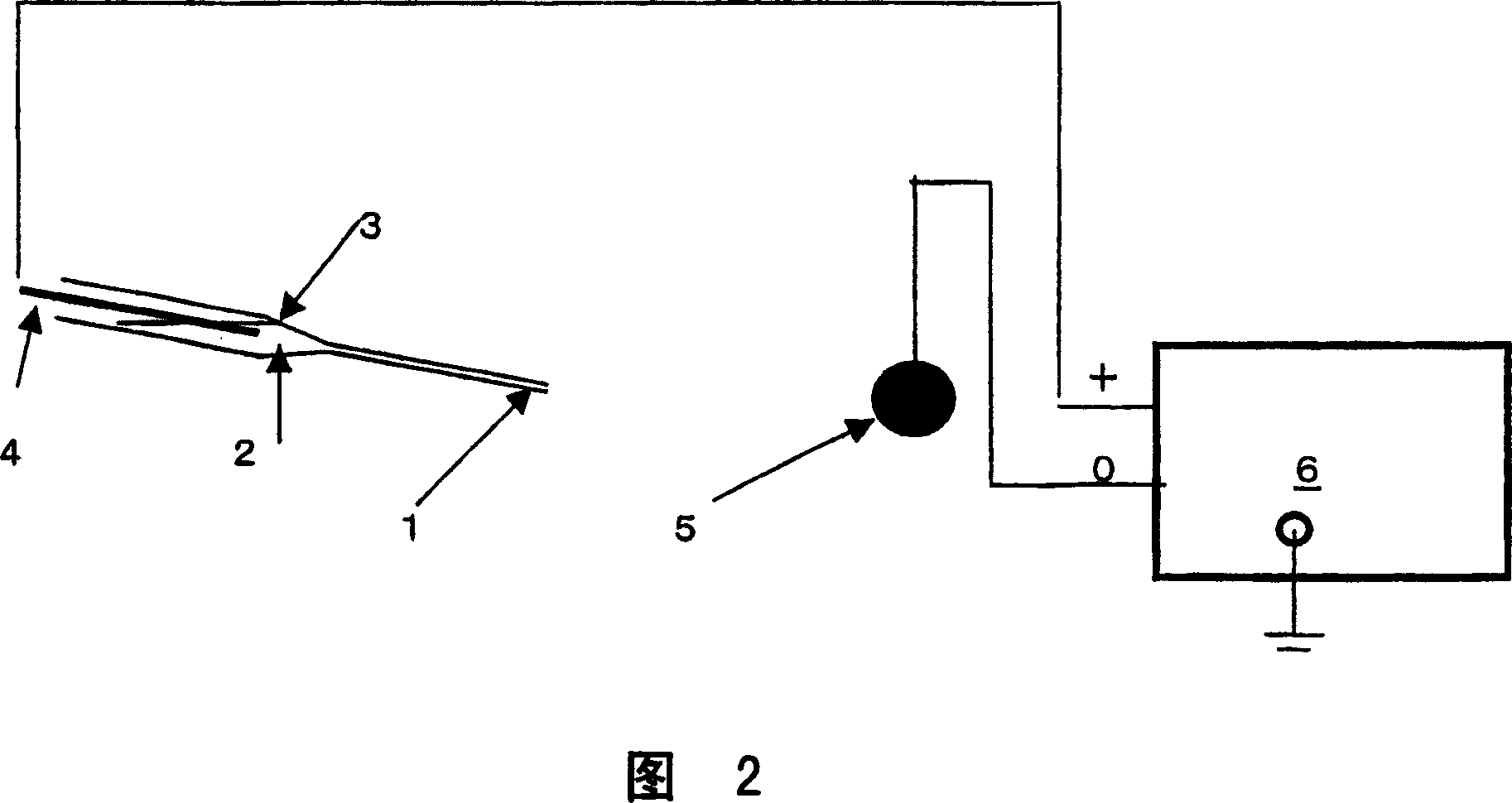

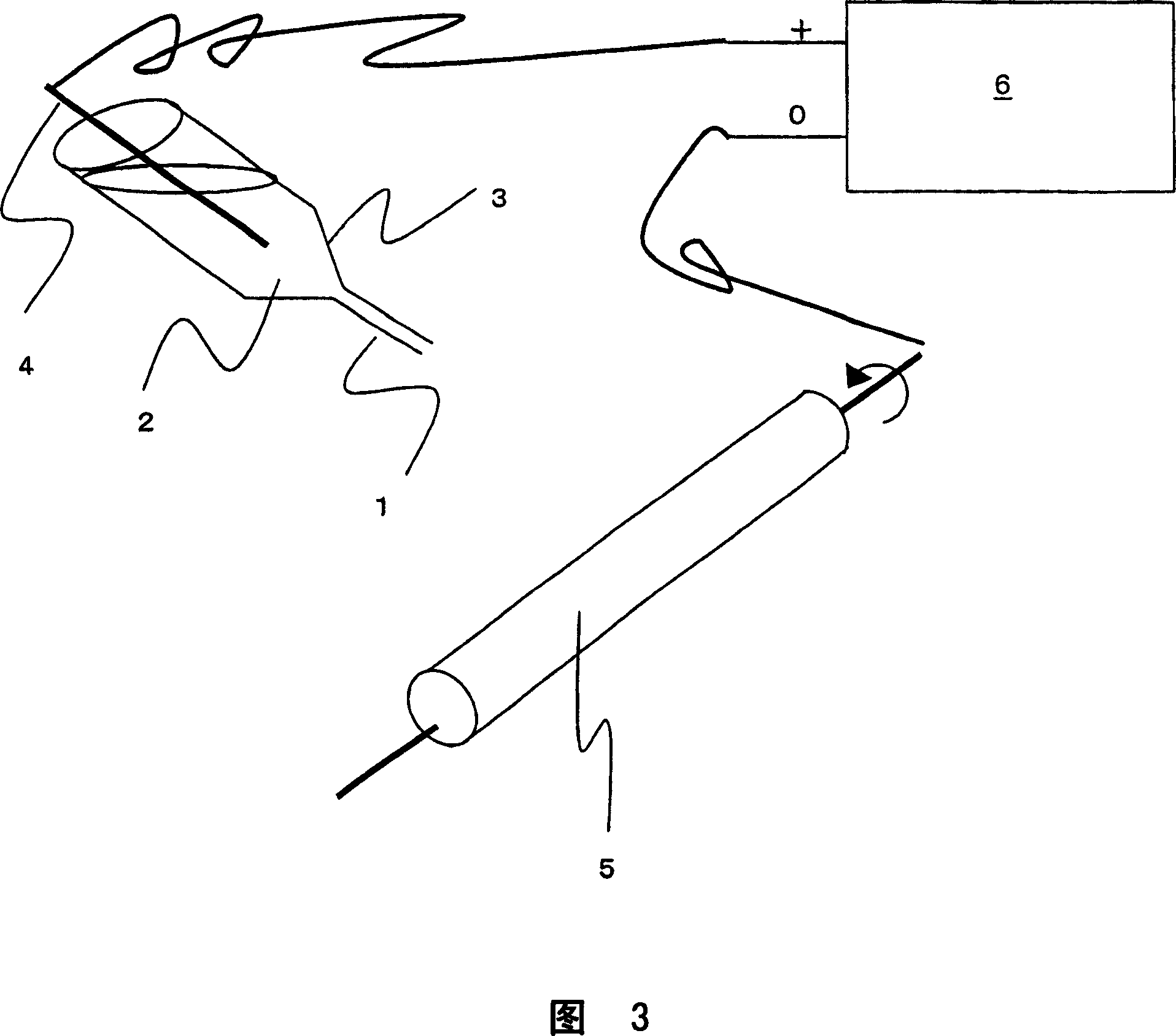

[0134] Assemble the device shown in Figure 2. The inner diameter of the nozzle 1 is 0.8 mm. The distance from the nozzle 1 to the collecting-side electrode 5 was set at 10 cm. As the collection-side electrode 5 , a stainless steel rod with an outer diameter of 4 mm and a length of 20 cm was used.

[0135] The spinning stock solution A is put into the holding tank 3, the voltage between the discharge side electrode 4 and the collecting side electrode 5 is set to 1 kV, and the collecting side electrode 5 is rotated at 100 rpm while the spinning stock solution A is It was sprayed toward the collecting-side electrode 5 for 5 minutes, and a cylindrical body A was obtained. Repeat the same operation to obtain five cylinders A. The average fiber diameter of the fibers constituting the cylindrical body A is 4 μm, the length of the cylindrical body A is 10 cm, the outer diameter is 4.1 to 4.2 mm, the inner diameter is...

reference example 3

[0136] Reference example 3 (manufacture of cylindrical body B)

[0137] The operation of Reference Example 2 was repeated except that the spinning stock solution B was used instead of the spinning stock solution A, and the cylindrical body B was produced. The average fiber diameter of the fibers constituting the cylindrical body B is 4 μm, the length of the cylindrical body B is 10 cm, the outer diameter is 4.1 to 4.2 mm, the inner diameter is 4 to 4.1 mm, and the thickness is 90 to 110 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com