Environment protection method of handling industrial abandoned phosphorized liquid

An environmental protection treatment and phosphating solution technology, applied in chemical instruments and methods, inorganic pigment treatment, water/sewage multi-stage treatment, etc., can solve problems such as red tide, environmental pollution, waste of resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

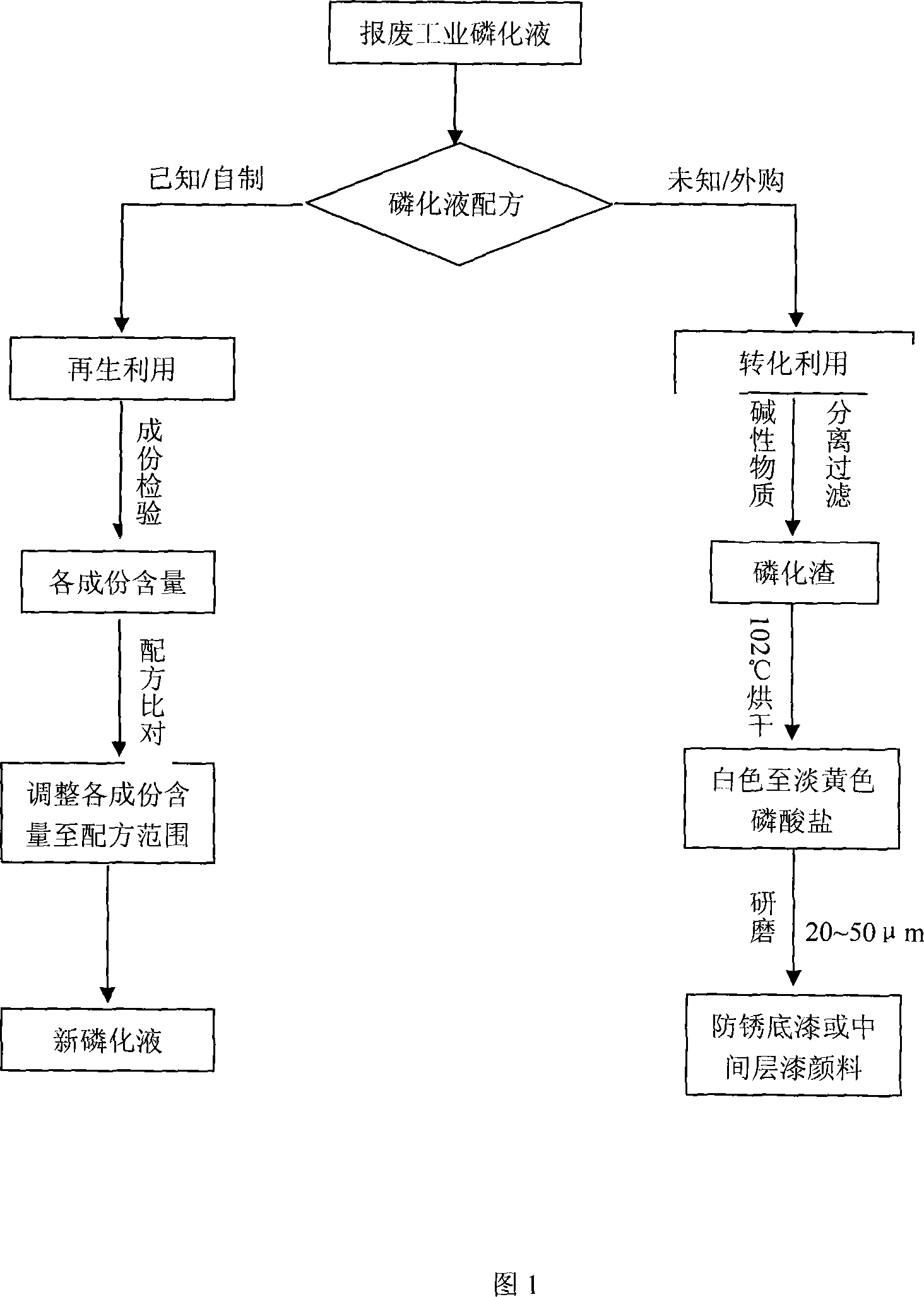

Method used

Image

Examples

Embodiment 1

[0075] Regeneration of waste phosphating solution

[0076] To regenerate 3 tons of scrapped "medium temperature zinc-manganese phosphating solution" with known main components, the operation process is as follows:

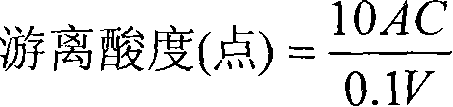

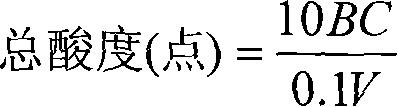

[0077] 1. Determination of free acidity and total acidity

[0078] By acid-base titration. Take 10ml of the sample and titrate it with 0.1mol / L sodium hydroxide standard solution, and the number of milliliters consumed is represented by points.

[0079] (1) Reagent

[0080] Sodium hydroxide: 0.1mol / L standard solution.

[0081] Methyl orange (or bromophenol blue): indicator.

[0082] Phenolphthalein: indicator.

[0083] (2) Inspection method

[0084] Free acidity: Use a pipette to draw 10ml of phosphating solution into a 250ml Erlenmeyer flask, add 50ml of distilled water, and add 2-3 drops of methyl orange (or bromophenol blue) indicator. Titrate with sodium hydroxide standard solution until the solution turns orange (or titrate with bromophenol blue indica...

Embodiment 2

[0226] Waste phosphating solution is converted into anti-rust primer pigment:

[0227] The waste phosphating solution with unknown formula is treated by making anti-rust primer pigments, and transformed into new products, which are applied in industrial production.

[0228] The specific conversion process is as follows:

[0229] Waste phosphating solution+alkaline substances (calcium oxide, calcium hydroxide or sodium hydroxide, etc.)→full stirring→precipitation and filtration→washing the sediment to PH6-7→drying at 102°C→light yellow to white phosphate→crushing and grinding to 20-50μm → anti-rust primer or intermediate layer paint pigment.

[0230]Take one ton of waste phosphating solution (acidic), add appropriate amount of alkaline substances, adjust the pH value to 8-10, fully stir, let stand, separate and filter, the filtrate can be used as reclaimed water in industrial production, and the filter residue can be used as anti-corrosion Rust pigment, washed with water to P...

Embodiment 3

[0240] Regeneration of waste phosphating solution

[0241] To regenerate 1 ton of scrapped "low temperature zinc-based phosphating solution" with known main components, the inspection process of each main component is as follows:

[0242] 1. Determination of free acidity and total acidity

[0243] By acid-base titration. Take 10ml of the sample and titrate it with 0.1mol / L sodium hydroxide standard solution, and the number of milliliters consumed is represented by points.

[0244] (1) reagent and equipment are identical with embodiment 1

[0245] (2) Inspection method

[0246] Free acidity: Use a pipette to draw 10ml of phosphating solution into a 250ml Erlenmeyer flask, add 50ml of distilled water, and add 2-3 drops of methyl orange (or bromophenol blue) indicator. Titrate with sodium hydroxide standard solution until the solution turns orange (or titrate with bromophenol blue indicator until it changes from yellow to blue-purple), which is the end point. Write down the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com