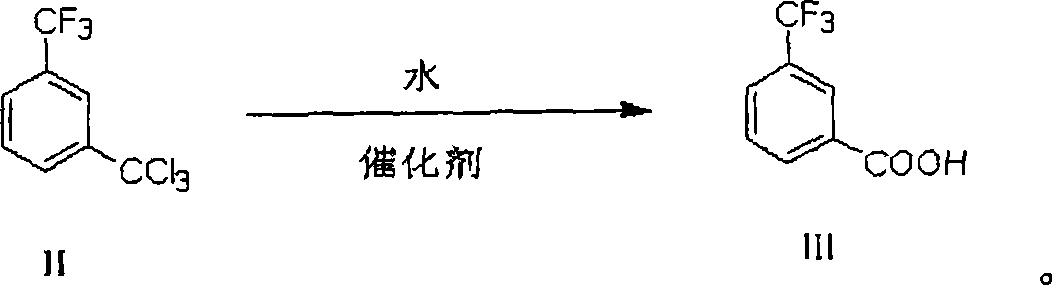

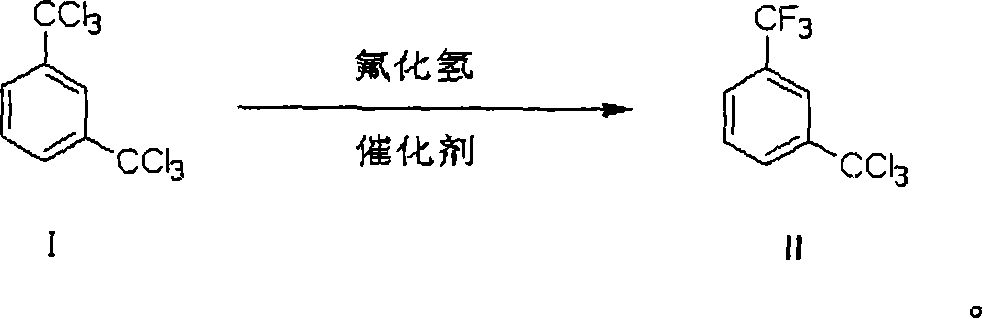

Process of preparing 3-trifluoromethyl benzoic acid

A technology of trifluoromethylbenzoic acid and trichloromethyltrifluoromethylbenzene, which is applied in the field of preparation of 3-trifluoromethylbenzoic acid, can solve problems such as unfavorable industrial production, affecting product purity, and difficulty in obtaining raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

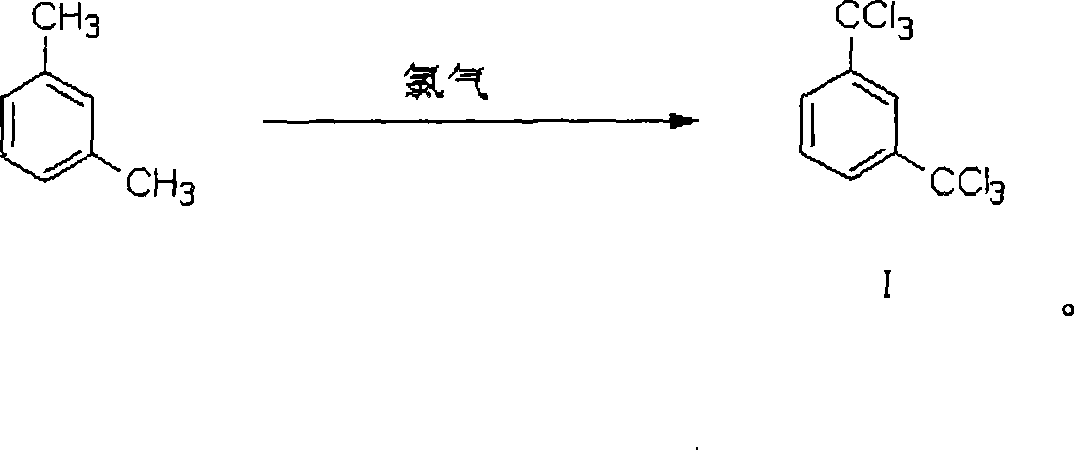

[0064] Preparation of m-Ditrichloromethylbenzene

[0065] After mixing 563 mol parts of m-ditrichloromethylbenzene and 1689 mol parts of m-xylene, the temperature in the reactor was raised to 120°C, then the ultraviolet lamp was turned on, chlorine gas was introduced, and the temperature in the reactor was maintained at 120-140°C. The reaction proceeded for 30 hours. According to the analysis by gas chromatograph, the content of m-dichloromethyltrichloromethylbenzene, an intermediate of the chlorination reaction, is less than 0.5%. Measured by GC-MS method, the reaction product is m-dichloromethylbenzene.

[0066] Degas under reduced pressure, and distill the reaction liquid under reduced pressure. Collect the fractions at 154-158℃ / 10mmHg to obtain 2068 parts of m-ditrichloromethylbenzene. The yield of the chlorination reaction is 89.3%. The purity of benzene is 97.2%.

Embodiment 2-9

[0068] Preparation of m-Ditrichloromethylbenzene

[0069] It was carried out in the same manner as in Example 1, except that the reaction temperature, raw material ratio and reaction time were as shown in Table 1. Table 1 also shows the yield and purity of m-ditrichloromethylbenzene and the content of high boilers in the resulting product.

[0070] In addition, Example 8 used 2% by weight of azobisisobutyronitrile (based on the weight of meta-xylene) as the initiator instead of UV initiation.

Embodiment 9

[0071] Example 9 uses 2% by weight of benzoyl peroxide (based on the weight of meta-xylene) as the initiator instead of UV initiation.

[0072] Implement

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com