Method for preparing polyolefin microporous-film supported gel polymer electrolyte film

A technology of polyolefin microporous film and electrolyte film, applied in chemical instruments and methods, secondary battery parts, synthetic resin layered products, etc., can solve the impact of lithium-ion battery cycle performance and safety performance, mechanical performance decline, Lithium electrode passivation failure and other problems, to achieve the effect of improving electrochemical stability, improving contact performance, and equipment compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

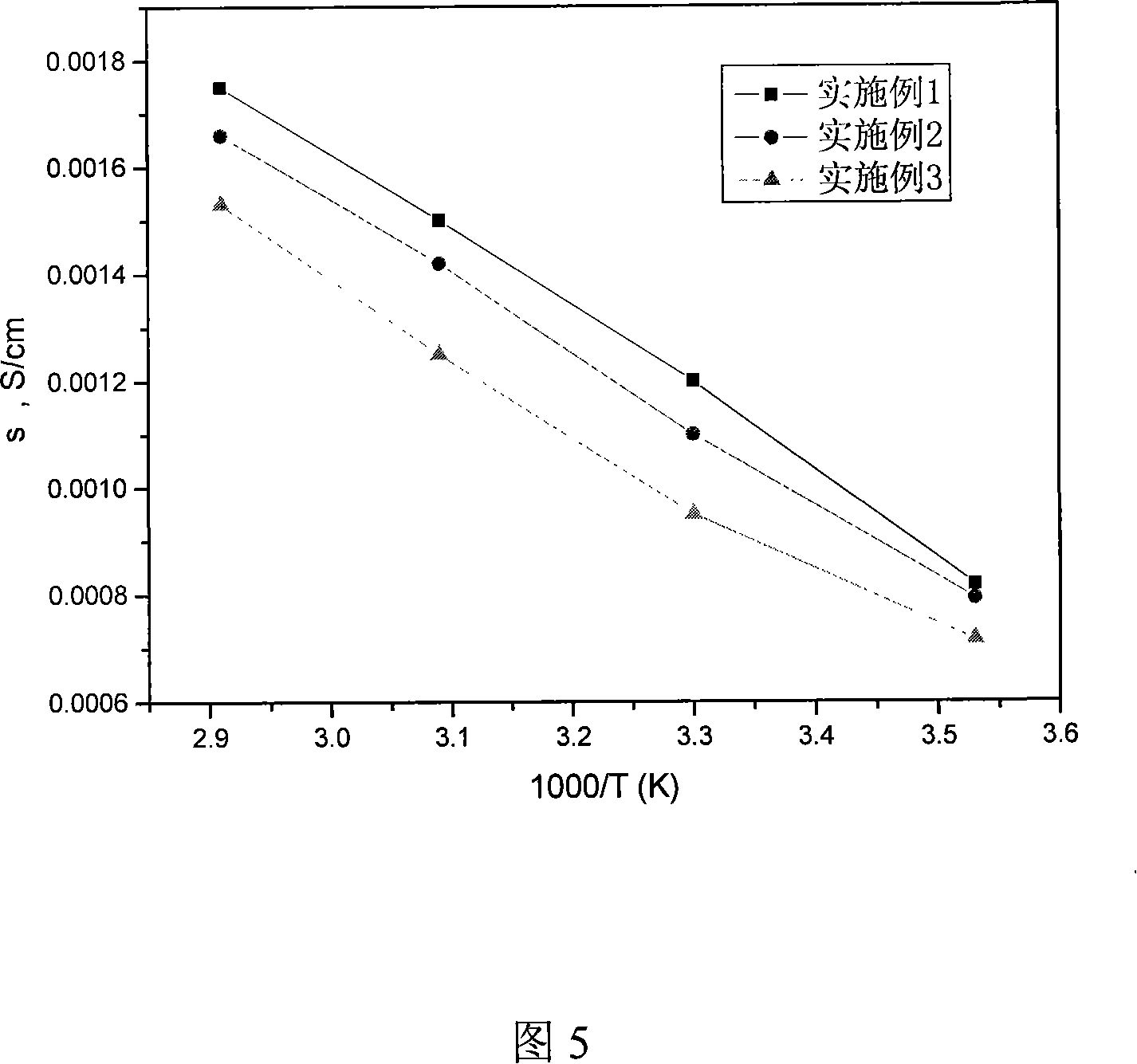

Embodiment 1

[0019] 1) 3g (0.03mol) of methyl methacrylate and 2.48g (0.01mol) of methacryloxypropyltrimethoxysilane were blended and dissolved in 40ml of toluene solvent, and 0.0384g of benzoyl peroxide was added as After the initiator was stirred until it was completely dissolved, it was reacted with magnetic stirring at 78° C. for 10 hours under a nitrogen atmosphere. After the reaction, it was cooled to room temperature and precipitated with petroleum ether to obtain a methyl methacrylate-methacryloxypropyl trimethoxysilane copolymer, which was then filtered and vacuum-dried at 50° C. for 8 hours.

[0020] 2) Mix 2.08g (0.01mol) of tetraethyl orthosilicate and 0.72g (0.04mol) of deionized water evenly, then add 0.0014g of p-toluenesulfonic acid as a hydrolysis catalyst, perform hydrolysis reaction for 15 minutes with ultrasonic oscillation, and obtain orthosilicon acid hydrolyzate;

[0021] 3) Blend and dissolve 1g of methyl methacrylate-methacryloxypropyl trimethoxysilane copolymer a...

Embodiment 2

[0028] 1) 5g (0.05mol) of methyl methacrylate and 2.48g (0.01mol) of methacryloxypropyltrimethoxysilane were blended and dissolved in 40ml of toluene solvent, and 0.052g of benzoyl peroxide was added as After the initiator was stirred until it was completely dissolved, it was reacted with magnetic stirring at 70° C. for 10 hours under a nitrogen atmosphere. After the reaction, it was cooled to room temperature and precipitated with petroleum ether to obtain a methyl methacrylate-methacryloxypropyl trimethoxysilane copolymer, which was then filtered and vacuum-dried at 50° C. for 8 hours.

[0029] 2) Mix 2.08g (0.01mol) tetraethyl orthosilicate and 0.54g (0.03mol) deionized water evenly, then add 0.0014g p-toluenesulfonic acid as a hydrolysis catalyst, perform hydrolysis reaction for 15 minutes with ultrasonic vibration, and obtain orthosilicon acid hydrolyzate;

[0030] 3) Blend and dissolve 1g of methyl methacrylate-methacryloxypropyl trimethoxysilane copolymer and 0.2g of e...

Embodiment 3

[0035] 1) 10g (0.1mol) of methyl methacrylate and 2.48g (0.01mol) of methacryloxypropyltrimethoxysilane were blended and dissolved in 40ml of toluene solvent, and 0.087g of benzoyl peroxide was added as After the initiator was stirred until it was completely dissolved, it was reacted with magnetic stirring at 80° C. for 10 hours under a nitrogen atmosphere. After the reaction, it was cooled to room temperature and precipitated with petroleum ether to obtain a methyl methacrylate-methacryloxypropyl trimethoxysilane copolymer, which was then filtered and vacuum-dried at 50° C. for 8 hours.

[0036] 2) with embodiment 1 step 2)

[0037] 3) 1g of methyl methacrylate-methacryloxypropyl trimethoxysilane copolymer and 0.15g of ethyl orthosilicate hydrolyzate were blended and dissolved in 12ml of tetrahydrofuran solvent, and 0.01g of deionized water and 0.01g of p-toluenesulfonic acid, fully stirred, then heated to 50°C for hydrolysis and condensation reaction for 2 hours, to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Ionic conductivity | aaaaa | aaaaa |

| Ionic conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com