Phase-variable microcapsule and its production

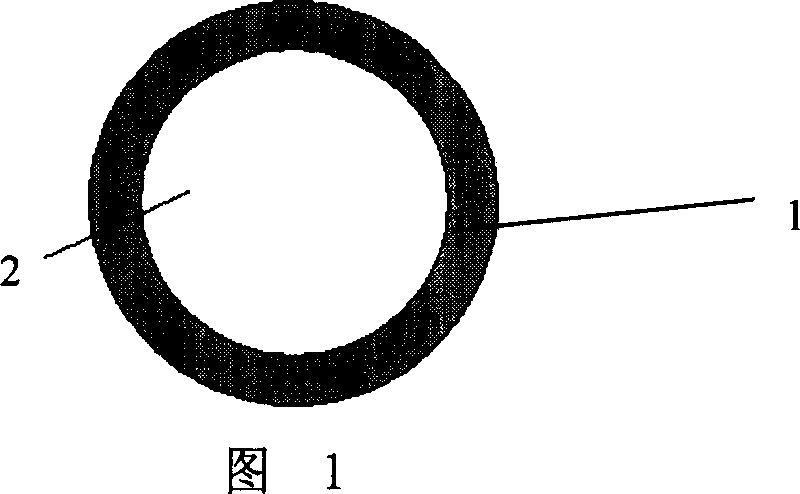

A phase change microcapsule and phase transition technology, applied in microcapsule preparation, microsphere preparation, etc., can solve the problems of uneven thickness of microcapsule shell, easy independent nucleation of polymers, etc., and achieve good compactness and wide melting point range. , good heat resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Dissolve 1g of thermosetting phenolic resin in 30g of ethyl acetate, then add 1g of hexadecane to form an organic solution. In a 100ml three-necked flask, add 20g of deionized water and 0.4g of gum arabic, stir to dissolve, emulsify 15g of the above organic solution at 30°C at a speed of 3000rpm, and add 20g of deionized water after emulsification for one hour After dilution, the resulting thin emulsion was evaporated under reduced pressure at 30°C for 40 minutes.

[0024] The above emulsion with the solvent evaporated was transferred to a high-pressure reactor, solidified in an oven at 150°C for 6 hours, and then naturally cooled to room temperature. The obtained microcapsule dispersion was centrifuged, washed three times with deionized water, washed once with ethanol and ethyl acetate, and finally dried in a vacuum oven at 50°C for 10 hours to obtain microcapsules.

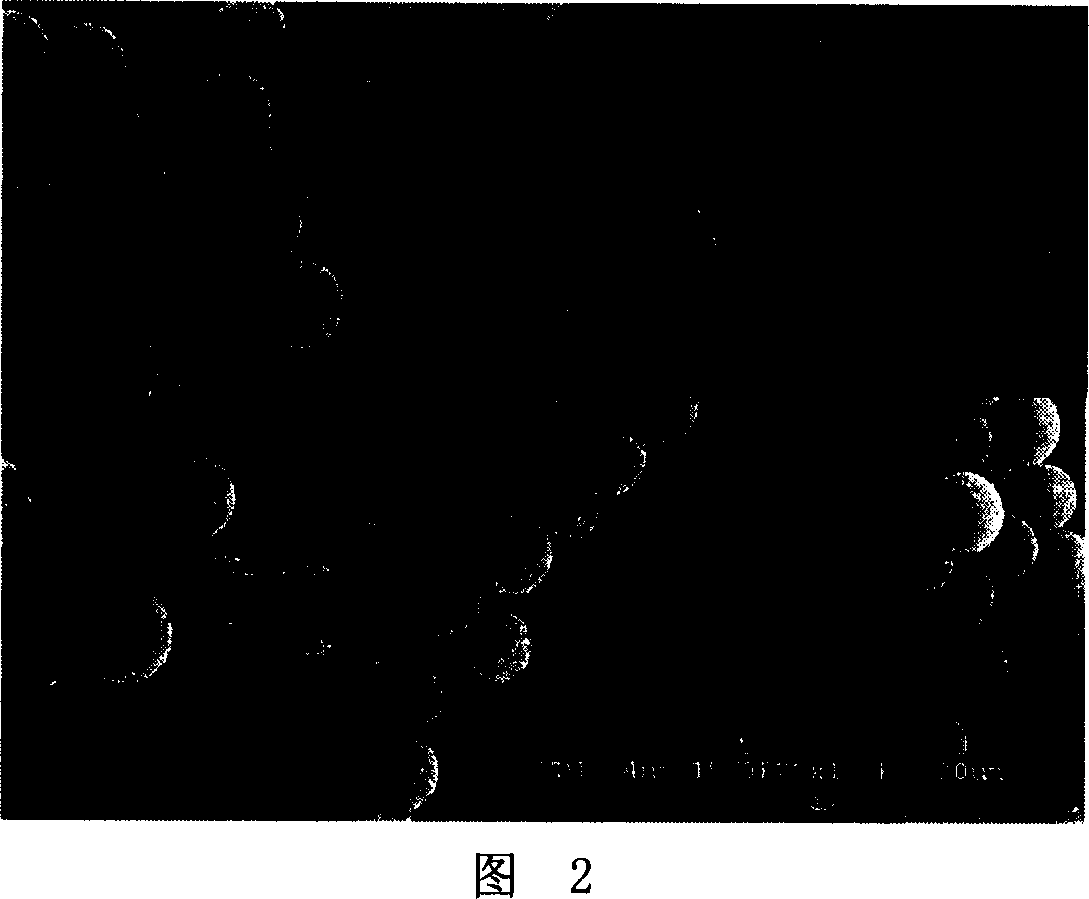

[0025] The SEM photo of the obtained microcapsules is shown in Figure 2. The illustration in the figu...

Embodiment 2

[0028] Dissolve 2g of thermosetting phenolic resin in 30g of ethyl acetate, then add 1g of hexadecane to form an organic solution. In a 250ml three-necked flask, add 50g of deionized water and 1g of gum arabic. After stirring and dissolving, emulsify 30g of the above organic solution at 30°C at a speed of 3000rpm. After emulsifying for one hour, add 50g of deionized water to dilute. The resulting dilute emulsion was evaporated under reduced pressure at 30°C for 40 minutes.

[0029] The above emulsion with the solvent evaporated was transferred to a high-pressure reactor, solidified in an oven at 150°C for 6 hours, and then naturally cooled to room temperature. The obtained microcapsule dispersion was centrifuged, washed three times with deionized water, washed once with ethanol and ethyl acetate, and finally dried in a vacuum oven at 50° C. for 10 hours to obtain microcapsules.

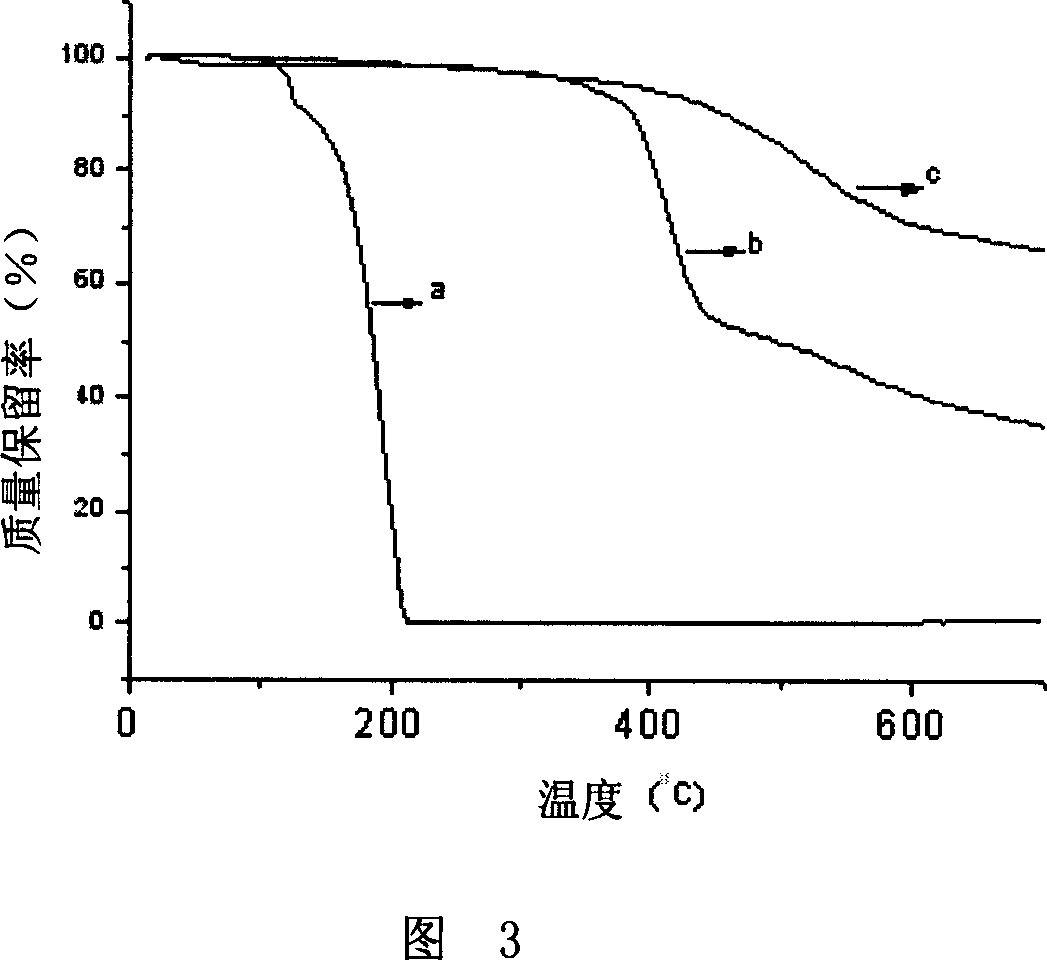

[0030] The latent heat of phase change of the obtained microcapsules was 86.3 J / g, and the latent...

Embodiment 3

[0032] Dissolve 0.4g of thermosetting phenolic resin in 30g of ethyl acetate, then add 1g of hexadecane to form an organic solution. In a 100ml three-necked flask, add 20g of deionized water and 0.4g of gum arabic, stir to dissolve, and emulsify 15g of the above organic solution at 30°C at a speed of 3000rpm. After emulsification for one hour, add 20g of deionized water to dilute , The obtained dilute emulsion was distilled at 30° C. under reduced pressure for 40 minutes.

[0033] The above emulsion with the solvent evaporated was transferred to a high-pressure reactor, solidified in an oven at 150°C for 6 hours, and then naturally cooled to room temperature. The obtained microcapsule dispersion was centrifuged, washed three times with deionized water, and washed once with ethanol and ethyl acetate respectively. Finally, dry in a vacuum oven at 50° C. for 10 hours to obtain microcapsules.

[0034] Due to the thin wall of the obtained microcapsules, most of the capsule shells...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Latent heat of phase change | aaaaa | aaaaa |

| Latent heat of phase change | aaaaa | aaaaa |

| Latent heat of phase change | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com