Lignin-base nano carbon fibre and preparation method thereof

A nano-carbon fiber and lignin-based technology, applied in the field of nano-carbon fiber and its preparation, can solve the problems of difficult mass production of nano-carbon fiber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

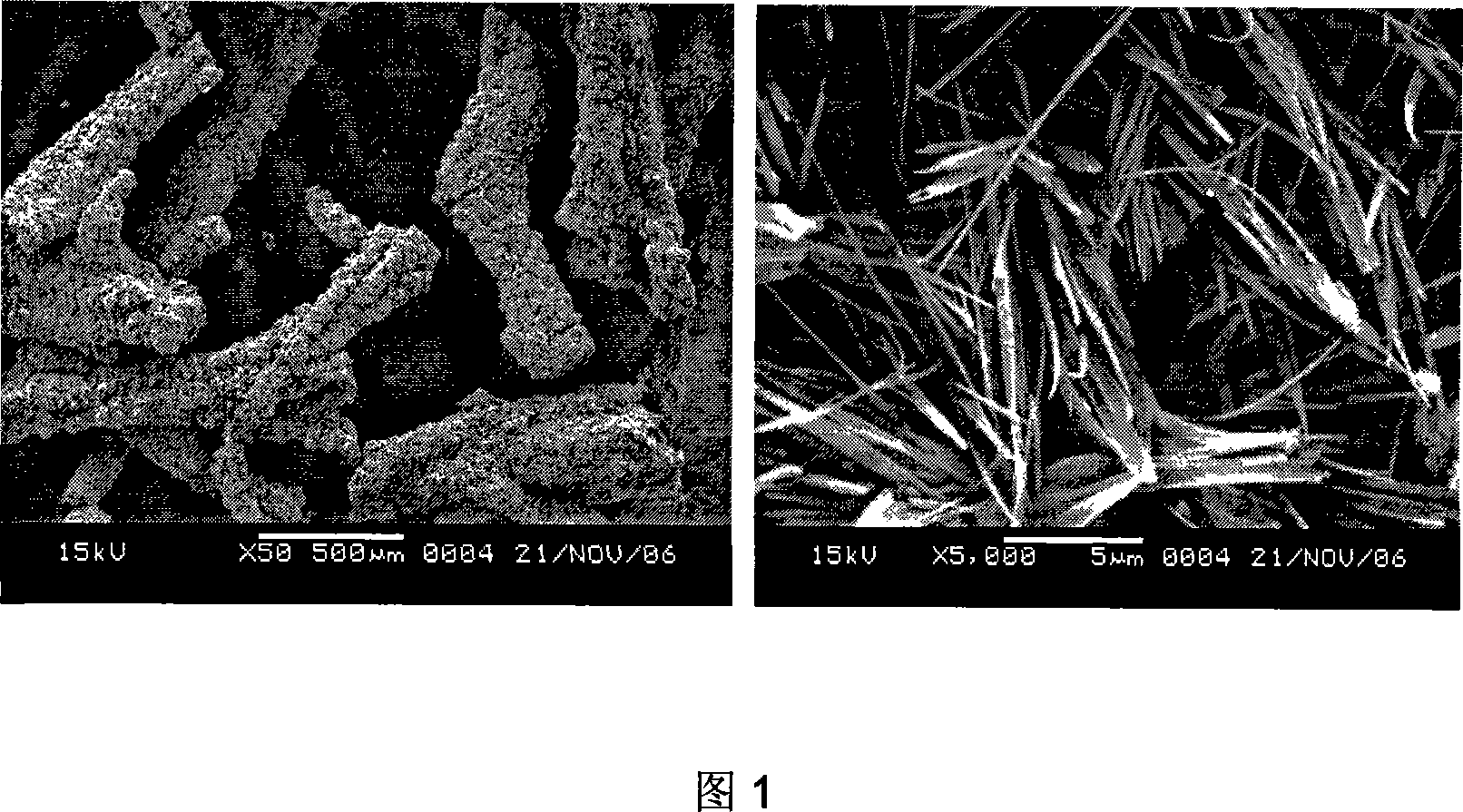

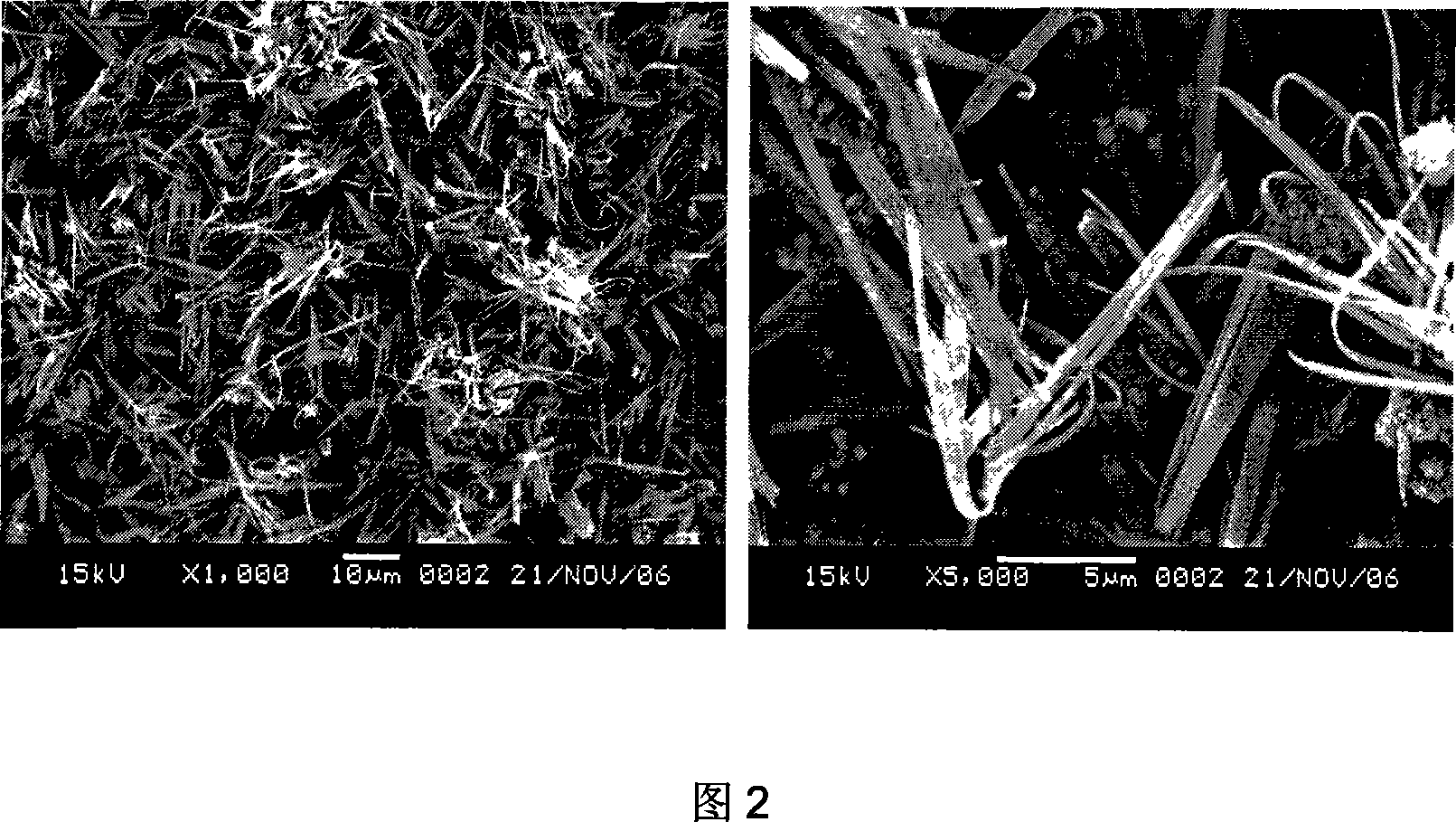

[0018] Alkali lignin powder and polybutylene terephthalate were pre-crystallized in a drying oven for 8h at a temperature of 80°C, and the alkali lignin powder and polybutylene terephthalate were mixed in a ratio of 25 / 75 (mass ratio), put it into a vacuum drying oven and dry for 48h at a temperature of 120°C. Blending and banburying in a twin-screw blender, slicing, and obtaining blended slicing. Blended fibers are obtained by melt spinning. It was placed in a protective atmosphere furnace and pre-oxidized in air at a heating rate of 3°C / min to 250°C for 1 hour. Carbonization was carried out under the protection of nitrogen gas flow. The heating rate is 3°C / min, the temperature is raised to 1000°C, and the carbonization process is 3 hours. Cool to room temperature to obtain carbon nanofibers. SEM analysis showed ( FIGS. 1 and 2 ) that the obtained carbon nanofibers had a diameter of 50-200 nm and a length of 5-10 μm.

Embodiment 2

[0020] Alkali lignin powder and polypropylene were pre-crystallized in a drying oven for 8 hours at a temperature of 100°C. The alkali lignin powder and polypropylene were taken in a ratio of 25 / 75 (mass ratio), and dried in a vacuum drying oven for 48 hours at a temperature of 150°C. Blending and banburying in a twin-screw blender, slicing, and obtaining blended slicing. Blended fibers are obtained by melt spinning. It was placed in a protective atmosphere furnace and pre-oxidized in air at a heating rate of 3°C / min to 200°C for 3 hours. Carbonization was carried out under the protection of nitrogen gas flow. The heating rate is 3°C / min, the temperature is raised to 1000°C, and the carbonization process is 5 hours. Cool to room temperature to obtain carbon nanofibers. The obtained carbon nanofibers have a diameter of 50-200 nm and a length of 5-10 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com