Preparation method of doped modified ferric phosphate lithium

A lithium iron phosphate modification technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., to achieve obvious effect of doping modification and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

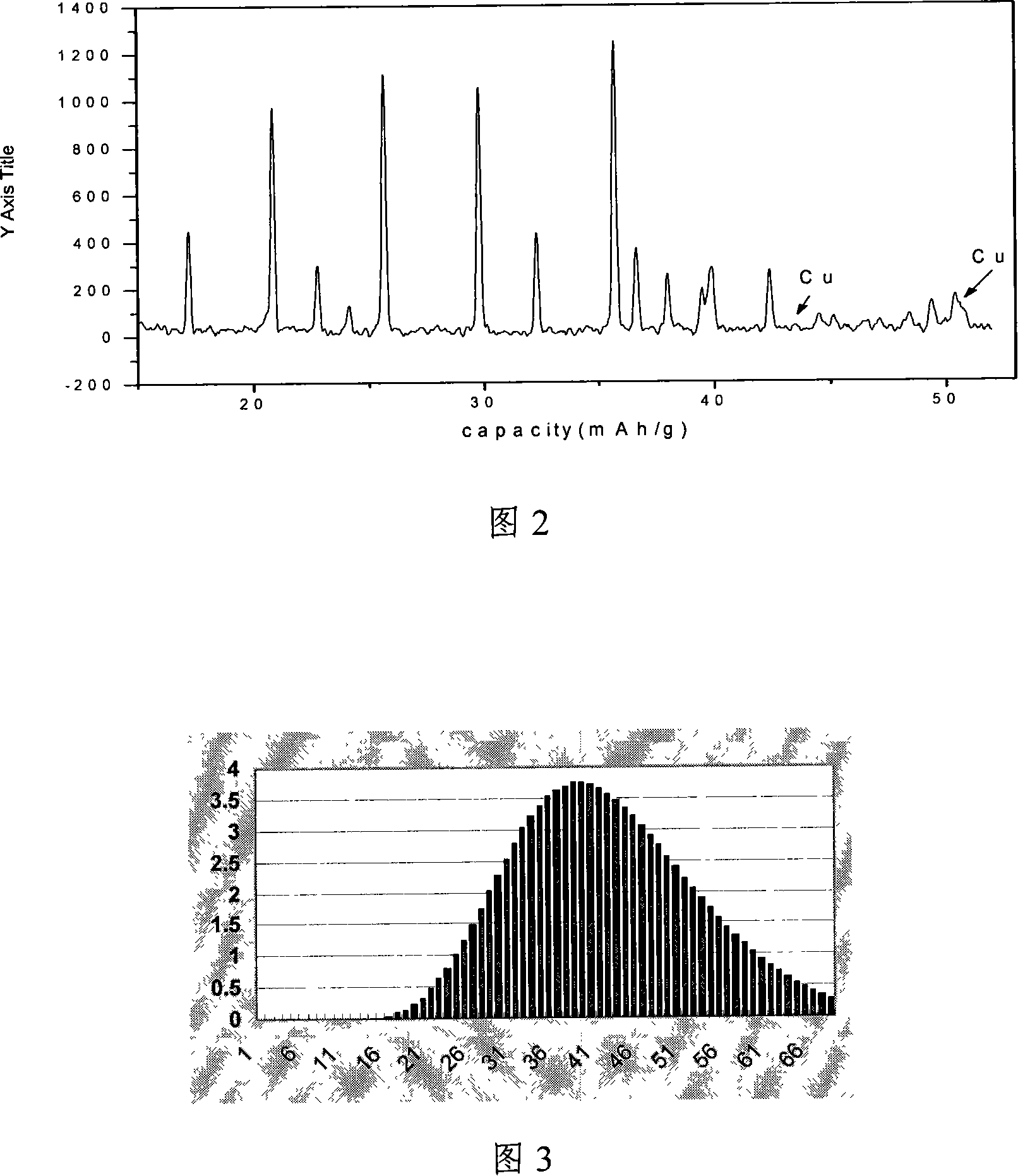

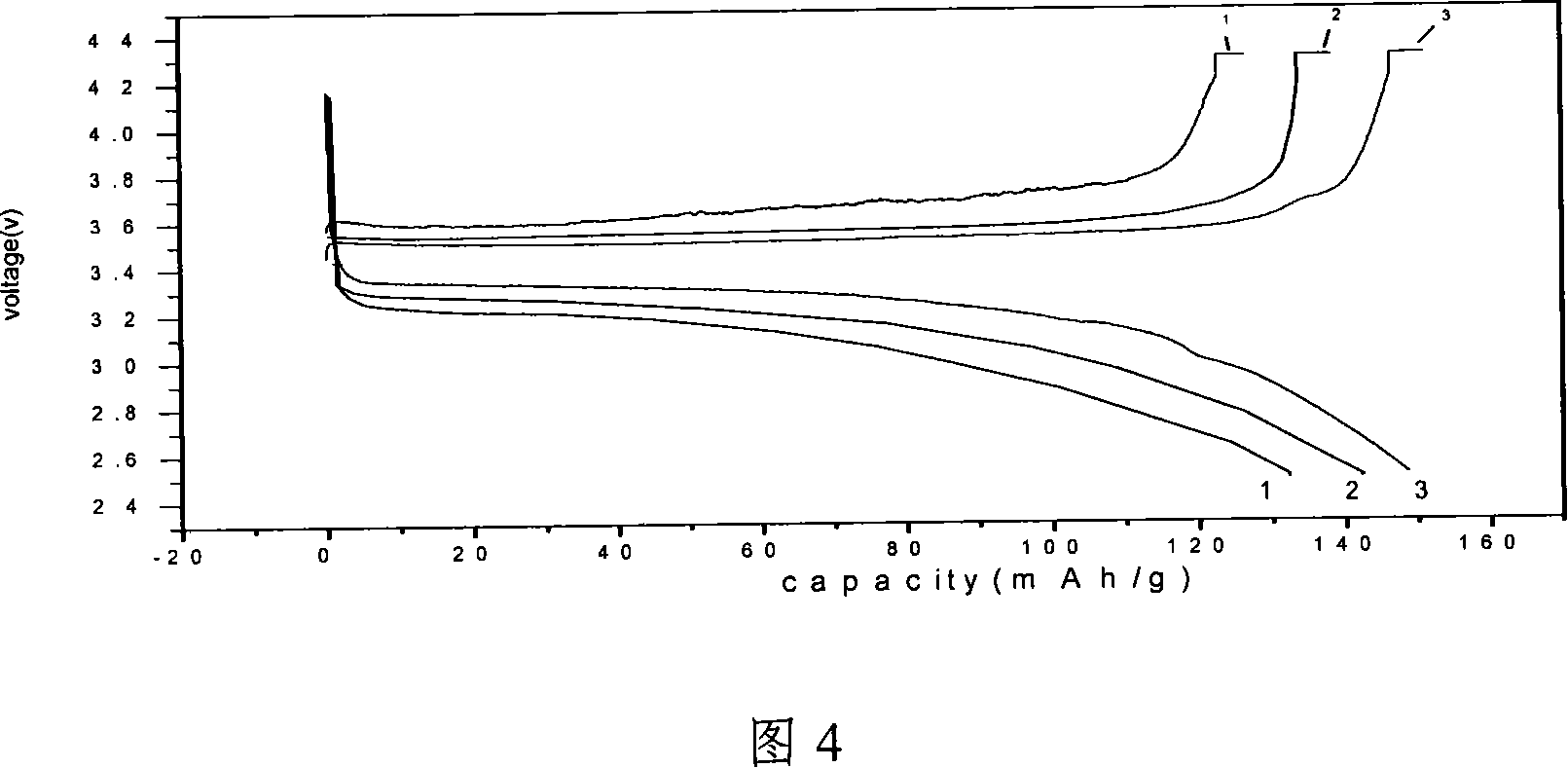

[0016] Add 150ml of deionized water and 5.2ml of 85% phosphoric acid (0.1mol) into the reaction kettle, put it on the electric heating mantle and heat it to 80°C, add 1.5g of copper oxide powder, and dissolve the copper oxide under electric stirring. Then add 5.6g of reduced iron powder, and add 10 agate beads with a diameter of 3mm, insert a reflux tube, and react under a nitrogen atmosphere, and control the reaction process through the pH value. When the pH value reaches 3.5, weigh 4.196 g of lithium hydroxide and dissolve it in 150 ml of deionized water. Slowly add it dropwise into the reaction kettle, continue the reaction, and stop the reaction after monitoring the pH value to 6.8. The precursor was obtained after the reaction product was spray-dried. The precursor was calcined at 750 °C for 12 hours under a nitrogen atmosphere, and then the doped modified LiFePO was obtained after natural cooling. 4 .

[0017] The traditional solid-phase synthesis technology is diffic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com